Coupling crane: manual for installation, operation and

The DN15 coupling valve designed for connection to a half-inch pipe is a fairly universal device. It provides sufficient tightness of the channel overlap, and if necessary, it opens easily and allows you to control the flow of liquid or gas in the pipeline.

However, the use of such cranes has a number of nuances, and therefore below we will provide some useful tips.

Product design

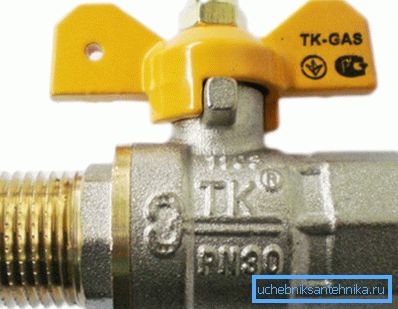

Coupling ball gas valve, as well as products intended for water pipes, fuel lines and other communications, has a fairly simple design. On the one hand, it simplifies the process of production of products (hence the quite affordable price), and on the other hand, it increases the reliability of operation of this unit.

The main elements of the system are:

- The body of the product is a fragment of a pipe of the corresponding diameter with expansion, inside which the locking mechanism itself is located. The cross section of the crane is usually fixed in the marking: for example, muff ball valve DN 65 suitable for installation on pipes with a diameter of 2? in.

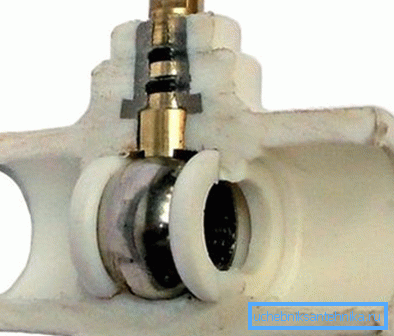

- Seals - special-shaped rings made of Teflon or other polymer, which provide sealing of the channel when the mechanism is in the closed state.

Note! The presence of appropriate seals is a decisive factor that ensures success during repairs. So, whenever possible, when buying a crane, it is worth buying a set of such parts, since they wear out the fastest.

- A bolt ball is a metal sphere with a through hole, which, in fact, passes through the contents of the pipe. It should be noted that the GOST on the ball valve provides for the presence of both a full passage (the diameter of the hole corresponds to the diameter of the pipe) and a tapering passage. When choosing a model for installation, it is worth further clarifying this feature.

- Rod, controlling the movement of the bolting sphere.

- Handle used to open and close the tap. Depending on the model, the device can be equipped with both a standard butterfly crane and a lever-type handle that allows you to control the structure with less effort.

This system works quite simply: when you turn the knob, the sphere rotates, and the lumen of the hole in the sphere is aligned with the lumen of the pipe. The greater the proportion of this combination, the higher the head content.

Crane operation

Methods of selection and installation

Before you purchase and install such a product, you must understand the whole list of parameters.

Below we give recommendations that will allow you to avoid problems associated with the exit of the crane during operation.

- The first thing you need to pay attention to is the design of the connection. According to experts, the tension type provides greater tightness than the stuffing box, because it is to give preference to such products.

- Next, look at the diameter. It is important that the sections of the valve itself and the pipe coincide perfectly, so that we carefully study the marking. So, for the three-inch pipeline we select the coupling ball joint DN80.

- The following is the type of thread. On sale you can find models with any combinations of external and internal cutting (coupling-coupling, coupling-union, union-union), so it is very important to think in advance about which model we need.

- Finally, on some products the preferred direction of the water flow is indicated. If you chose such a crane, then it should be installed in accordance with the marking: this way the work of the locking part will be more reliable.

- Finally, it is worth looking at the pen. Its size should allow without obstruction to fully open and close the faucet, so that in tight spaces (for example, in a sanitary box) it is better to use butterfly handles.

Products for pipes of coupling type are assembled with their own hands no more difficult than any other:

- On the thread winding plumbing winding, providing a sealing connection.

- We install the crane, screwing in fastenings manually.

- Then finally tighten the connection using an adjustable wrench, after which we check the tightness.

Note! It is not necessary to tighten the entire length of the pipe thread, as in some cases this may lead to the destruction of the joint under excessive load.

Self repair

One of the unpleasant features of coupling design is the complexity of their repair. However, if you know how (and have a spare set of sealing rings on hand), then you can even repair a three-way valve with a rather whimsical mechanism.

The instruction is:

- We dismantle the product, since the repair will require quite complicated manipulations. If we have a properly installed ball valve, the clutch should loosen without super efforts and damage.

- Turn off the handle lock, then remove it from the rails.

- Using the adjustable wrench, unwind the valve body itself. Here you need to be careful, because the effort will need a lot, but it should not damage the thread.

- We take out the sphere and sealing rings, after which we carefully examine all the details.

- If the ball has no damage, then the product can be repaired. To do this, we replace the rings, installing new Teflon gaskets of the appropriate diameter.

Note! In some cases, the replacement itself requires the ball itself, but usually the condition of the body also leaves much to be desired. So it is necessary to install a new product with an adequate margin of safety.

- Performing operations in the reverse order, we assemble the crane and install it in its place. We control the quality of performance of work by carrying out a test supply of water.

Conclusion

Not only a professional plumber can choose, install and even repair a continuous ball-valve with a ball valve. If you study the above recommendations, as well as view the video in this article, then any master who has the skill and patience will cope with this task.