Centrifugal pumps for wells: the history of the invention

The question of how to provide your suburban housing with autonomous water supply is relevant today for many homeowners. No one wants to carry water in buckets from wells. The yoke can be seen only in drawings or in museums.

The buckets were replaced by pumps that pump water into the piping system on their own. The main thing is to make the right choice when equipping the well with a lifting mechanism.

Types of pumps

Any pumps that are used to lift water from wells are divided into two types according to the place of their installation.

They can be:

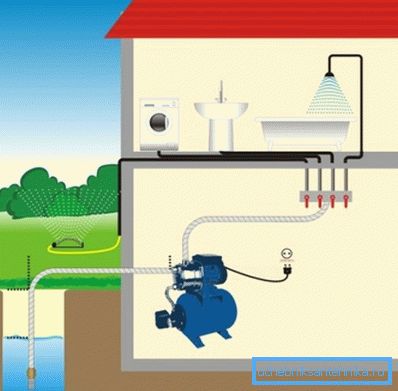

- superficial, when the casing is located near the well or with the help of a float it keeps on the surface of the water, and pumps water from the depth of the well;

- submersible, when the unit itself is at a depth and supplies water through the hoses to the surface.

The most common in everyday life types of these units are surface devices.

They are used quite widely:

- for raising drinking water from wells;

- for raising drinking water from a well;

- for pumping water from flooded basements;

- for irrigation water pumped from reservoirs.

The disadvantage of these mechanisms is that they can take water from a depth of no more than 8 meters. Accordingly, to apply them to deep wells with drinking water will not work.

Submersible pumping equipment suitable for pumping water from wells is capable of pumping water from a considerable depth. Submersible units are distinguished by the mechanism of swinging water.

They are of three types:

- vortex, in which the pumping of water occurs due to the formation of a vortex flow, they have an impeller in the form of a flat disk with short blades;

- centrifugal, pumping is due to centrifugal force, which creates a shaft with propeller blades located on it;

- vibration, in which the pumping occurs due to the difference in the resulting pressure on different sides of the membrane, which is the main structural detail.

The choice of the required type of unit is carried out on the basis of the following parameters:

- total depth of the well and the water level in it;

- total water demand;

- the actual indicators of the estimated water pressure in the alignment;

- the diameter of the pillar range.

The most common today are centrifugal models of submersible-type pumps for lifting water from wells. They provide sufficient performance and can even work with water containing sand impurities.

Centrifugal force application

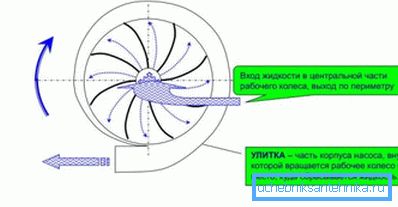

Pumps, whose action is based on the use of centrifugal force for lifting water, are widely used in our time. A centrifugal submersible pump for a well pumps water through the rotation of a special wheel, which is attached to the shaft.

A bit of history

It is very difficult now to determine who invented the first to use centrifugal force to lift water. There are famous sketches that were made by Leonardo da Vinci. According to them, it is quite possible to assume that it was he who first proposed to pump water through the use of centrifugal force in a rotating channel.

In practice, the first known device was tested in 1732. It was developed by LeDemur.

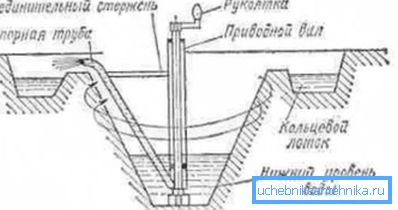

The essence of this pump was as follows:

- a pipe was attached to the vertical shaft, rigidly tied to it with a connecting rod;

- the lower end of the pipe was immersed in water;

- the shaft began to rotate, the pipe was also rotated;

- centrifugal forces caused the movement of water in the pipe.

But centrifugal pumps became common only from the end of the 19th century. At this time, thermal, and then electric motors appeared, which made it possible to create even multi-stage units for deep wells.

Russian engineer V.A. Pushechnikov developed a multistage pump based on the application of centrifugal force for wells up to 250 m depth.

