Cork cock: device, application, problems

How does a cone (cork) crane? Where are these products used? For what, for example, cork crane 11B6BK DU50 is used? How good are these elements of valves in heating and water supply systems against the background of alternatives? Let's try to answer these questions.

What it is

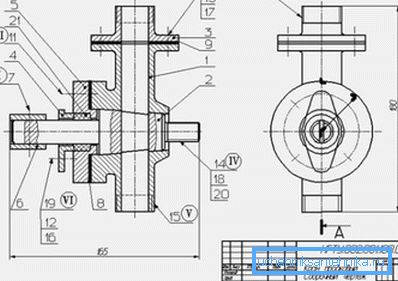

Schematic diagram and materials used

This is the name of a locking or regulating device, the main element of which is a cork - has the shape of a full or truncated cone with a through channel and comes in contact with the body with all lateral surfaces. Impermeability to water, air, gas or other medium conveyed by the pipeline is ensured by the absence of a gap between the plug and the walls of the housing.

The device of the cork crane implies a considerable area of friction and, as a result, a considerable force required for turning. Obviously, with a large pipe diameter, it will become unacceptably large; Not only that: sticking surfaces will further increase resistance.

That is why corrosion resistant materials with a low friction coefficient - cast iron and brass - are traditionally used to manufacture cork cranes.

Please note: due to the design features and the low mechanical strength of the metals used, the diameter of cork cranes rarely exceeds 100 mm, and the working pressure is 16 atmospheres.

There are no rules without exceptions: if desired, a cork-through valve with a diameter of up to 200 millimeters can be found on sale in a steel case.

However, those valves that can be found in the basement, he has little to do:

- To facilitate the rotation of the tube is used gearbox with a steering wheel.

- The cork is still made of cast iron: if two steel elements are attached to each other, even the gearbox will not help to break them.

Case sealing

As the valve blocks the movement of water or gas in the pipeline - it is easy to understand. And how is the absence of leaks in the external environment ensured?

Tension

The stopper passes through the valve body through. Its threaded shank when tightening the nut screwed on it presses the cap to the body with considerable force. The absence of a gap guarantees the absence of leakage both through the valve through the pipeline and into the external environment.

Curiously: when the valve is working, the quality of grinding surfaces improves over time.

Spring

The gas cork cone valve, which can be seen on the gas stove in most of the Russian apartments, is arranged somewhat differently: the cork is pressed against the body with a spring, not a nut. A small clamping force, coupled with lubrication, provides a moderate effort to turn the stopper; however, the maximum working pressure of the structure is more than small.

Stuffing box

Finally, a cork-and-gland valve was used on a large scale for heating and water supply: the gland packing around the stem ensured that there were no leaks. As a rule, braided graphite gland was used.

The way the packing was clamped usually depended on the valve material:

- Brass products used crimp nut.

- A cork cast-iron crane often used a pair of bolts to press the gland to the casing lugs to crimp the gland.

Ways to connect the body with the pipeline

There are actually only two of them:

- Flange. Adjacent flanges are attracted to each other by four to eight bolts; tightness is ensured by a paronit or rubber gasket.

- Threaded, or coupling. Sanitary flax and artificial sealing materials are used for sealing.

Depending on the nominal diameter of the connecting pipeline, the remote control (conditional passage) of the valve is indicated. Domestic documentation uses the metric system; The remote control roughly corresponds to the internal diameter of the pipeline in millimeters. Imported goods are more often marked in inches:

| Do | Size in inches |

| 15 | 1/2 |

| 20 | 3/4 |

| 25 | one |

| 32 | 1 1/4 |

| 40 | 1 1/2 |

| 50 | 2 |

Application

Let's give some examples of use of cork cranes in their various executions.

- The most obvious example is the samovar tap. Cork in it is held in the body of the crane only by its own weight.

- Soviet-style mixers with a lever switch were not very comfortable to use and often flowed; but they were practically unkillable. Breaking a lever or a cork was not a trivial task.

- Three-way plug valves were used to adjust the temperature in the apartments: depending on the position, they allowed the flow of coolant through the battery, through a jumper or completely blocked it.

By the way: the last function of the crane was the cause of the fierce hatred of the mechanics serving the housing estates built up by Khrushchev. It was not immediately possible to figure out which of the tenants on the riser blocked the tap.

- We have already mentioned gas cranes of the Soviet type. The cork valve against the background of the screw then widespread really looked much more reliable and guaranteed no leaks.

- Finally, along with the screw valve, the cork stuffing box was the most common element of the valves of heating and water supply systems in the 60s and 80s of the last century. It was there, in particular, that the 11B6BK DU50 valve mentioned at the beginning of our material was massively used: it was mounted on the insetting of hot water supply and heating in the elevator nodes.

Advantages and disadvantages

What do cork taps look like when compared to plumbing alternatives?

Let's start with praise in their address.

pros

- Unlike screw valves, they do not need to be oriented in a certain way in the direction of water flow. The gap valve does not threaten simply due to the lack thereof.

- A straight and wide through channel in a traffic jam creates a fairly moderate hydraulic resistance - again, unlike the winding passages in a screw valve.

- For the same reason, cork valves are never clogged with scale, sand and rust. Garbage simply has nowhere to stay in them.

- From modern ball valves cork favorably differ more resistance to high temperatures.

By the way: 150 C, maximum values for a ball valve, are the temperature limit on the supply line of the heating main at the peak of the winter cold. Higher values are achievable only in steam heating systems, which are currently used only in a few industrial enterprises.

Minuses

The author’s experience with cork valves in heating and water supply systems makes it possible to formulate the following main complaints about them:

- And cast iron and brass valves with a long idle boil. To turn them after five years of inactivity requires an effort that is quite capable of tearing the thread on the sgon.

- After the notorious period of inactivity, the slightest turn of the valve leads to water leakage through the gland. Yes, this is a problem - common to all products with stuffing box; however, in the case of a screw valve, it is solved by its full opening. Here you have to fill the gland again.

- By the way, about the gland: you can fill it only by first blocking and dropping water. What is the reason for the instruction? If you open the valve under pressure, the altered plug is likely to fly into your face at the front of the water flow. At best, cold; at worst, scorching hot.

For comparison: the valve with ground cheeks for packing stuffing with your own hands just enough to block.

- Unseal (tension) valve must be loosened before opening or closing, which is accompanied by water leakage. Especially touching when you are under the valve. If you do not loosen the tensioning nut, there is a real chance of tearing the thread from the cork.

- The rod for turning has to be taken with an adjustable, horn, or (most often) gas key. As a result, often used cranes are easily recognizable by the rounded, if not practically absent, above the rod stock.

- For all that, the price of the cork valve is not lower, and often higher than the ball counterpart of the same size.

Conclusion

The findings are rather disappointing. The obsolete design has already lost the battle for the plumbing communications market and can be used only in highly specialized industrial pipelines.

In homes where there is a three-way cork valve under the radiator, we can only recommend replacing the supply lines as soon as possible.

As always, in the video in this article the reader will be able to find additional thematic information. Successes!