Automation for the well: what elements it consists of and

When arranging water supply using underground resources, it is extremely important to choose the right automation for it.

The term "automation for wells" means a complex of devices consisting of:

- control relays;

- power electrical unit;

- various protective systems, the purpose of which is to prevent the danger of damage to the motor and the pump itself.

Automatic pump control

Most commonly used are two control schemes for starting / stopping a submersible pump:

- by the volume of water in the storage tank;

- on the level of pressure in the water supply.

Controlling water level work

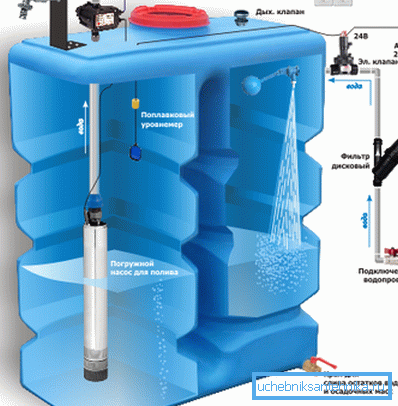

This scheme is used when operating submersible pumps for water-pressure facilities or to fill a special tank, from which water is pumped to consumers by an additional pump.

- Inside the storage tanks are mounted special level sensors. They, with the help of command relays, monitor the lower and upper filling threshold of the tank. Depending on the volume of water, the relays give commands to start or stop the pump. Sensors can be float or electrode. The first are less reliable, because their working resource is small.

- The water storage capacity must be equipped with an emergency overflow, in case it overflows.

Note! The main advantage of this scheme is the stability of the pump. Hydraulics while constant, because nominal consumption is calculated on the height consisting of the depth of the well, the height of the water tower and 1/2 meter spout. Each cycle is equal to the expenditure of the entire volume of the tank / tower, it takes into account the consumption of the current water analysis. The danger of engine twitching is prevented, this increases its service life.

Pressure control pump

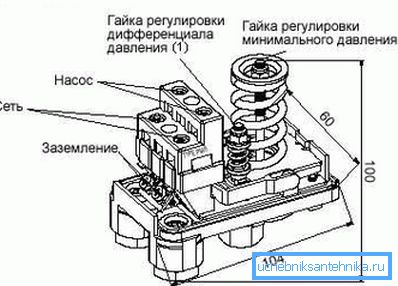

- According to this scheme, the pump is controlled by a relay command, which is mounted on the pipeline. It sets two values: the pressure at which to turn on or turn off the pump.

- This automatic water supply from a well is most often used for individual wells, in contrast to the previous scheme, typical for collective water supply systems.

- As a rule, in this case, receivers are used (membrane tanks). They are needed to keep the required overpressure in the system, as well as to compensate for low costs and water hammering.

- It is very important to correctly configure the relay, based on the parameters of the pump and the volume of the receiver. So that the pumping unit does not work too often, it is necessary to set the upper and lower pressure thresholds, based on the average zone of the pump characteristics. The hysteresis of the values must be selected from 1.2 bar to 2.5, taking into account the data on the maximum of the pump starts at a certain time.

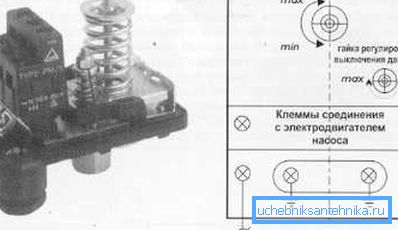

Pressure switches, which are used in such a scheme, are divided into industrial and domestic counterparts.

- The first ones are equipped with powerful contact groups and can withstand a current of up to 16 amps. However, they do not have an adjustment scale showing the pressure range for adjustment.

- Therefore, a pressure gauge is required to set up such relays.

- The advantage of such devices for the well is the possibility of use in power electrical circuits for direct control of the pump. In addition, industrial devices have high reliability and accuracy.

- Cons - low tuning accuracy and low working life, due to the impact of strong inrush currents. The devices have low-current contacts, they need to be switched via the external starter.

