Core, sludge and casing for wells

Given the very large loads that are possible during the extraction and supply of artesian water, as well as the drilling technology itself, as a rule, steel casing for wells is used as a barrel for a column of water. In addition to these, more column and slurry sections are used, but all this material still serves one purpose. Below we will talk about this in more detail, and also, as a supplement, see the thematic video in this article.

Pipes

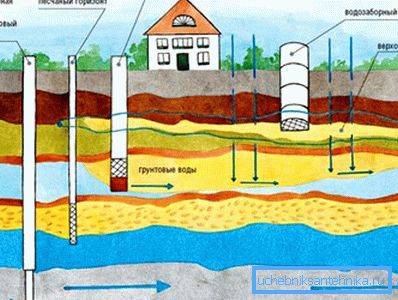

Note. It should be borne in mind that not any penetration is artesian, but only that which reaches the aquifer on limestone, and all the rest, less deep, are made on the sand. In connection with this, the length and diameter of casing for wells changes, because at different depths and loads are different.

Classification

- First of all, let's understand what a casing is for a well in order to get a clearer idea of the purpose of other types used in drilling. So, the casing serves to fix the crumbling walls of the penetration itself and to isolate the water shaft that is formed during drilling. For fixing with each other, three types of docking are used - nipple, non-stick and coupling connection (when the components are screwed into each other).

- The core and casing for the well in appearance and technical parameters are practically the same, but they have different purposes when arranging the source. The column is used for the selection and transportation of the core core receiver, and the drilling itself in such cases is called core. The advantage in this case is that the penetration is carried out with minimal destruction of the rock on the walls, which facilitates its further arrangement and operation.

Note. Based on the foregoing, the definition of a columnar during the passage of the layers is a core lifter. But the definition of casing refers to the same element, but in the process of its operation.

- Such arrangement, as in the photo above, is a pipe that is plugged from above, but has side holes. It is designed to protect the pump from slime ingress into it (large and small solid particles from the ground).

Technical specifications

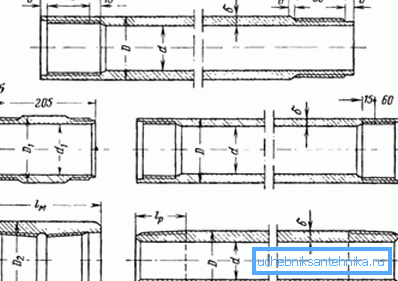

According to GOST 6238-77 (UDC 622.245.1: 006.354), a metal casing for a well can be used mainly for core drilling and an internal trapezoidal thread is cut at its ends with a standard pitch of 4 mm. As we already mentioned, their length is very different and can be from 1.5 to 6m, but it also depends on its cross section. Docking takes place with the help of a nipple, which is a pipe with identical external thread on both sides (see also the article Business Plan: drilling of wells on a commercial basis).

In those situations when a small section casing is required, non-stick metal pipes are used, at one end of which internal threads are cut and at the other end external threads are still with the same standard pitch of 4 mm.

Given the small strength of the walls of the material, they are mainly used for casing wells on the sand, that is, where it is possible to penetrate to the minimum depth. Such a device is somewhat cheaper due to the saving of component parts, because here the assembly does without a nipple.

Note. Core casing elements with a nipple and a non-stick threaded connection are made of steel, where the strength group is marked M, K and D, as required by instructions from GOST 6238-77.

For the production of gas and drilling for water during rotational and shock-mechanical drilling, another, third type is used, this is a steel casing pipe for a well with a coupling connection. According to GOST 632-80 (OKP 13-2100), steel with strength groups C, D, K, E, L, M and R is used for production. There is an external right tapered thread at the ends, only here the pitch is already 3.175 mm.

The taper of the thread, where the diameter of the casing for the well is from 114 to 168 mm, that is, a small section, is 1/32, and where the diameter is greater than that specified earlier, the taper is 1/16 - two times smaller.

Couplings have an identical thread, but already internal, with a zinc coating to protect against corrosion. The length of the constituent elements with such a connection varies from 9.5 to 13m, where the external thread is covered with paint for safety.

For casing passages with a large diameter in accordance with GOST 10706-76 (ST SEV 489-27) steel is used with a section from 426 to 1420 mm. Assembly (connection) of the column is carried out by welding.

In addition, plastic (polyethylene, polyvinyl chloride, polypropylene), as well as fiberglass is used for fixing walls when penetrating. Such materials are especially popular on moisture-saturated soils, that is, in an aggressive environment for steel. In the past, (and some are doing it now), asbestos cement was used, but such a composition is harmful to health, and it is better not to use it.

In special cases, double casing is used - on top - metal, and in the middle - plastic, but the price of such a project is quite high and due to the high cost it is used extremely rarely.

Conclusion

Casing pipes of different geometrical parameters (length and width) you can easily purchase in hardware stores, as well as from drillers. But do not forget that without a license, you can pass to a depth not exceeding 80m (see also the article “Well in the country house”).