Concrete well: design features and installation description

Concreting today is widely used in all construction works. An exception was the creation of wells. In this article we will look at how to make a monolithic concrete well with your own hands.

General provisions

What may need a well in its own area?

To perform the following functions:

- Extraction of groundwater. Own plumbing system will allow full watering of crops, ensure the functioning of all the plumbing in the house and provide enough drinking water for domestic consumption.

- For filtering or stockpiling. The sewage system is also a very important element of the arrangement of any housing. If you do not control human waste, the consequences can be very deplorable. Specially equipped wells help solve this problem.

In both cases, the material of the wells is immersed under the ground and constantly in contact with the liquid.

In such aggressive conditions it is difficult to come up with something better than concrete, which has the following characteristics:

- High strength and reliability.

- Long service life. There is no susceptibility to rotting and corrosion.

- Moisture resistance.

- Affordable price.

- Simple installation technology that allows you to do it yourself.

Installation

Sealing concrete wells is of the highest quality in the case of monolithic walling. Water and sewage structures have both similar and different design solutions, consider them all step by step.

Installation Instructions:

Location selection

In both cases, the lowest point on the site is preferred.

But:

- For water, the place should be removed from the sources of possible pollution at 20-25 m.

- For drains, it is necessary to respect the distance to the residential building at least five meters.

Tip: it is recommended to place the concrete wells for sewage in such a way that the sewer does not have to be wrapped when laying out of the house. Because the places of turns are easily clogged in consequence.

Excavation

Dimensions should be chosen convenient first for installation work. That it was convenient to dig, and in the future to install the formwork with reinforcement. A square with a side of 1.2 m is suitable.

But the depth is already required different:

- In order to reach a suitable water, it is necessary to sink below the upper layer to the groundwater deposits. This can be 10-15 m.

- The filtering structure, on the contrary, must be at least one meter higher than underground sources. A depth of 2.5 m is usually used.

Bottom

Here the differences happen a little differently:

- For water and filtration wells creates a bottom filter. For this, a half-meter layer of rubble is poured down to the bottom.

Advice: in a sewage structure it is recommended to lay a wooden pallet under the inlet pipe. This will make it possible to distribute the sewage more evenly and protect the layer of gravel from leaching.

- In the cumulative version, the contents should not penetrate the ground, and therefore the concreting of the bottom of the well occurs. To do this, we first pour 15 cm of gravel, and above we pour a thin layer of cement-sand mixture.

Walls

This process is the same for all types of wells.

The difference is only in the height of the walls themselves, but the technology of their filling is identical:

- We install internal and external formwork from wooden boards. It is much easier to lay out square boards than a circle, this explains the choice of the form. A suitable distance between the formwork is 15 cm. This allows you to calculate the volume of concrete for the elements of wells: multiply the height of the pit by the sum of the lengths of the sides and the thickness of the future walls. If we have a well height of 2.5 m, then it turns out 2.5 m? 4.8 m? 0.15 m = 1.8 m3 concrete.

- We mount reinforced rods vertically and horizontally between wooden shields, connecting them with soft wire. They will betray the necessary strength to the structure.

- Create a solution. To do this, mix cement brand M 400, washed gravel and river sand in proportions 1: 5: 2.5 with water.

Tip: it is recommended to knead using a construction mixer or a drill at low revs. This is the only way to achieve the desired uniformity.

- Fill the concrete.

- If the depth is large enough, we proceed as follows:

- We dig a hole 2 m deep.

- We draw walls half a meter higher than the ground level.

- Deepen another half a meter.

- We select the ground from under the walls, leaving it in the corners to support the structure.

- We put props and finally clean the soil.

- Beat out struts and lower the structure.

- Then we increase, and then we lower it again, until we reach the required depth.

- We cover with polyethylene film and wait for full cure for 28 days, regularly pouring water.

Cumulative and water wells outside are equipped with a clay castle 50 cm thick, and the filtering well - rubble.

Cap

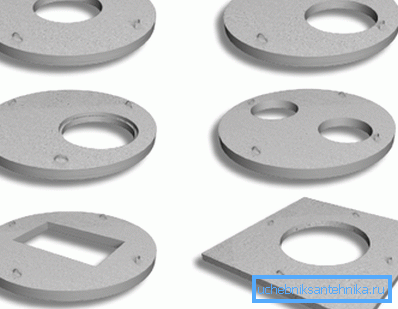

- Drainage structures are closed at ground level with a reinforced concrete slab with a hole for the hatch well construction. You can also use ready-made concrete circle for the well. The main thing is to protect the contents from precipitation and various debris.

- The design with water is equipped with a more graceful meter ledge and a canopy over it, to ensure convenient water intake both manually and with the help of an automated pump.

Conclusion

Wells serve both for the extraction of clean water and for the filtration of wastewater. Their construction on their own site significantly improves and facilitates life. The best building material for them is concrete due to the combination of their positive qualities.

The main stage of the installation works - the filling of the walls of all types of wells goes the same way, overcoming the stages of installation of formwork and reinforcement. In deep constructions, you can build walls outside, and then lower them to the desired depth by undermining the ground.

The video in this article will introduce you to additional information that relates to the material parsed.

Monolithic concreting is the most reliable way to build a well.