Automation for borehole pumps: the basics of water supply

Properly selected well pump with automation is the "heart" of the entire water supply system. At the same time, the operation of an automatic unit is no less important than the functioning of the water-lifting part itself.

In our article we describe the basic principles by which the work of such equipment is regulated, and we give some tips that will be useful to the masters in the independent design and assembly of systems.

Basics of automatic control

A pump installed in the well itself is able to efficiently perform only one function, namely, to lift water to a predetermined height. However, it is always necessary to work in this mode unless pumping a well.

At all other times, it is important that the flow of water is controlled.

- Naturally, manually adjusting the operation of the pumping system will not work, since the pump is located underground at a considerable depth.. For this reason, the control is carried out on the principle of feedback - the automation for a well pump perceives certain parameters, and accordingly makes adjustments to the operation of the pump.

- An example of such adjustment may be the engine start pump when the pressure in the system. As soon as the water flow leads to a decrease in pressure, information is fed to the control unit and pumping is started.

Note! To make it happen less often, and not after each switching on of the crane, a special receiver is installed in the system. Due to the design features, it ensures smooth start-up, which greatly saves the resource of the pump part.

- Accumulators work in exactly the same way.: As soon as the tank is filled to a certain level, the pump is turned off and the water supply is interrupted.

- An important task of pump automation is device protection.: if necessary (work without water, sand or silt contamination) it turns off, which prevents it from breaking. Given that the price for high-quality models rather big, this feature can be very useful.

Below we will look at the adjustment examples mentioned here in more detail.

Types of automation

Pressure adjustment

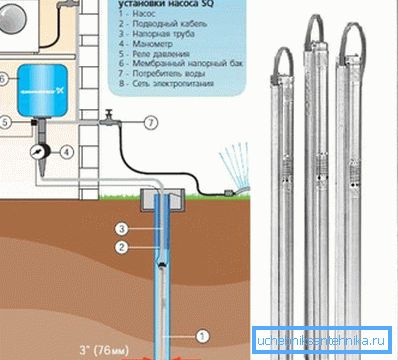

For individual wells, it is preferable to install a set of equipment that adjusts to the pressure level in the system. For this purpose, a membrane-type receiver is built into the water supply circuit, which is able to compensate for hydraulic shocks and maintain excess pressure in the pipes.

Adjustment is carried out in this way:

- The pressure switch (mounted separately or as part of an automatic pumping station) is adjusted to two indicators: the level at which the water supply is turned on, and the level at which the pump is turned off.

- To avoid switching on too often, adjustable limits are chosen according to pump performance and receiver characteristics.

- For maximum performance, industrial relays should be used (XMP from Telemecanique, MDR from Condor and similar). They withstand a significant amount of current (15-16 A) and are equipped with reliable contacts. The minus of professional relays is the absence of graduation: a pressure gauge is used for adjustment, which negatively affects the accuracy.

- Home appliances are easier to use, but less reliable. If you do not have the appropriate skill - it is better not to try to customize yourself, but leave this task to professionals.

Tip! When using household relays, experts advise using additional automatic protection installed in a separate control cabinet,

Regulation depending on the level

The control of the tank filling level is necessary if the water supply is organized using a tank in the water tower or a hydraulic accumulator in the attic.

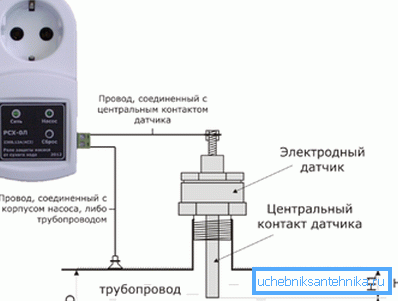

In this case, the adjustment is ensured by the functioning of a fairly simple system:

- Inside the reserve tank with water several electrodes are installed - the so-called filling sensors.

- When the water level changes, the electrodes close or open accordingly.

- As soon as the water reaches the top mark, the control relay shuts off the pump and the water supply stops.

- When reaching the lower mark, the pump is activated, resuming the water supply to the tank.

Instead of electrodes, such systems are sometimes equipped with so-called float switches. However, these devices are less reliable and have a small work reserve.

Note! In any case, the instruction recommends installing an emergency discharge system on the tank, or else install a separate alarm unit at overflow.

Adjustment systems “tied” to the water level in the tank are more often used for mass water supply. Pumps for wells with automatics of the level type last much longer, since their mode of operation is more stable. Also saving resource contributes to the lack of short-term launches.

Protective mechanisms

Another important function of the adjustment systems is to protect the mechanism itself. An automatic borehole pump is usually equipped with several safety devices, which allows it to remain in working condition even under heavy loads.

The main reasons for the breakdown of the device are:

- Increase or decrease in voltage in the network.

- The operation of an electric motor under extreme load for a long time.

- “Dry run”, i.e. functioning of the pump part without water.

Each of these reasons must be eliminated:

- To stabilize the power supply, relays are used to control the voltage. At current surges, such a device simply turns off the pump. Modern models are additionally equipped with a time delay relay, which prevents frequent switching on of the device during a series of voltage surges.

Note! In industrial water supply systems, current stabilizers can be used, but their use is rather expensive.

- So that the engine does not overheat under heavy loads, the so-called thermal current relay is used. In this case, the setting of this part is carried out so that its parameters correspond to the nominal characteristics of the pump.

- Protection against dry running is increasingly being built into the pump itself. Such an adjustment is called “indirect”: the pump shuts off when the flow part starts to idle. However, this increases the level of wear of all parts.

- More reliable is the adjustment of the device operation according to the water level in the well: as is the case with the tank, either sensors or floats can be used.

All of these mechanisms can be assembled both on the meringue of printed circuit boards and on the basis of microprocessors. Autoregulation processors are more reliable, but they are much more expensive, and they should be configured by professionals.

Conclusion

Automation of wells equipped with an electric submersible pump allows you to significantly optimize all work processes. At the same time, we will not only reduce energy costs, but also reduce the wear and tear of the water-lifting device itself. More information on this topic contains a video in this article.