Connecting the pumping station to the well: tips on the

In arranging the well water supply system, the master has to solve a number of rather complex tasks. And one of them is to connect the pumping station to the well with our own hands - after all, only with the proper installation and setup of this unit we will receive water without interruption and in the required volume.

Below we will talk about what these systems are, and also describe in detail the process of their installation.

Device layout

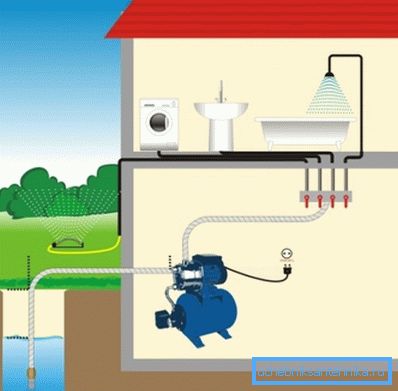

For lifting water from wells and shallow wells up to 20 meters located in private households, most often either submersible pumps or automatic pumping stations are used. And it is precisely the second option that has recently become more popular, since the structure of such a station includes a whole complex of equipment that ensures the smooth operation of the entire system.

As a rule, the pump unit is completed with such details:

- The pump itself, often centrifugal type. The device is responsible for lifting water and transporting it through pipelines.

Note! Sometimes such a pump is installed in addition to a submersible pump, especially if there is a need to raise water from a deep well to the upper floors.

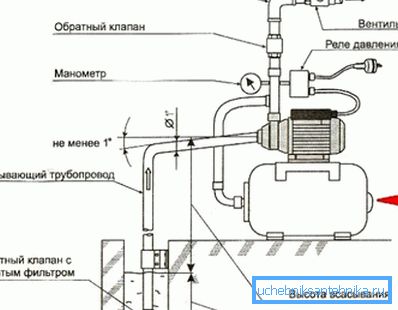

- Hydroaccumulative capacity, which is a tank, divided by a membrane into several sections. Thanks to this design, the pressure in the system changes more smoothly, and the automation, which is responsible for starting the pumping part, turns on less frequently. Also, the use of the battery softens hydraulic shocks, which has a positive effect on the state of all connections.

- Pressure switch reacting to a change in the system. As soon as the pressure level in the pipelines and / or accumulator falls, the relay starts the pump electric motor and water begins to flow into the pipes from the source.

- Manometer for recording changes.

A water intake system is used to deliver water from a well or a well, which is a suction hose equipped with a check valve. At the outlet is mounted the central pipeline, which connects the automatic station with the house and all points of consumption.

Assembly technology

Choosing a place

Before you begin work on the installation of the pump unit, you must select a suitable place.

The requirements for it are as follows:

- First of all, The system should be located in close proximity to the water source. This will allow us to ensure the most efficient water intake without loss of power.

- Secondly, The device must be protected from the effects of precipitation. Of course, the majority of pumping stations are produced in sealed enclosures, but they are clearly not designed for permanent work in the rain and snow.

- Thirdly, the installation site must provide access to the system for commissioning and preventive maintenance.

- Also you should not forget that the pump electric motor makes quite a lot of noise, therefore you shouldn’t mount them in living rooms.

From this point of view, the basement of the house (if the well is located in the immediate vicinity of the foundation), pit or caisson will be an ideal place for installation. You can also place the control station in the well itself, securing it on a special shelf under the neck.

We lay pipes

After the installation site is chosen, we need to lay a pipe from the house to the water source.

Instructions for performing work in this case is quite simple:

- We dig a trench with a slope towards the well. The depth of the trench should be somewhat greater than the depth of soil freezing - so we protect the pipe from the formation of ice jams.

- At the bottom of the trench we fall asleep a sand pillow up to 20 cm thick.

- We put the pipe, pre-wrapping it with insulating materials.

Note! As an alternative to insulation, a self-regulating heating cable can be used.

- In the foundation we make a hole through which we start the pipe to the basement or the underground.

- We attach the pipeline to the internal wiring, carefully insulating all areas in unheated rooms.

- We connect the other end of the pipe to the pumping station through a special fitting with a non-return valve and a mesh for cleaning suspended particles. The price of such a part is small, but its use significantly improves the stability of the system.

We connect the unit

Next we need to connect and run the unit itself.

The connection scheme of the pumping station for the well is quite simple, and it can be realized with even minimal skills:

- To begin with, we are preparing a base on which the station itself will be mounted. Best of all, a small podium made of brick or cast from reinforced concrete is suitable for this. The minimum height of such a podium is about 20 cm.

- Directly under the legs of the unit is to put a rubber mat with a thickness of about 10 mm. Elastic material will effectively compensate for vibrations, reducing equipment wear and reducing noise.

- The legs of the pump are mounted on a rubber gasket and fixed with anchor bolts with wide washers.

Next you need to attach a water intake hose.

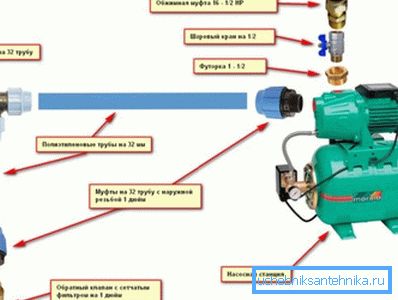

To connect use:

- Inch coupling with male thread.

- Steel or bronze corner with external thread.

- A suitable non-return valve that ensures uniform water flow into the system.

- Connection- "American."

We connect all the parts in a single system, connecting the water intake pipe to the pumping part. At the same time it is necessary to monitor the tightness of all joints.

By the same method, connect the output pipe. As noted earlier, here you can install a coarse metal mesh filter.

You can optimize our system by installing a pre-filter in front of the pump part. Using this low-cost device allows you to extend the life of the pump, because the clay and sand particles entering the flow section are a major factor in the wear of parts.

Note! Centrifugal models suffer from poor-quality water somewhat less than vibratory ones, however, for them, installing a filter can be considered highly desirable.

Pre-launch configuration

After completion of work with the hydraulic part, it is necessary to perform the initial adjustment of the entire system:

- To adjust the pressure in the pump through a special technological hole fill in about two liters of water.

- Perform a test start-up of the unit, fixing the moment of starting and stopping the system. The optimal shutdown rate is from 2.5 to 3 bar, the pump part should be switched on by 1.8 - 1.5 bar.

- If deviations from these figures are noted, then it is necessary to open the cover on the pressure switch and calibrate it by rotating the adjusting screws. As a rule, they are marked with a marking fixing the direction of increase and decrease in the indicator.

After adjustment is completed, the pump can be connected to work in normal mode.

Conclusion

The scheme of connecting a pumping station to a well or a well given here is optimal from the point of view of reliability and minimization of labor costs. Of course, it can be improved, but for the beginner it will be quite enough and this information. Following the recommendations, as well as having studied the video in this article, you can easily complete the installation and basic setup of the water supply system.