Centrifugal pump for a well: assistance in the selection and

How are submersible centrifugal pumps for wells? What are the characteristics of choosing such a device? Does he have any reasonable alternatives? Should I take into account any of its features when working with a pump? Let's try to answer these questions.

What it is

Let's start with a little excursion into the jungle of mechanics.

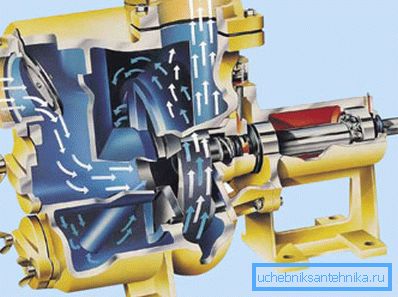

The simplest, durable and efficient pump scheme that can be used for lifting and transporting relatively clean water is a centrifugal impeller in the cochlea - the body, and in fact strongly resembling the shell of a mollusk.

How does such a device work?

- The impeller is driven by an electric motor. In this case, the blades throw water to the periphery of the cochlea, creating an overpressure at its walls. It is necessary to open the water passage - and it will rush out of the hull.

Curiously, due to the hydrodynamic features, the greatest pressure is created when the outlet nozzle is directed tangentially to the body in the direction of rotation of the impeller.

- In the area of the impeller axis, on the contrary, a vacuum will be created. For continuous operation of the pump, it is enough to organize the water supply along the axis of rotation.

The snail has one harmful feature. The capacity of the pump and the pressure at the outlet is greater, the smaller the gap between the impeller and the housing. In fact, with a large gap, part of the water chases in a circle inside the hull.

This property is the Achilles' heel of the so-called vortex pump, the scheme of which we have just exhaustively described. It is applicable only and exclusively for the transportation of clean (no more than 30 grams of impurities per cubic meter) of water.

Why?

- With a minimum gap between the impeller and the casing, measured in fractions of a millimeter, fine sand and abrasive impurities act like sandpaper. In just a few weeks of work, the cochlea wears out to a state of complete inoperability.

- As the gap increases, the pressure drops sharply at the outlet.

However, centrifugal pumps usually indicate much more democratic characteristics: the allowable size of solid particles is up to 2 millimeters, the amount of impurities is up to 150 g / m3. Due to what?

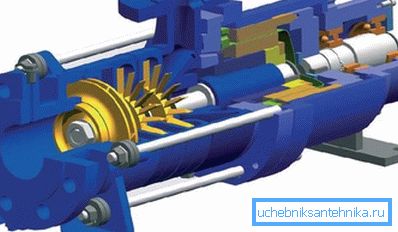

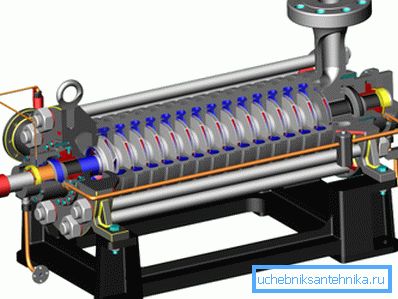

The main problem of vortex pumps is solved in centrifugal constructions simply and elegantly.

The impeller (or, as it is properly called, the impeller) is separated from the housing a few millimeters. Due to the significant gap suspended through the snail, without causing any damage to the device. The drop in pressure and performance is compensated by the presence of several stages, each of which consists of an impeller and a diffuser.

Useful: each stage of the pump raises the pressure at its output by 5-10 meters. In this case, the complexity of the design is minimal: all impellers are rotated by a single electric motor.

Help in choosing

How and by what signs to choose a centrifugal well pump?

Head pressure

This is the name of the maximum height to which a device is capable of raising a water column in the absence of a tap. How to determine what value should be oriented?

Instructions for calculating the required pressure is quite simple.

- The distance from the depth of the pump to the surface is taken as the base value. Note: not from the mirror water, it is from the pump. Given the dynamic changes in the water level, it sinks to a considerable depth.

- The resulting value is added 30 meters. Why so much?

Excessive pressure will raise the water to the second or third floor of a private house; in addition, it will ensure the normal operation of plumbing equipment. Stop valves and faucets, you know, work extremely poorly in the absence of overpressure in pipes.

- An additional 10% is added to the result for unaccounted losses. Pipes (especially steel, which have served for several years and become rough inside) have significant hydraulic resistance. The pressure is lost on the turns of the water supply system, on valves, mixers and flexible liners.

Let us, as an example, calculate the pressure on which to navigate when choosing a pump immersed in a well to a depth of ten meters.

- The base value is the same 10 meters for the surface.

- We add 30 meters necessary for normal work of sanitary equipment and raising of water to the upper floors. 10 + 30 = 40.

- An additional 10% for unaccounted losses will increase the calculated head value to 40x1.1 = 44 meters.

- Round the resulting value in a big way. Obviously, we have to look for a centrifugal pump that provides a pressure of 50 meters.

Do I need extra head margin? Not.

There are several reasons.

- The higher the stated head, the higher the price of the pump. There is a completely objective reason for this: the design becomes more complicated, additional steps are added.

- Greater pressure means energy waste. Notice, not justified.