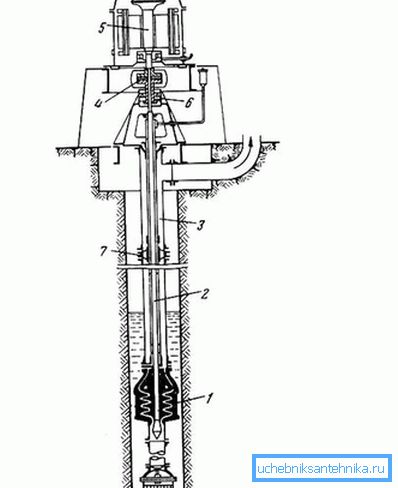

The principle of the device can be described as follows:

- the elastic coupling serves as the connection of the drive shaft with the electric motor;

- the oil bath is directly below the coupling;

- a ball bearing is placed in the bath, which takes up the axial load;

- oil for lubrication is supplied through a string of pipes suspended from the support frame;

- the column and the drive shaft are supported on bearings, which are placed in cross-shaped brackets;

- brackets are installed between the pipe joints;

- in the support frame itself there is a stuffing box, under it there is a branch pipe for injection pipes;

- the suction fitting of the pump is connected to the suction pipe, there is a safety net on the pipe.

This design facilitates the placement of the pump in a well of not very large diameter. The very first pump of this design was manufactured at the end of 1899. And it was installed on a pumping station in Mytishchi.

The tests were successful, soon there were manufactured such downhole centrifugal pumps in the amount of 19 pieces, which were also installed on this pumping station.

It is interesting that they were able to fulfill this order for the manufacture of units only in Paris at the Farko plant, although a proposal to place an order was sent to 24 plants in different countries. In the technical literature can be found the name of this pump, as the "pump Farka", and not by the name of the designer. (See also the article Which Pump is Better for a Well: Selection Parameters.)

The principle of operation of modern models

When deciding how to choose a centrifugal pump for a well, it is necessary to understand the basic parameters by which the models differ.

Various centrifugal pumps for a well can be classified as follows:

- according to the number of wheels available, if one wheel, then the devices are single-stage, if more, then multistage;

- on a pressure, from a low or average pressure to high values;

- by way of water supply, one-way or two-sided;

- the method used to drain fluid into the spiral channel from the impeller can be spiral and turbine;

- on speed, low-speed, normal, high-speed.

Important. Despite the fact that the price of multi-stage models is more expensive than single-stage models, many prefer to install them. The fact is that such models have a greater margin of safety and do not deteriorate due to the content in the water of various impurities of mechanical order.

The principle of operation of these mechanisms is as follows:

- water is supplied, due to the rapid rotation of the impeller creates an abundant flow;

- centrifugal force acts by displacing water from wheel centers to distant sites;

- pressure inside increases, it displaces fluid into the pipeline;

- the pressure in the center of the impeller decreases accordingly;

- water flows back through the suction pipe.

Deep well pump looks like a cylinder. This allows you to place it in fairly narrow wells. The length of the structure can be from 0.5 to 2.5 meters, and the diameter is approximately 10 cm. Despite its modest dimensions, these devices for wells are characterized by excellent performance.

Important. You must ensure that the pump during operation does not touch the walls of the wellbore. If the diameter of the valve is too small, it is necessary to protect the unit by putting a rubber ring on its body.

The installation of a centrifugal pump in the well is carried out by specialists, as it is very important to do everything correctly if you want to use the water from the well for a long time without knowing the worries.

The unit is lowered into the well to a depth, having previously secured it with a safety cable to the tip or lid of the well. The electric cable is connected to the pump and is also passed through a special hole in the tip.

The pump must be connected to the pipe with a brass fitting. The second end of this pipe is connected to the outlet on the cap.

If you have experience in the installation business, you can do it yourself to connect the centrifugal pump to the well. The main thing is to comply with all the requirements that describes the instructions for a particular model.

Important. When installing equipment in a well at a depth greater than 80 meters, a pipe is used that can withstand a pressure of 16 atmospheres. With a smaller installation depth, it is enough to use a pipe at 12.5 atmospheres.

Summary

Properly selected pumping equipment will ensure the operation of the water supply system in an uninterrupted mode. In the presented video in this article you will find additional information on this topic.