Bottom filter for the well itself

Sometimes there are cases when, after such a well-arranged device, the found water instead of becoming clean and transparent remains muddy and dirty, but this is not a reason to immediately install expensive cleaning systems. Often, you can fix the situation by installing a bottom filter for the well with your own hands.

When you need a bottom filter

The need to install a bottom filter is determined based on what kind of aquifer is represented and what is the direction of the subterranean flow. The bottom filter in the well is used to prevent silting of the well and, as a result, the formation of turbidity. But not always and not in all wells there is a need to use it, sometimes the bottom filter device can only harm the situation, blocking the flow of water, which will dramatically reduce the flow rate of the well. It is necessary to install the bottom filter in the following cases:

- when at the base of the well there is a soft and friable clay or sandy loam, which, eroding, creates turbidity during water removal;

- there is sand at the bottom of the well, and the water does not strike the well in the well, but quietly leaks out;

- a well stands on a quicksand - this is sand, oversaturated with water, which is able to liquefy when exposed to it.

Construction and type

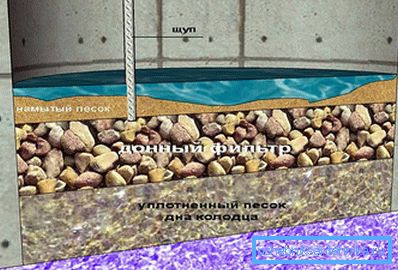

The bottom filter is a mound of layers of different fractions of gravel, sand or other mineral rocks (except granite). An excellent material for the device filter is shungite - it is petrified oil. The use of this material allows to remove heavy metals and oil products from water, and also contributes to its mineralization. In some cases, most often in floats, a wooden shield is installed at the bottom of the well. The main requirement for filter materials is their neutrality, safety for human health, they should not decompose and react with water, and the materials used in the cleaning system should not be used.

The bottom filter should consist of different fractions with a specific particle size distribution and shape. The best form for the filter is a smooth and rounded rock with a size of 30 to 80 mm. Smaller fractions with stab forms lead to compaction of the filter, and sometimes to cementation, such a filter will, on the contrary, prevent the inflow of water into the well, and it can only be removed from the well with scrap.

Before you make the bottom filter, you need to decide on its design. There are two basic filter designs - direct and reverse. The direct filter consists of two fractions, a large one, which is placed on the bottom of the well, and an upper, fine-grained one. The minimum thickness of each layer should be 15 cm. Such a filter is used when there are loams at the bottom of the well or to create a filter on the quicksand. The return filter has a design opposite to the direct filter. In the construction of such a filter, the lower layer consists of a fine fraction (coarse washed river sand), then a larger fraction, about 1 cm (pebbles, gravel or shungite), and the last layer - the largest stones larger than 5 cm. Are placed. The thickness of each layer , as in the first case, should not be less than 15 cm. Such a filter is used for wells with a sandy bottom and a smooth flow of water, it prevents sand from being raised by the action of water jets or mechanical impact.

In the well at swimmill

In the wells, which stand on the quicksand, it is practically impossible to get clean water without the use of a bottom filter, in addition to prevent the silting of the bottom filter, it should be protected with a wooden shield. The shield also helps to stop or slow down the quicksand. You can make it from the boards of different wood species, but aspen is considered the best, it also has a disinfecting effect in addition to durability.

The diameter of the shield should correspond to the inner diameter of the well, holes can be drilled in the shield, with a diameter of at least 10 mm, for better circulation of water, the boards are knocked together with two bars 5 cm thick, these bars will act as legs. Next, the finished shield is lowered to the bottom of the well, large stones of pebbles are laid on top of the shield to keep the shield from floating, the second layer is a pebble, only smaller, and a layer thickness of at least 20 cm, you can use shungite instead of pebbles. During operation of a well on a floating land one should not completely drain water from it; leave at least 20–30 cm so that this water presses on the bottom of the well. In intensive quicksand, the shield is gradually tightened with sand, so you need to install a new filter every 5–7 years.

Operation and care

During operation, the filter is clogged and silted with fine sand and clay, and therefore needs to be cleaned. To clean, remove the stones and rinse them with water, sand must be completely replaced, then everything must be put in place in the same sequence. Properly selected filter design and timely cleaning will help to get clean water and maintain a high flow rate of the well.

Video

In this video you can watch the installation of the bottom filter with schungite in the well:

We also recommend that you read the articles:

"Warming of a well for the winter".

"How to clean a well".