Ball-type brass water faucet with removable fitting

The number of communication systems in modern residential buildings is very high, and some of them require the installation of water fittings. One of the important elements is a faucet that allows you to dispense the supply of fluid. Unlike a faucet, this appliance is able to supply only hot or cold water.

Pros and cons of the ball mechanism

Water taps and toilet taps, whose main component has a spherical shape, are in particular demand. Such popularity is due primarily to the numerous advantages of products. However, along with the positive aspects should be considered negative aspects.

Benefits list

- The most simple design does not imply the presence of complex parts, so the reliability of the products is very high.

- The low price of this type of water-folding products allows to significantly expand the consumer environment.

- Due to the small turning radius of the lever, an emergency closure can be made in a matter of seconds.

- When operating such cranes, you can visually determine the level of overlap of the feed channel.

- The scope of application is quite wide, which means that the product is widespread.

- The possibility of installing by hand is an additional advantage, since in this case it is possible to save financial resources.

Some disadvantages

- With a low quality of the working environment, the products can fail, especially if they have not turned for a long time.

- Prolonged exposure to rust usually causes damage to the surface of the main element, so the tap starts to pass water even in the closed position.

- It is not recommended to install this device in rooms where it is possible to lower the temperature to minus marks.

Addition! The presented products have cavities located between the body and the ball, which leads to sedimentation of solid particles in this zone. This state of affairs adversely affects the saddle rings.

Description of the principle of operation

Each ball mechanism has a special valve in the housing, in which a through hole is drilled. Its diameter corresponds to the size of the pipeline being connected, therefore, with full opening, no reduction in throughput is observed. That is, the water flows at the same rate and with the same pressure.

When opening the axis of the hole and the pipeline coincide, and after turning 90 degrees, the flow area completely overlaps. In this case, a barrier arises in the form of the side walls of the ball in the path of water movement. If the lever is rotated 45 degrees, then the flow of fluid will be carried out in a truncated mode.

As a sealing layer for the gap between the housing and the polished surface of the movable device, end rings are used, the pressing of which is ensured by special springs or coupling bolts.

Such products in living conditions can be installed for a washstand. Flow control is most often done with and using a lever.

Technical information

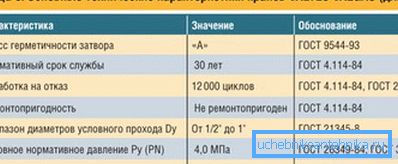

To evaluate the product, it is necessary to become familiar with the technical characteristics of one model of a popular manufacturer. Such a device is usually used as water fittings, which is installed on pipelines of hot and cold water supply networks.

As for process lines, a crane of this type can be installed on elements that carry out the transport of gases and liquids. To attach the hose has a removable fitting. All products must comply with the points set out in GOST 19681.

| Characteristic | Indicator |

| Nominal pressure | 1.6 MPa |

| Flow at low operating pressure | 0.07 l / s |

| Approximate service life | 20 years |

| Joint tightness | > 0.4 MPa |

| Average resource | 4000 cycles |

| Nominal dimensions | ? and? an inch |

| Test pressure | 2.4 MPa |

| The force applied to the lever |

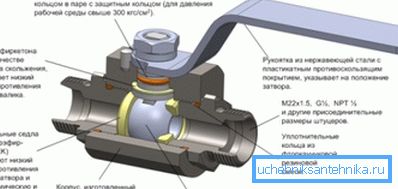

Device products

This element of water fittings usually consists of a considerable number of component parts, although it is a device that is not very complex.

The following describes the basic components that play an important role in the functioning of the product.

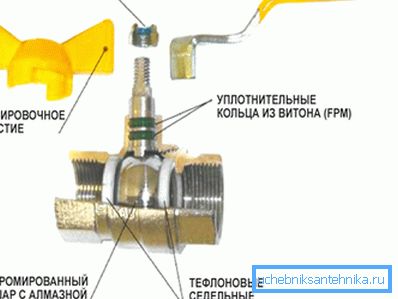

- Housing contains internal parts, protecting them from external influences. It is made of nickel-plated brass.

- Ball valve is the main element that is used to open and shut off the flow. It is made of copper alloy with chrome plating.

- Saddle rings Manufactured on the basis of Teflon, which additionally includes carbon and elastomer.

- Stock It is a kinematic element that transfers force from the drive mechanism.

- Sealing rings allow you to improve sealing. The main material is rubber.

- Anodized steel hose connector - This is a piece in the form of a sleeve, which is necessary for connection to the pipeline system.

- Cap nut refers to the elements of the threaded pipe connection for the implementation of the helical transmission.

- Silumin flap handle with fastening screw allows you to perform basic actions on the overlapping of water.

Note! Together with this product, a special ABS plastic spreader is usually supplied. The material itself is a resin resistant to mechanical damage.

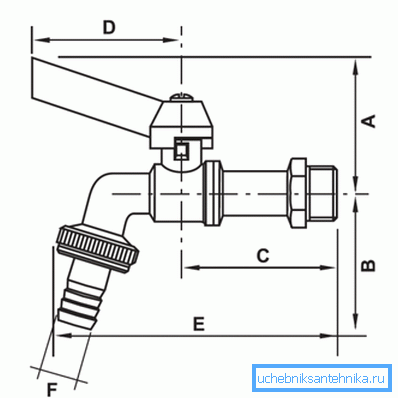

dimensions

For a better understanding of the parameters, it is proposed to take a look at a special table, in which the basic data for ball-type coupling models are given. Thread size is usually indicated by a fraction, but in this case the slash is omitted.

| Thread | Distances in millimeters | ||

| From the edge of the handle to the central axis of the valve | From the bottom of the nozzle to the central axis | From the top of the handle to the center of the channel | |

| 12 | 56 | 48 | 49 |

| 3 4 | 56 | 57 | 52 |

Installation instructions

- The coupling of the product with pipes should be carried out with the use of fluoroplastic materials for compaction in order to improve the tightness performance.

- When installing, it is not recommended to use pipe wrenches of lever type belonging to the category above the second number. The impact is allowed directly on the hexagon of the nozzle.

- Fixation of flexible hoses to fittings should be done using traditional screw clamps. The use of various types of wires in this case is not allowed.

- By installing the valve, you can not exceed the maximum possible torque. For products with thread? - 30 Nm, and for a threaded connection in increments? - 40 Nm.

Recommendations for use

- Products must be used at a certain pressure and temperature conditions. These data are usually mentioned in the description of the technical characteristics of products.

- Do not operate the device if the nut fixing the handle is in a weakened state. Otherwise the stock may fail.

Possible faults

Most often there is a leakage in the coupling, which is primarily due to poor sealing of the joint during installation work. You can fix the problem by replacing the seal, but it will have to disassemble.

Fluid leakage can also occur from under the union nut. In this case, it can be assumed that the sealing gasket is damaged. After its replacement, the product is usually functioning normally.

If it flows directly from under the stem, then with high probability we can talk about the wear of the stuffing box seal, which means that a complete replacement of the crane will be required.

Transportation and storage

- Products of this type should be stored in the packaging in which they were delivered to the consumer market. The main conditions requiring compliance are presented in paragraphs of GOST 15150.

- As for the transportation of finished products, it should be carried out in strict accordance with the same technical documentation as in the previous paragraph.

As a conclusion

Above was presented the instruction for acquaintance with the fact that such faucets for the analysis of fluid from water supply systems and other communication networks. When selling usually indicated symbols. Example: KV 15 DN15. This means that a specific type of water tap is offered with a nominal diameter of 15 mm. Other details are reflected in the video in this article.