The instruction requires for operation of the pump, in conjunction with an industrial type of relay, to use control cabinets with instruments for additional protection or without them.

Mounting a household relay, it is enough to connect the pump directly, with the help of its contact groups, to the mains. The simple design and low price of the device make it popular among buyers.

Note! However, this savings is leveled by additional expenses associated with the replacement of the relay, which do not differ in durability. In addition, even if you put a new device with your own hands, you will hardly be able to restore its necessary settings and test the operation.

Pump protection devices

The main causes of borehole pump failures are:

- their operation at reduced / increased voltage in the power grid;

- motor overload;

- their work at idle, in other words - without water.

Security Techniques

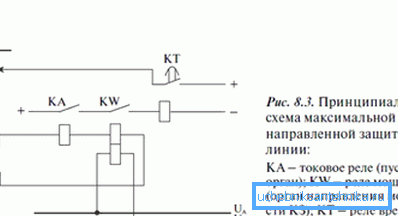

- The best way to make pump power quality is to use AC voltage stabilizers.. Often, the automatic wellbore includes a voltage control relay. It turns off the pump when the voltage drops and adjusts the asymmetry and phase sequence on three-phase motors.

- Electric motors are protected from overloads by thermal (current) relays. They turn off the unit when the set current is reached. It is important that the variation of the settings of such a relay coincides with the nominal value of the pump current.

- From idling pumps are protected by two methods. Directly - by the volume of water in the tank / tower, using electrode or float sensors. Indirectly - by the magnitude of the current or the change in the phases and voltage of the electric motor current, by means of a relay.

Minus indirect type of protection is its secondary nature. The control relay reacts only when the bearings and the flow-through unit are already left without water, which cools and lubricates them.

When the pump capacity is higher than the well flow rate, this happens several times a day. This reduces the service life of the submersible pump. Therefore, it is desirable to put an electrode device to control the volume. It makes it possible to turn off the pump before an accident occurs.

Types of protective devices

Different types and combinations of devices can be used to protect and control the pump.

They are divided into 3 categories:

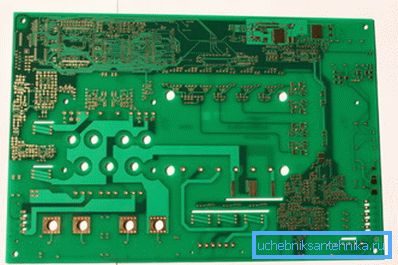

- protection devices, which are based on printed circuit boards QA-50B or QA-60C;

- relay control units;

- microprocessor based devices.

PCB-based devices are structurally and functionally complete devices.

- They require the connection of external equipment: the pump itself, often through a starter (magnetic), a pressure switch, level sensors, etc.

- They have a wide range of adjustable options and parameters: current (thermal) protection, compensation of voltage drops, idle speed control and motor loads, etc.

- It should be noted that due to the completeness of the device, it is not possible to change the logic of its operation.

- In addition, models often do not have the option of changing response values in some parameters. If the board fails, then you need to change it all. At cost, this is almost the same as buying a new device.

Relay automatics on the well is very diverse. This may be the simplest devices and cabinets in which devices are located that regulate the operation of several pumps.

The advantages of this kind of devices:

- relative reliability and simplicity of design;

- quick and easy upgrades for non-standard use;

- if any element of the device breaks, then only it changes.

Devices that regulate the operation and protection of pumps, which are based on microprocessor controllers, are the most modern and complex.

They provide an opportunity to control the following parameters of the unit operation:

- the amount of resistance to its isolation;

- motor temperature;

- sequence of alternation and phase asymmetry;

- compensate for low / high voltage;

- protect the engine from overload and idling;

- provide an opportunity to take into account the time of the device and the amount of energy consumed in this case.

Conclusion

At the moment, it is difficult to imagine the operation of both individual and collective wells without using functional and protective automation. It makes it possible to increase the efficiency of water supply and increase the durability of the equipment used in this process. Check out the published video in this article. It contains a lot of useful information.