Ball valve 3: 4 - device, characteristics, installation

Ball valves for water 3: 4 inches - the most common and high-quality type of valves used in the installation of hot and cold water pipelines, as well as heating systems. They are simple to install, reliable and compact, so today no installation can do without the use of this type of fittings.

We will talk about the device, characteristics and advantages of ball valves, as well as consider the rules for their installation.

Ball Valve Fittings

Device

A ball valve is a type of shut-off (sometimes adjusting) fittings used in pipelines of water supply, heating, gas, oil and other media pipelines. In relation to the systems of water supply and coolant, this type of fittings in most cases is used as a locking element.

It should be said that the valve with a spherical plug is a modern and quite progressive device, replacing conical models, which had many serious drawbacks associated with significant hydraulic resistance due to the shape and size of the passage.

At the same time, the construction itself was known long ago - more than 100 years ago, however, its effective implementation became possible only after the appearance of new synthetic materials, such as fluoroplast and other artificial polymers.

The valve with ball valve is quite simple.

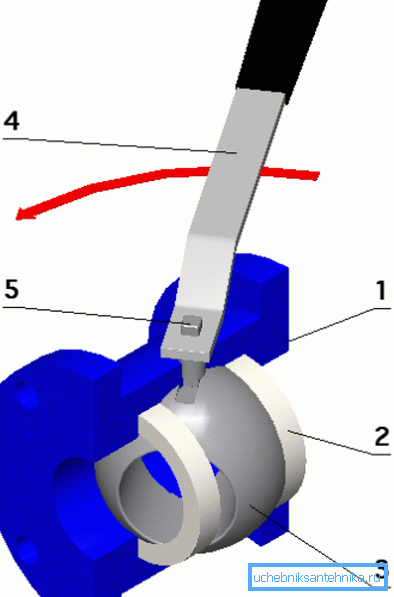

The product consists of the following elements:

- Brass body. The use of this alloy is due to the lower cost of its production, as well as a higher corrosion resistance compared to steel;

- Sealing saddles. They are used to seal the cork, made of Teflon, Teflon, polyetheretherketone (PEEK) and other synthetic polymers;

- Ball plug. Performs shutter function. The ball has an axial hole, the diameter of which coincides with the diameter of the pipe channel; when the cork is rotated 90 degrees, the channel overlaps, since the perpendicular axis of the ball has no holes;

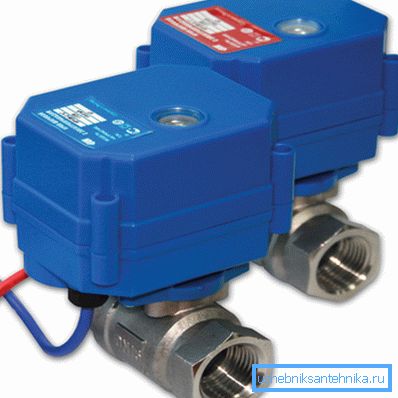

- Shutter control. It can be in the form of a lever, a butterfly, or a lamb; in addition, instead of a handle, an electric or pneumatic servo can be installed to automate the control of the system;

- Brass spindle which connects the handle or actuator to the stopper and transmits the force to turn it.

So, we see that inside the body there is a spherical shutter with a slotted through hole.

If you turn the cork so that the hole in it coincides with the flow channel, then the medium will move freely through it with minimal resistance, which will not differ significantly from the resistance in a similar pipe with the same diameter.

Then we turn the bolt 90 degrees and the ball closes the channel.

Note! As you can see, this type of valves is designed very simply, which gives high reliability and relatively low cost due to the simplicity of production of products with such a design.

Specifications

The main technical characteristics that are used to describe the features of the device and the selection of a model suitable for one purpose or another are as follows:

- Nature of work environment. Here, indicate the type of substance that can be transported through the device (water, gas, oil, etc.) and the temperature range in which its operation is possible;

- Nominal working pressure. It is denoted by the letters PN and a number that is equal to the value of the working pressure in the atmospheres. Marking example - PN 40;

- Channel diameter. It is denoted in inches or millimeters, denoted by letters DN and a number that indicates the diameter in mm, for example, DN Also can the diameter be specified in fractions of an inch, for example,?, 1/2, 1, 1? etc. There is a transition ball valve 1: 2 to 3: 4;

- The nature of the location of the thread on the inlet. There are models with internal thread on both sides, they are designated as in-in, with internal and external threads - in-n, with an external thread on both sides - nn. In addition, on the one hand the crane may be driven off with an American nut.

Determine how much the diameter of the ball valve 3: 4, will help you table matching the size of pipes:

Note! When choosing a product should pay attention to the material of which it consists. Quality models are made of pure or chrome-plated brass, sometimes from anti-corrosion steel. Silumin products can not be bought, as they are of low strength.

To distinguish silumin from brass, it is enough to take two taps in hand: brass will be noticeably heavier. In addition, silumin gets dirty, and when rubbing against a piece of light matter or fabric, a gray trace remains on it.

Note that the price of ball valves is quite democratic, so it’s worth saving on them. This is especially true of heating systems, for which it is better to choose Italian products, for example, Bugatti or Giacomini.

Installation

Installing ball valves with their own hands is not difficult.

For this we need a simple set of tools:

- Adjustable plumbing wrench;

- Dies for threading;

- Bulgarian;

- File;

- Plash holder;

- Sanitary flax and sealing paste.

It is advisable to install a strainer filter before the product (rough cleaning), since if sand or rust gets in, the surface of the plug will wear out and the tap may start to pickle the water.

This is especially important for heating systems, in which during the period of inactivity the water and the cork itself can become polluted, as a result of which the shutter will turn in great difficulty, and sometimes it will completely stop moving.

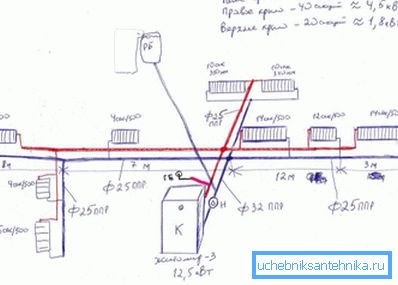

That it was more convenient for you to perceive the information, we have prepared step-by-step installation instructions:

- We perform all the necessary measurements and trim the pipe in the right place.. It is best for this to use a saber saw for a smooth cut at 90 degrees;

- We clean the end of the paint and chamfer with the cut end. This can be done with a grinder or a file. You can also use a special face picker;

- We take a die for threading the desired diameter and lubricate its teeth with lard or lube. We also lubricate the pipe itself;

- Insert the die into the die holder and cut the thread on the pipe. We should have at least 4.5 turns, but no more than 5. It is better to cut in two passes, so you will less load the pipe and the cutting tool;

- We wind on the received thread sanitary flax clockwise. Then put a good layer of sealing paste on the entire surface of the thread;

- We take the crane and wind the thread. It should be at least 4.5 revolutions. First, cheat manually, then use an adjustable wrench.

- If it is necessary to connect two fixed sections of a pipe, then we use a model with an American (with sgonom).

Note! Make sure that the thread is cut exactly. Otherwise the connection will be unreliable.

Conclusion

Ball valves are the most progressive locking devices for the installation of plumbing and heating systems. The video in this article clearly and lucidly demonstrates the process of installing such valves.