Crane 11b18bk: device, application, problems

In this material we have to study the three-way clutch valve for the pressure gauge 11Б18БК. We will find out how this element of the stop valve is arranged, what it is made of and for what purpose it is used. In addition, we will examine the typical problems of the valve.

Device

Our hero is a cork tension valve. Switching of modes is carried out by a rotary conical stopper with a through stroke in it. Gland or seal completely absent; sealing provides only grinding in the working surfaces of the cork and the valve body.

Please note: the end of the plug passes the case through and is threaded. The nut with a washer screwed on it allows you to adjust the degree of clamping the plug to the body; increase clamping is used to eliminate leaks.

The gate 11B18BK is issued in several options of execution.

Two threads

In the simplest version, it is an ordinary straight through coupling valve with two internal threads.

There are only three options for the size of pipe threads:

- 1/2 inch (DU15) pipe threads on both sides.

- Metric thread M20x1.5 on both sides.

- The combination of pipe and metric threads.

Two threads, handle

The difference of this performance from the previous one is only in the fact that the cork is supplied with a convenient handle. Without it, the valve has to be opened with a horn or (more often) with a gas key, which often leads to a breakdown of the faces on the rod.

Two threads, flange

In the version with a pipe flange, a full-fledged 3-way crane appears in front of us, allowing to realize the following configurations:

- The threaded inlet is closed.

- The inlet is connected to the second thread.

- The inlet is connected to the flange.

- The inlet is connected to the thread and the flange.

Curiously: this performance can be found under its own name - 11B38BK.

Two threads, flange, knob

The configuration speaks for itself: the product with a pair of threads and a flange is equipped with a handle.

Specifications

Here are the main characteristics of the valve:

| Parameter | Value |

| Body and Cork Material | Stainless steel, brass |

| Working environments | Water, steam, oil, oil products, air |

| Maximum working pressure | 16 atmospheres (kgf / cm2) |

| Maximum working temperature | For water, air, oil and oil products - 150С, for steam - 225С |

| Price | 125 - 190 rubles depending on the manufacturer and execution |

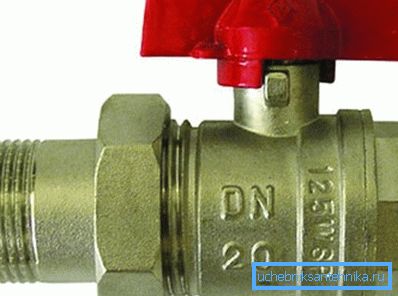

Useful: size and working pressure are usually present in the labeling of valves. For example, the inscription DU15 RU16 means that we have a product with a conditional passage (approximately corresponding to the inner diameter of the pipe to be attached) 15 mm and a working pressure of 16 atmospheres.

Application

The most reasonable use of a coupling plug valve without a flange is as a fitter on a heating riser or a control valve in a route, water meter or elevator assembly. Installation as a shut-off valve that overlaps risers or liners is also practiced; however, this practice is flawed. The reasons we will explain later.

The three-pass version of the valve with flange is used for the sole purpose - under the pressure gauge DU15 or M20. The flange is used to connect a reference pressure gauge: any device requires periodic calibration.

Problems

They flow directly from the valve device.

- To change the position of the cork it requires quite a lot of effort. Yes, brass is a metal with a relatively low friction coefficient, not prone to sticking or oxidation; besides valves are supplied by manufacturers with lubrication applied. However, believe the author’s experience, an attempt to close or open a valve that has not been used for a long time often ends in a broken stem. Tension valves against the stuffing box are distinguished by the maximum effort of clamping the plug to the body and, accordingly, the maximum resistance to its rotation. A strong loosening of the clamping nut leads to leaks, and often boiling water flows from under the cork.

- A scratch on the body or the cork, a piece of slag between them or a grain of sand causes the valve to start to poison. He either passes the working medium through himself into the pipeline in the closed state, or, which happens much more often, gives a flow between the plug and the casing. When you try to tighten the nut on the tail of the cork, solid enough garbage is pressed into relatively soft brass, leaving ground surfaces defective and increasing resistance to opening. Often, an attempt to tighten the nut ends completely with a completely torn off shank.

It is precisely the latter problem that is why the author strongly recommends the use of a tension cork valve only as a relief valve.

Instructions for cleaning the valve from slag or sand is simple and obvious: just unscrew the nut on the shank and remove the plug. One problem: for this, you first need to completely reset the pipeline on both sides of the crane. In the event that it turns off the heating riser, you will have to reset both the riser and the filling (that is, in fact, the whole circuit).

Findings:

- Valve 11B18BK perfectly performs its functions as a control. Its version without flange can be used as a waste tap.

- When you install the valves through the valves yourself, it is better not to look for any extra adventures and use well-proven ball valves.

Conclusion

We hope that our recommendations will help the reader to avoid mistakes in the process of selecting equipment for their own projects. The video in this article, as usual, will offer additional thematic information. Successes!