Cleaning, repair and restoration of wells in a suburban area

First of all, it should be borne in mind that there are two types of wells - sand and artesian - they differ in depth of drilling and use of the aquifer. Due to the fact that the production pipe is narrow enough in one case and in another, it is difficult to clean them, which eventually leads to silting, reduction in productivity, and even complete neglect.

Nevertheless, such objects are subject to cleaning and restoration, as we will discuss below, and in addition, we will watch the thematic video in this article as additional material.

The need for resuscitation wells

Signs and causes of destabilization

- In order to determine the unsuitability of drinking water in a well, it is often not at all necessary to carry out laboratory chemical analysis — it is enough just to look at its color and taste, and sometimes even smell. The first thing that people usually pay attention to is a change in color — the liquid becomes turbid, and sometimes (with an increased content of trivalent iron) red, but this is only the reason for installing one or another type of filter. Also, water can get an unpleasant odor - most often you also need a certain type of filter, and you can not even undertake cleaning work for the well.

- The situation is much worse when the flow rate of the well goes down - this directly indicates that it is time to clean the production pipe. In such situations, four basic methods are usually used, allowing work to be done at different speeds and efficiencies, but more on that later. It is much more difficult to produce such resuscitation when the well is full, that is, it does not bark at all or when the pipes become unusable (rusting) and have to be changed.

- And what can cause the destabilization of the well, if it is constantly looked after, that is, cleaned and used various filters to clean the contents?

Here, at least, there are three main reasons for the occurrence of which the source becomes unusable.

- Worn (rusted) pipes;

- Violation of tightness at the joints (rusted nipple coupling);

- Changes in the location of the aquifer.

- Depending on the reason or their combination, one or another type of reanimation will be used, this or that equipment will be used, and, of course, the price of work will depend on it. In such cases, it may be necessary to clean the well, replace the submersible pump, or even replace the entire production pipe. In exceptional cases (change in the aquifer), drilling of a new well may be necessary.

Cleaning work

To clean the production pipe from the surface, you need a powerful pump and a long hose that is lowered into the production pipe to the filtration zone.

Water is pumped into it under pressure, and the jet erodes silt or sand formations, throwing them upward by the resulting water column. The method is quite simple and effective, but has significant drawbacks.

To carry out cleaning by this method, it is necessary to involve hydrogeologists, so that they can calculate the head power in accordance with the strength of the filtration zone.

But here there is one unpleasant nuance - with long-term use of the well in the water, such a filter weakens, so you have to lower the jet power. The problem is that the pressure may not be enough to wash out unnecessary formations.

There is another rather unpleasant factor - the release of water in this case will be completely uncontrollable, so an area of several tens of square meters will be contaminated with silt and / or sand. To avoid such pollution, lawns and beds are covered with greenhouse cellophane film or burlap pieces, if available.

Note. For such a method, a large amount of water is required, and it is extremely difficult to prepare it in advance, since this requires a very large capacity. Therefore, the best option would be to attract a sewage truck if it has access to the well.

This method is very similar to the flushing method described above, but there is one advantage here - you don’t need to pre-prepare water, which means you don’t need a large tank or a sewage truck. The compressor along with all the equipment used for this purpose is called an airlift and delivers air at a pressure of 10-15 atmospheres.

Dirty water here is also thrown up under pressure, that is, the flow is not controlled, so the surrounding area is best covered with something, but the dirty liquid here will be less, therefore, there will be less contaminated area. This method is applied at a depth of up to 40m, which means it will be sand (not artesian) wells.

The air pressure here is much higher than the pressure of the water used in the first method, which means that the danger of filter destruction significantly increases.

We should not forget that the filter in the production pipe cannot be restored, and this means that if it is destroyed, it will be necessary to drill a new well. If there is a possibility of such damage, then you better pay attention to other cleaning methods.

This is the easiest way to clean, although long enough, but, nevertheless, it is very effective. Here you will need two pumps - one submersible, which, in fact, you use during the operation of the source, and the other - supplying water for loosening silt and / or sand formations (usually the motor pump is used for this).

Capacity is set on the surface (approximately 200m3 in volume) and is filled with water in advance. At the top, at the inlet, a filter is installed (a bucket, where a nylon stocking or a fine mesh is fitted instead of the bottom), and at the bottom an outlet is made, from where the pump will pump water.

Of course, the filter will have to be constantly cleaned, and the whole process will take a lot of time, but this method will allow you to do all the work without polluting the surrounding area.

