Choosing the best stopcock

When installing water and heating in the house, proper design and installation of pipes is only half the battle. The durability and reliability of the system depends largely on the selected valves. Spherical cranes are quite popular, the stopcock for water of this type is distinguished by high durability and excellent performance properties.

A bit of history

The very idea of regulating the movement of water flow by blocking (full or partial) pipe originated before our era - in ancient Rome. True, then for this purpose, ordinary copper plates were used, and the process itself had little in common with modern valves.

A stopcock with a locking part, made in the form of a ball, appeared much later. But such devices were not widely used for one reason only - there were no materials for the sealing seat under the ball that would last long enough. In addition to the impact of a liquid, such a material must also withstand a mechanical impact from a rotating ball.

Nevertheless, the prototype of the modern locking device can be seen in the usual Russian samovar - the locking part of the crane of Russian samovars uses exactly the same principle. The only difference is in the form of the locking part - in samovars it looks like a cone with a hole.

The official beginning of the use of ball valves in human economic activity can be considered the year 1954, it was then that Howard Freeman patented the use of such a device in an airplane on the fuel system pipe.

In fairness, it is worth noting that he was just the first person who came up with the idea to patent such a device, the identity of the person who first came up with the locking part in the form of a ball is impossible to establish.

Modern cranes of this type are slightly more complicated in construction than the locking part of a samovar crane. In modern devices, the focus is on the durability of the gasket, as well as the smoothness of the surface of the ball itself - this is necessary to minimize friction.

Everything you need to know about the stopcock

Any ball valve is a fairly simple but effective device. Such valves and fittings can be used not only in the house, but also in industry, and the design does not undergo any special changes.

The strengths and weaknesses of the ball valve

The use of this type has several advantages:

- the design allows you to instantly open / close it;

Note! In order to open the shut-off ball valve, simply turn the handle 90 ?, in the case of the valve, you need to make several turns of the valve. In industry, the ability to close the pipeline almost instantly is especially important.

- due to the simple design, there is practically no pressure loss in the pipe;

- low cost, any valves - valves, valves of this type, will cost a bit;

- maintainability;

- low weight and size;

- possibility of use in harsh operating conditions.

With regard to weaknesses, it can be noted except that the likelihood of hydraulic shock in the system. A similar effect is possible if all consumers close the taps at the same time, in which case the pipe will be seriously tested.

Note! Cone locking devices are very dependent on the quality of the fit of the cone.

In the case of the use of such devices in the industry to the weak side can be attributed to the need to install a fairly expensive electric drive. With manual control, the handle may be too long, and it may not always be possible to install it.

Classification

You can bring the separation of such devices into groups according to several parameters.

So, according to the installation method, you can select:

- clutch valves - a threaded connection with a pipeline is used, such devices are installed in houses on hot and cold water pipes, as well as heating systems. Install it yourself is not difficult;

- flange - such models can be met in the industry, differ in increased weight in comparison with muftovy;

- combined type - on the one hand flange, on the other - threaded connection;

- permanent connection (welded) is used very rarely, the pipe section on which the valve is located, is simply welded to the pipeline.

There are differences in the design of shut-off valves:

- the models with 1 inlet and outlet are called throughpipes, the stopcock through valve allows only to regulate the flow of fluid in the pipe;

- corner cranes also have 1 input and output, but at the expense of the design can be installed directly at the place of rotation of the pipeline;

- Much more functionality for cranes with more than one tap or pipe. They can be used to mix or separate the flow of liquids. This is exactly the principle that a sink ball mixer does.

The locking element can be performed not only in the form of a ball, but also in the form of a cone. The principle of operation is similar to the ball.

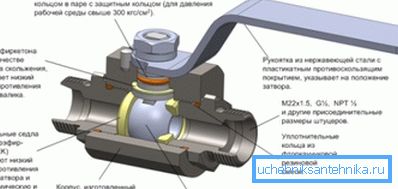

The device and principle of operation of the stopcock

The main element of any stopcock is a ball with cut-off segments, mounted in a sealing seat. In the center of the ball is a hole whose diameter depends on the internal diameter of the pipeline. The metal rod is connected to the ball, to which the handle is attached - the price of this design is minimal, and the efficiency is at its height.

Note! Small models use so-called. floating ball, in large-sized, it can be installed on special supports. In more expensive versions, the sealing gasket is spring-loaded to compensate for wear during operation.

Such a device of the stopcock allows, if necessary, to completely block the pipe with one hand movement. Turning the handle turns the ball in the saddle, completely blocking the passage.

Cone analogs work exactly according to the same principle, the only difference is the scope of application. If the ball can be considered as universal devices that can be used both in everyday life and in industry, then the conical ones are more commonly used in homes.

Note! The surface of the cone with a lack of lubrication can “stick” to the inner surface of the housing.

Selection and installation of a crane

Even at the selection stage, you can reject low-quality shut-off valves, you just need to follow these tips:

- inspect the ball valve - flows, microcracks are unacceptable, the surface should be perfectly smooth;

- check the metal from which the faucet is made, if the documentation states that it is brass, but the magnet sticks to it, then, most likely, it is a fake;

- Ideally, of course, you also need to check the thickness of the walls, but this cannot be done in the store, so the first two points will suffice.

As for the installation process, it is no more difficult than a conventional pipe joint.

The instruction is as follows:

- Linen underwrap or FUM tape is wound onto the threaded part;

Note! The direction of winding - along the thread. If the thread on the valve is internal, then the winding is performed on the pipe.

- the crane is wound, 1-2 turns manually, then with a torque wrench;

- After that, it remains only to check the tightness of the joints, if necessary, disassemble the connections and add under-windings.

Summarizing

The stopcock is simply an indispensable thing in the household. Despite the fact that its design has not significantly changed in the years that have passed since the invention, it has not affected the effectiveness in any way. The proposed material will allow the inexperienced reader to understand how the similar device works and how it works.

The video in this article shows the principle of operation of the polypropylene ball valve.