Auger drilling at the dacha

Need a well under the water, but do not know what method to apply for its construction? You need to choose the most simple, inexpensive and efficient way, for example, drilling with machines like LBU 50.

What is the construction of water wells with the use of this equipment, what advantages are typical for such structures and by what equipment are these wells equipped? We will answer these and similar questions within this article.

Features of drilling using a blade tool

Drilling with the use of augers is widely used to create deep wells under water at the dacha and household plots. Soil sampling with machines such as CO 2Vili LBU 50 is carried out using a blade tool.

The drilling process is very similar to drilling holes in the winter fishing. The cutter, scrolling around its axis, crashes into hard rock and thus goes deep into. At the same time, the selected rock is brought out by the screw, thanks to which the walls of the well are ideally even.

In comparison with the rotary drilling method, auger soil sampling allows drilling of wells in soft and hard rocks with a depth of over thirty meters. As a result, this method is considered the best solution for the construction of autonomous water supply systems for country houses and country houses.

Despite the fact that the technology of auger drilling has been known for a long time, it is still considered to be one of the most productive in comparison with other known techniques.

Well drilling equipment

Auger-type drilling rigs are most often mounted on the chassis of trucks, due to which optimal equipment mobility is achieved. In addition, such installations are easy to control, so that during one work shift, professional workers perform a passage of up to ten meters or more.

Important: Despite its many advantages, this drilling equipment is not insured against a number of operational difficulties due to the condition of the ground in the area. For example, a screw for drilling wells can rest on an underground boulder, strong enough to negate all the work previously done. Again, regardless of the power of the equipment, rarely any installation is able to bypass or pierce the moraine.

Drilling with auger equipment is popular and in demand by professionals and novice specialists because of the specific features of the workflow. The destruction of the rock and its selection are two different processes that are carried out using one blade blade without the need for additional equipment. As a result, time and money are saved.

Summarizing the above, we note the advantages of auger drilling and the disadvantages that need special attention.

Advantages of the method:

- mobility and the ability to deliver equipment to areas that do not have specially equipped access roads;

- the ability to perform the whole complex of works using a single drilling rig;

- the possibility of drilling wells of different depths, starting from the pits for the installation of support pillars and ending with intake artesian wells;

- fitness equipment to work with different types of soil;

- the relative ease of use of the units, and therefore no need for highly qualified personnel;

- reasonable price of the work;

- deadlines for well construction.

Are there any disadvantages? The disadvantage of this method is one - it is the inability of the equipment to the passage of solid rocks. The drill may get stuck or deformed if it encounters a massive boulder at depth. Therefore, the use of these installations is recommended in areas with soft soil or medium hard soils.

Arrangement of borehole pumps of screw type

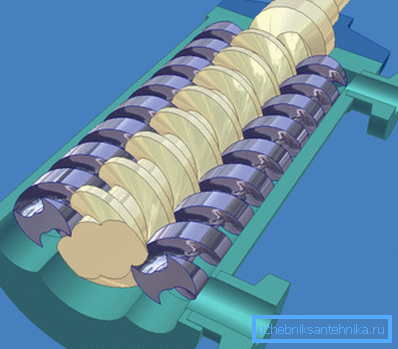

The technology of transportation of this or that environment by means of screw blades is in demand not only during drilling, but also during well development. For example, a downhole screw pump that sinks into most modern water wells of various depths. Consider the features of the operation of these devices.

At the moment, three types of submersible pumps are commonly used: centrifugal, vortex and auger pumps for wells. All of these modifications have characteristic advantages and features that you should pay attention to when choosing.

But it is the samples of auger action that demonstrate the greatest reliability and durability in comparison with more complex in operation and repair centrifugal modifications.

The principle of operation of this type of downhole equipment is as follows. In the case of the device there is a drive with screw blades. The blades, spinning, set in motion a liquid medium. Due to the increase or decrease in the number of revolutions of the screw blade for a certain period of time, the intensity of the water supply changes.

Due to structural features, submersible pumps of this type can be given a cylindrical shape with a small cross-section diameter of 80-120 mm. This characteristic greatly simplifies the process of immersing the device into the cavity of the well.

The maximum pressure of such pumps on average reaches 70-100 meters with the highest performance up to 60 liters of water per minute.

Important: The weight of the device is comparable to the mass of centrifugal analogues. Therefore, for the installation of such devices is also used reliable metal cable, one end of which is attached to the eyebolt on the top cap.

Screw submersible pumps for wells demonstrate the following advantages:

- profitability;

- more affordable cost compared to centrifugal counterparts;

- long resource;

- ease of operation and maintenance;

- the possibility of mounting their own hands;

- maintainability.

Conclusion

Thanks to the use of auger equipment in the construction and construction of mines, it became possible to simplify the process of extracting water. Due to the use of these technologies, the instruction for the construction of autonomous water supply systems is not as complicated as when using other less simple equipment to use.

You can find more useful and interesting information by watching the video in this article.