The feed hose from the pump down to the bottom of the well (until you feel the emphasis), and then raise about 10 cm from the bottom. You need to be sure to follow the pump down pipe from the pump - if the liquid is too dirty, then it needs to be lifted a few centimeters. This process will continue until silt or sand remains at the bottom of the bucket.

Note. Since you will need to use a submersible pump for pumping, cut a water intake pipe (usually polyethylene 32 mm in diameter) in the caisson (pit), screw the inlet fitting on it and add the desired piece. After cleaning, you just as easily connect the cut place.

The most effective, although the most time-consuming method can be called a manual method of cleaning with the help of zhelonka. Such a device, which, moreover, can be made independently, allows cleaning not only silt with sand, but also small pebbles that litter the aquifer.

Such a device is a pipe with a valve and an air chamber — when the valve is lifted, silt, sand and broken rocks are drawn into the chamber. After that, the valve is lowered, and the unit, together with the contents, rises upward with the help of a cable, on which it actually holds. The valve can serve as a metal plate, as is done in the shell in the photo above, or a metal ball.

As we have said, this process is quite long and, depending on the degree of contamination of the well, can take from 4 to 8 hours. But it is completely controlled, after it there is no contaminated area and the quality of cleaning is the most excellent.

Dismantle and installation of operational pipe

Of course, the most unpleasant will be the need to replace the production pipe, but, as it were, if such a need arose, then it must be implemented and we will now find out how to do it at the lowest cost.

Drilling in itself is quite a laborious process, but dismantling is perhaps even more difficult; nevertheless, such work is quite accessible to the average man in the street (not a specialist), therefore we read and look further.

If two pipes were installed during drilling after sinking, that is, casing (external) and operational (internal), then you are unusually lucky, because you only need to change one of them, operational, keeping the walls of the well intact. But such an arrangement, unfortunately, is not always met (not for meanness, but for economy), so you have to come to terms with it.

Note. If the production pipe of the existing well is wide enough, then it can be used as casing. That is, so you will get rid of the need to pull out the old pipe to install a new one, which will significantly save both labor and financial resources.

We can say at once that if asbestos cement was used as a production pipe (production material), which was quite often done before, then this kind of dismantling is doomed to failure — asbestos cement will collapse under the exerted load, and all the work here is useless. As a rule, only metal-roll is pulled out, as the most durable, even with its partial destruction.

In order to grip, in any case, you need a metal cable, which can be fixed as a loop stitch, or you can wear a collar, to which you also attach the cable in any way convenient for you.

When choosing a lifting mechanism, any instruction is missing and for this you can use a lifting truck crane, a pulley attachment or a powerful railway jack - the main thing is to ensure sufficient lifting force.

Of course, if you have never encountered such work, it would be most reasonable to turn to professional drillers, who use special equipment for this purpose such as taps, pipeheads, events, and so on.

You can also listen to their recommendations, if they advise you to drill a new well - it can save you a lot of time, nerves and material resources.

Once you dismantle the old pipe, do not replace it with asbestos-cement - this is not only impractical, but also not recommended by WHO (World Health Organization).

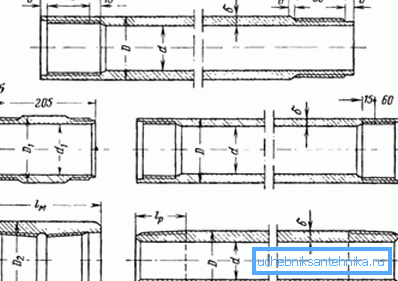

At your service there is metal and plastic, and steel pipes can have a nipple connection, or a standard one - threaded (at one end external thread, and at the other - internal). They are made of marked steel with strength groups C, D, K, E, L, M and R (GOST 632-80 (OKP 13-2100)).

If the diameter of the casing is from 114 to 168 mm, then the threaded cone should be 1/32, well, and in cases where the section is larger, this parameter decreases exactly twice and is 1/16. Couplings and nipples have identical threads and are coated with zinc or paint to protect against corrosion during storage and transportation.

Recently, for such purposes, plastic pipes are increasingly being used, where PVC is used for manufacturing, polypropylene, polyethylene, and fiberglass. Such pipes, as a rule, have a non-joint connection.

Conclusion

As you can see from the article material, restoring a well with your own hands is quite possible, but not in all cases. You may not be able to pull out an old pipe, if the need arises and here, of course, you will need the services of specialists with their equipment.