- Finally, excess pressure in the water supply is dangerous for plumbing equipment. First of all - for plastic inlet valves in toilet bowls and flexible connections to the mixers.

Performance

Ideally, it should be greater than the flow rate (water inflow into the well from aquifers), but less than peak discharge.

By the way: in the presence of a large-capacity buffer capacity, the last item can be neglected.

How to determine the flow rate of the well and water flow?

To determine how much water enters the well per unit of time, it is sufficient to empty it to a fixed level and measure the time it takes for the water mirror to return to its previous mark. Next - simple arithmetic.

Suppose, in a well with a diameter of 1.6 meters (the standard size of reinforced concrete rings), we pumped water 2 meters from the original mark. To the previous level, she returned in 1 hour exactly.

Let's try to calculate the flow rate in liters per minute.

- The volume of water column with a diameter of 1.6 and a height of 2 meters is equal to 3.1415x (0.8) ^ 2x2 = 4.02112 m3, or approximately 4000 liters.

- Every minute 4000/60 = 67 liters of water arrive at the well.

How to assess the family’s need for water?

In order not to suffer from attempts to measure them, we give statistical data. For a family of 3-4 people should count on 40-50 liters per minute. With an increase in the number of family members, water costs increase proportionally; the need for watering the area additionally doubles them.

Dimensions and manufacturer

If a submersible pump for a well is limited by the diameter of the casing, then in the case of a well in terms of dimensions, there is complete freedom. The larger the diameter, the cheaper the device with the same characteristics: with an increase in the diameter of the motor and impellers, it is possible to provide performance and torque with far less resources. In particular, the motor winding is simplified and the number of impellers decreases.

Which manufacturer should choose?

There are only two important factors:

- Cost of. If, in the case of a downhole pump, saving may be sideways, since raising a failed device is not a trivial task, then it is perfectly acceptable not to chase brands.

- Location of service centers. If the service authorized by Vodomet’s products is near you and the Grundfos service is in the neighboring town, the choice is obvious.

Tip: The float switch is a very useful addition. It will stop the motor at a critical drop in the water level in the well.

Alternatives

Is a centrifugal pump always the best choice for a well? The answer is ambiguous.

On the one hand, the centrifugal scheme combines excellent performance with unpretentiousness and great resource. On the other hand, alternative solutions have quite tangible advantages.

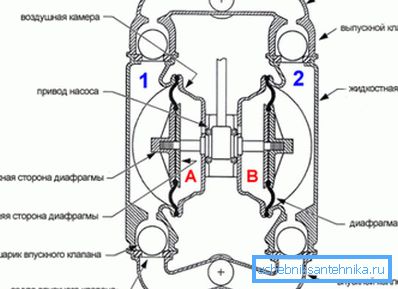

Diaphragm pump

It is a design of a solenoid with one or two diaphragms and check valves. Several times a second, power is supplied to the solenoid, and the membrane attached to its core pushes water from the working chamber into the feed pipe. The return stroke of the core is provided by a spring or an additional electrical circuit.

The main value of the membrane scheme - the marginal cheapness, which directly follows from the simplicity of the design.

In wells, diaphragm pumps are quite low in popularity due to two features:

- The vibration generated by the solenoid is destructive to the walls of the well. It greatly accelerates the silting of the trunk.

- Since the membranes are deformed during the operation of the device, its overhaul life is limited to one to two years. Replacing the membranes is a fairly simple operation, but lifting the well pump is not very.

However, the use in the well, obviously, allows to neglect both drawbacks of the circuit.

Surface pump

As the name implies, this device is mounted on a surface; a rigid hose or pipe is lowered to raise the water in the well.

What gives such an arrangement?

- Problems with a waterproofing of the motor are completely eliminated. Water simply does not contact with it: the electric motor and the snail are spaced apart in space, only the shaft connects them.

- Repair and maintenance are greatly simplified because they do not require lifting equipment.

- The lack of pressure due to a sufficiently large gap between the impeller and the body of the cochlea can be compensated by simply increasing their linear dimensions, which in this case are practically unlimited.

The downside of the location of the pumping station above the water level is that the depth at which this water can rise is limited to seven to eight meters. With a greater differential motor just idling.

However: for small pumps a curious modification is often used. They are installed on the frame, attached to the island floating in the well. Buoyancy is ensured by thick foam; the size of the island, almost equal to the area of the water mirror, does not allow the structure to roll over.

Features of operation

What should I pay attention to, by connecting the centrifugal pump with the water supply system with my own hands?

- The best cables are made of stainless steel. They have tensile strengths up to a ton; more than that: this strength does not decrease with time due to corrosion.

- The pump falls and rises strictly for the cable. The power cable and the pressure pipe or hose are selected to the rope with plastic clips.

- Immediately after the outlet is put a check valve. Otherwise, the water from the water supply system after the power is turned off will merge into the well.

- If the pump is used not only for irrigation, but also for water supply at home, the hydroaccumulator and pressure sensor are included in its piping. In this case, the power will be supplied to the motor only when the pressure in the system drops to a critical value.

Plan B: a storage tank may be included in the water supply system. It is installed at the top of the water supply system and is completed with the simplest float level sensor.

Conclusion

If some points were unclear to the reader, he may find the answers by viewing the video in this article. Successes!