Concrete rings for wells - all you need to know about these

Well concrete rings for several decades have been used for a wide range of objects. Therefore, it is not surprising that the vast majority of wells in our country are made from such rings, these elements have a lot of advantages, which determined their popularity.

Many believe that all the rings are the same, in fact it is not, in this article we will look at how these elements differ, and how to choose the best option.

The main advantages and disadvantages of this type of structure

The popularity of concrete products is due to a number of factors that have caused such widespread use in various fields:

- Versatility - the most diverse sizes of concrete rings for wells allow you to choose the best option for solving any task - be it a well of great depth, a serious sewer or a mine in the ground.

- Price - the cost of a concrete ring for a well is much lower than any other option, this solution simply has no analogues.

- Production material - high-quality concrete brand M200, which has the highest durability and will serve you for decades.

- The reinforcement belt inside the ring gives it the highest indicators of strength - the well is resistant to the deformation effect of the soil and perfectly tolerates temperature drops.

- Concrete rings are applicable to all types of soil, they are resistant to a wide variety of adverse effects and serve equally well in almost all conditions.

- Another important aspect is the inertness of concrete, which guarantees the absence of any impact on the quality of water at the source. This distinguishes it from most materials.

- The surface of the well is strong enough, it is convenient to clean, which helps to maintain water intake in optimal condition.

- The ends of the rings for wells are equipped with a special system of grooves (the so-called locks), which allows the structure to be very firmly and securely connected without any effort on your part. Such a system greatly simplifies installation work.

There are similar products and some disadvantages.

It is worth noting that they are few, but for completeness, it is still necessary to touch:

- The large weight of each element, as is well known, the dimensions of the concrete ring for the well are impressive enough, and the material used is heavy. Such parts weigh at least 250 kilograms, and sometimes even half a ton or a ton.

- Due to the large mass, self-assembly is not possible. You will need at least a few assistants or the use of special equipment - cranes or lifts. It can be said that this is one of the biggest inconveniences.

- The diameter of the concrete rings for wells, together with its mass, also creates difficulties for loading and unloading and transportation. Therefore, the cost of transportation is also quite significant.

Features of selection and installation

Before ordering these or other elements, it is necessary to think over the plan of all actions. This will avoid unnecessary costs and provide for all the nuances that may arise during the work.

Determining the size and number of items

In order to choose the best option and calculate the required amount, you need to do the following work:

- Ask your neighbors what the depth of the aquifer is in your neighborhood. If there are no wells in the neighborhood, you can contact the competent organization that has this data. This indicator is necessary to determine the number of rings for the source.

- Further it is necessary to find out in several organizations how much concrete rings for a well cost. Very often, prices can vary in a large range, and you can save money by making just a few calls.

- The quality factor is also important, the concrete grade should be at least M200, steam treatment is also desirable. Most often, the manufacturer has documents confirming the quality, so problems should not arise.

- The dimensions of the concrete ring for the well should be selected wisely - the larger the diameter, the lower the water level will be, so you should not buy too large elements.

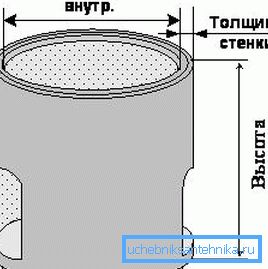

Note! Well rings are marked with letters КС and digital symbols, for example КС 10-9, it is very easy to understand the marking: the first number always indicates the internal diameter in decimeters, and the second height of the element in decimeters. Another indicator that should be clarified - the thickness of the walls.

- You should also consider how the rings will fall into the well, otherwise you risk to stop in the process of work.

Tip! You can make the lifting mechanism yourself, for this you will need 3 pipes or 3 powerful wooden bars and either a manual or electric winch. This simple device will greatly facilitate your work.

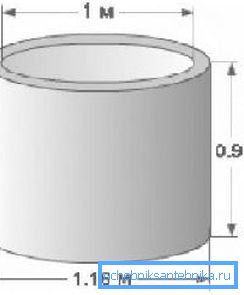

The optimum diameter of the concrete ring for the well is 1 meter, this size is most often used for the installation of water intakes. Too large diameter will reduce the water level, and too small will be inconvenient during operation.

The height of the elements, another important size of the concrete ring for the well. It is better to choose the indicator in the region of 90 centimeters, this is the best option, since the well column will be strong with a small number of connections.

The basic rules for mounting structures

Instructions for installing concrete rings with your own hands is quite simple, however, there are nuances that in no case should not be overlooked:

- First of all, you should decide on the place of digging a well; it should be removed from sources of pollution and other potentially dangerous objects. Rings should be unloaded near the site of work.

- Next, you need to decide on the method of work - it can be digging up the mine and the subsequent lowering of the elements or the method of installing the ring with a special shoe and digging up the soil inside. As the soil is removed, the ring will fall, then a new one should be substituted, and so on until the aquifer is reached.

- If water starts to appear in the mine, it should be pumped out with a pump before the work is completed. The electric light bulb does not hurt either, since it is dark enough at great depths.

- Equip a lift or draw a crane, because the weight of the concrete ring for the well is large enough.

- Joints can be further processed with special compounds.

This is the general plan for the installation of the well. In principle, based on the above information, you can easily cope with the choice of the best option for your water intake. Many are interested in how much a concrete ring for a well costs? In different regions, the price may vary, but the average varies from 1,500 to 2,500 thousand rubles. (See also the article Well or well: what to choose.)

Conclusion

You should not get the first concrete rings, sometimes unscrupulous sellers can sell homemade items, the strength of which is much lower than that of factory products. The video in this article will help to understand some of the points concerning this issue even better.