Crane 11s41p: device, characteristics, advantages

What is a ball valve 11s41p? How does it work? What are its main specifications? How good is this valve against the background of alternative solutions? Let's try to find the answers.

Two in one

It is worth starting with the fact that, under practically identical names, two products that differ significantly from each other are made.

- Giving the name of this article 11s41p - steel flanged valve.

- Ball valve 11b41p - brass valve with installation on pipe threads.

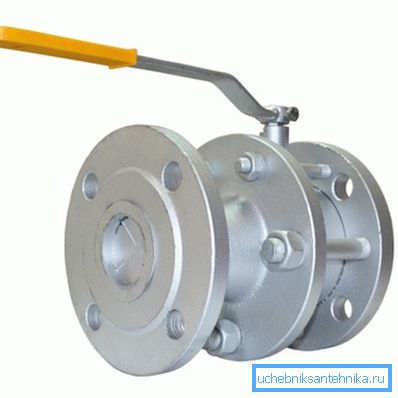

Flanged steel

The product with flanges and steel casing is made for pipelines of large diameters (DN 50 and above). The flange connection allows the installation and disassembly of the product in the shortest possible time.

In addition: installation on the flanges is possible on a straight section of the pipeline, the length of which is only slightly longer than the valve element. For comparison, a pipe coupling with the possibility of dismantling requires the installation of a booster, which increases the minimum installation size more than twice.

We give the technical characteristics of the ball valve 11s41p in steel housing with flanges, taken from the site of one of the manufacturers.

| Parameter | Value |

| The size of the pipeline to be connected | DU50 - DU300 |

| Working environments | Technical and drinking water, steam, chemically non-aggressive coolants, natural gas, oil and its products |

| Working temperature | -30 - +200 degrees Celsius |

| Operating pressure | 16 atmospheres |

| Body material | Steel 20 |

| Shutter Ball Material | Stainless steel 20x13 |

| The material of the sealing saddles ball | Fluoroplastic F4K20 |

| Rod O-Ring Material | Rubber IRP-1287 |

| Handle cover | Polyvinyl chloride |

On the flanged steel 11s41p useful to know a few things.

- Products of large sizes (as a rule, DN150 and above) are completed with a gearbox, reducing the closing and opening effort.

- The installation length of the product is equal to the installation length of the steel valve 30s41nzh, which allows replacement without adaptation of the pipeline.

- The manufacturer estimates the service life of the valve at 10 years or 2500 closing cycles - opening.

- The wholesale price of a product with a reducer with a size of 300 mm reaches nearly 100,000 rubles, weight - 288 kilograms.

- Valve body - collapsible. Its halves are pinched with nuts and growers.

Brass Coupling

Ball valve 11b41p seem to us much more familiar: it is a typical representative of the family of modern ball brass valves, which are massively used in the repair and installation of utilities.

| Parameter | Value |

| The size of the pipeline to be connected | DU15 - DU100 |

| Workspace | Water, water vapor, gas |

| Valve mass | 0.14 - 6.5 kg depending on size |

| Housing variants | Coupling coupling coupling coupling |

| Handle options | Lever, butterfly |

| Body material | Hot-pressed brass Lts400Sd |

| Shutter Ball Material | Chrome Plated Brass |

| Material saddles locking ball | Fluoroplastic F4 |

| Maximum working pressure | 16 atmospheres |

| Maximum working temperature | +150С |

As in the case of the previous description, it is worth making a few notes.

- In stores you can meet in large quantities coupling 11b41p in size up to DN50 inclusive. Large sizes are used extremely rarely because of the difficulty of installing hermetic threaded connections of considerable diameters.

- Yellow handle marking indicates that the valve is for gas. Red - for heating, hot and cold water.

- For gas, the working temperature is limited to a value of +50 C. The manufacturer’s instructions are not so much connected with the real danger of gas leakage at higher temperatures, as with the probability of an explosion of the gas-air mixture when it is heated.

Device

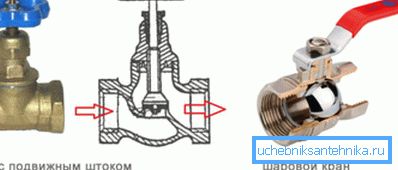

Despite the difference in appearance and materials used in the production, inside both versions of the valve are made according to the same scheme. The shutter is carried out by turning the handle, the transmitted rod on the ball with a through hole in it. Tightness is ensured by fluoroplastic ring seats - a polymer with a low friction coefficient.

Benefits

How do ball valves compare favorably with their main competitors - screw and plug valves?

- Unlike screw valves, the ball has a much lower hydraulic resistance.

Useful: the word full bore in the description of the valve means that its smallest internal diameter is equal to the internal diameter of the pipeline being connected.

- Ball valves require little maintenance. For comparison: both screw and cork gland cranes require periodic packing of the gland; screw additionally requires replacement of worn gaskets.

- The cork valve requires considerable effort to reposition the cork: when turning, the metal cork rubs against the metal of the casing. In the case of a ball valve in the role of a saddle, as already mentioned, plastic with a low coefficient of friction acts.

- The screw valve must be installed strictly along the arrow on the body. Counterflow can completely tear off the valve. Not only that: the valve's separation will be accompanied by a hydraulic shock, which is quite capable of breaking the threaded and fitting pipe connections of the engineering system.

The ball valve (as well as the cork one) of the valve can be placed in any position with its own hands during mounting.

- Finally, the housing of the screw valve collects all the pollution that travels through the HVS, HWS and heating systems. Under the valve seat valve, operated for at least a decade, you can always find deposits of silt, sand and scale. Gradually, they reduce the permeability of the pipeline to zero.

The ball valve simply does not have pockets that could accumulate slag.

Conclusion

We hope that the reader will not find verbose praises to the solution we are discussing with advertising: the author only shared his experience of communicating with various types of valves. Additional information on how the 11s41p crane can be used will offer a video in this article. Successes!