Coupling ball valve 11b27p1: device, characteristics,

What is a brass ball coupling 11b27p1? How does it work? What do modern ball valves look like against competing solutions? Where can they be applied? Let's figure it out.

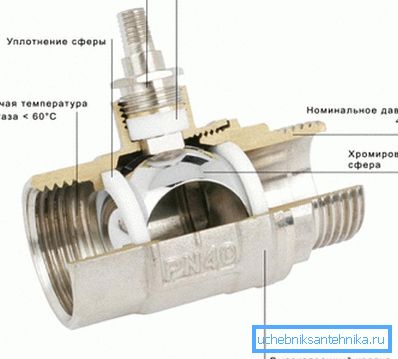

How it works

Brass ball-type coupling taps brand 11b27p arranged quite traditionally for this type of valves.

- The main element of the valve is a brass ball with a through hole. Depending on its position, the flow rate of the working medium through the housing is opened or closed.

Useful: like all other types of valves, ball valves are not intended for throttling (cross-country adjustment). They have only two working positions - open and closed. When the valve is operating in a half-open position, the body between the sealing rings is gradually filled with slag.

- The notorious low friction material sealing rings enclose the ball on both sides, ensuring tightness in the closed position.

- The stem passes through the hole in the housing and is sealed with a gland-like seal — a polymer ring, which is pressed from the top by a washer.

- The washer is fixed on the rod with a handle (lever or butterfly) and a nut.

Specifications

The technical characteristics of the 11b27p1 ball coupling valve are also fairly standard.

| Parameter | Value |

| Body and stem material | Lead brass LS59-1 |

| Ball material | Lead brass LS59-1 with chrome-copper-nickel plated |

| Handle material | Aluminum AK-7 coated with epoxy polyester powder paint |

| Material of ball and stem o-rings | PTFE |

| Through hole | Full bore (corresponds to the control of the attached pipe) |

| Working temperature | -30 - +150 С |

| Operating pressure | 16 kgf / cm2 |

| Life time | At least 10 years |

| Wholesale price | 96 - 105 rubles |

It’s probably worth adding a few comments to the dry numbers:

- The material of the body and the ball is exclusively resistant to electrochemical processes.. Brass does not form a galvanic couple with any of the metals used.

- The thermal stability of the fluoroplastic allows it to work not only in the internal engineering systems of buildings, where the maximum temperature of buildings is limited to 95 - 105 C, but also in heating mains and elevator nodes with a flow temperature of up to +150 C. Actually, the ball coupling valve 11b27p DN15 RU16 is often used as a control valve in the elevator.

The actual service life of the valve in normal operating conditions is a couple of times higher than the calculated one. Simply put - by installing it, you will hardly be forced to buy a replacement in the foreseeable future.

Regulations

Which GOST on the ball coupling 11b27p1 currently in effect?

- The material of the housing, the rod and the ball complies with GOST 15527-2004 pressure-treated copper-zinc alloys.

- Handle material must comply with GOST 1583-93 Aluminum casting alloys.

- The climatic version of the valve is evaluated according to GOST 15150-69 UHL 4, and tightness - according to GOST R 54808.

- Finally, the product as a whole must comply with the requirements of the interstate standard GOST 21345-2005 Cylindrical, cone and ball valves adopted by 12 states of the former USSR.

Nuance: the last standard regulates the production of valves for operating pressures no higher than 250 atmospheres. For ultrahigh pressures - your requirements.

We mention a couple of key requirements of GOST 21345-2005.

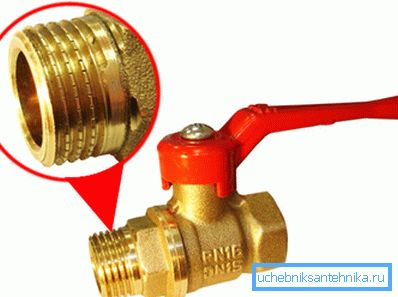

- The effective diameter (the size of the through groove in the ball) of the valve with the size up to DN 350 inclusive must be at least 95% of the diameter of the inlet of the housing.

- Defects in the thread, bringing it beyond the average diameter, should not have a total length of more than half a turn. In this case, defects should not interfere with the execution of the threaded connection of pipes.

Classmates

Along with the ball, in the plumbing stores can be found cork and screw valve. Let's compare the product we are studying with them.

Cork

The cork valve requires considerable effort to reposition the cork: the brass or cast iron surfaces of the contacting parts have a fairly large area. In the case of a ball valve, sliding a nickel-plated ball with an ideal surface over the seat of a polymer with an extremely low coefficient of friction does not have any noticeable resistance to pressing the lever.

The gland packing of the cork valve begins to flow at the first turn of the cork. The gland is inevitably produced even when idle: any mechanic will confirm that in order to have no leaks it has to be packed once every couple years. Polymer ball valve seals does not require maintenance in principle.

Screw

Compaction issues are relevant here. The use of rubber sealing rings does not completely solve them: rubber eventually loses its elasticity and leaks.

In addition, the device screw valve provides the owner with a number of exclusive problems.

- The complex shape of the circuit increases the hydraulic resistance and contributes to the accumulation of slag under the valve.

- The valve should be set with an arrow in the direction of the flow of water. Reverse current can tear the valve.

- The rubber gasket on the valve has a limited service life (rarely more than 3 to 5 years). All-metal valve will not block the water if there is at least one grain of sand between it and the saddle.

None of the problems listed for the ball design is relevant.

The conclusion is a bit predictable: competitors have no chance. If you are going to install plumbing or heating with your own hands, the obvious instruction is to opt for ball valves.

Application

What sizes of cranes are required when installing plumbing communications in a house or apartment? Where exactly should they be applied? Let's give some examples.

The spherical coupling 11b27p1 diameter of 15 mm is used:

- On the inputs of cold and hot water in the apartment.

- As a control valve for temperature and pressure measurements.

- On inserts in the plumbing of individual plumbing fixtures (toilet cistern, sink, sink, etc.).

A ball valve 11b27p1 with a diameter of 20 mm is used to cut off individual heating devices from the heating circuit. He can be put on the jumper in front of the radiator.

Captain Obvious reminds: if both the jumper and the battery connections are simultaneously closed, the circulation in the riser will completely stop. Soon the neighbors will come to you, headed by a mechanic, and will begin to utter evil, offensive words.

The spherical coupling valve 11b27p1 with a diameter of 25 mm is mounted on the risers of the water supply and heating, on the dumps of the elevator assembly and on the inlet pipes of the boiler.

Ball valve 11b27p1 diameter of 32 mm can be used on risers in high-rise buildings and on the pouring of the heating to cut off certain sections of the circuit.

Ball valve 11b27p1 diameter of 40 mm is used in the gravitational heating system (when inserting the pump, it breaks the bypass). It, along with larger diameter valves, can be placed in water meter units and in hot water tapping boxes in elevators.

Conclusion

We hope that our acquaintance with the representative of the domestic sanitary equipment was quite informative. The reader will be able to study additional subject materials by viewing the video in this article. Successes!