Crane butterfly features of the device of this type of

The butterfly ball valve is quite common, and this is due to a number of advantages that we will consider in this article. We will also define the basic rules by which you should choose a specific modification of the product so that it serves as long as possible. Such attention is no coincidence, because this crane can be put in almost any system.

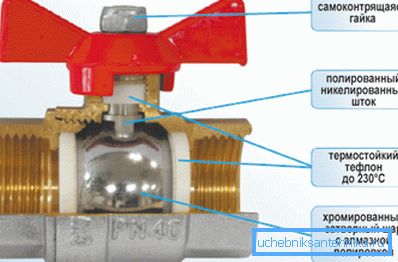

Basic construction elements

Regardless of the design features and the manufacturer, any node of this kind consists of several components:

| Housing | This element can be of two types, the first of them is a non-separable one, made in such a way that, in the event of faults, the node is replaced entirely, of course, the price of this option is small. The collapsible case has a more complex structure, it is heavier and heavier, but if problems arise, the product can be disassembled and replaced with individual consumables. |

| Locking knot | It is made in the shape of a ball and can be rigidly fixed or floating. In addition, the diameter of the inner hole may be equal to the nominal diameter of the crane, and may differ from it (usually in a smaller direction). The reliability of this element largely depends on the quality of its performance and the reliability of the material manufactured. |

| Swivel rod | It is also called a spindle, and it serves as an axis for turning the locking assembly. It should also be made of high-quality material and precisely fitted to the mounting holes in the housing; no, even minimal, play is allowed |

| Lever | It was the shape of the handle that gave the name to the cranes of this type. The double-sided handle resembles the profile of a butterfly's wings, this form is not accidental, this element is very convenient to use: opening and closing the valve is very easy |

| Sealing rings | In order for the ball to provide the necessary tightness, two fluoroplastic rings are placed between it and the body. This material is highly durable and wear resistant, it is much better against abrasion than traditional rubber. New word in seals - Teflon elements, their strength is so high that they can serve for decades. |

Note! It is best to purchase products of well-known manufacturers, it guarantees the quality and reliability of the nodes.

Types of products and their features

All cranes can be divided into specific groups depending on their design and other factors, consider the most significant of them.

Types of designs

Depending on the version and type of product, the following groups are distinguished:

- The direct-flow variant is used where overlapping of the flow of liquid or gas is required from time to time.. We can say that this is the easiest and most common option among all those considered. It is used in the case of repair of individual elements with their own hands: the system overlaps, and work can be carried out.

- Passing type is used where it is necessary to adjust the flow rate from time to time.. The design is designed in such a way that the adjustment is made as accurately as possible.

- The angular view is a node in which the direction of movement of the working medium changes in the desired direction.

- The mixing valve is designed to mix the two liquids in a certain proportion in order to achieve the optimum temperature or some other indicator.. Its design is different from the classical options, so you should choose such products especially carefully.

If we separate the constructions by throughput, we can distinguish three types:

- Non-full bore taps, in which the carrying capacity is about 40-50% of the diameter of the pipe on which the unit is installed. This option is not suitable for all systems, so it is used less often than others.

- Standard designs have a capacity of 70-80% of the diameter of the pipe on which they operate. As the name implies, this option is used most often and is the most common.

- Full bore nodes are able to pass from 90 to 100% of the diameter of the system. This is the most productive option, to which increased requirements of reliability and strength are imposed, since the wall thickness is less than that of other types.

Depending on the functional accessories, it is also possible to divide all taps into three groups:

- Locking devices are designed to completely block the flow. Moreover, the goal can be very different: from the on-off of water or gas, to an emergency shutdown of the system or floor for repair and maintenance of individual nodes and communications.

- Shut-off and control valves are used both to shut off the flow, and to adjust its intensity or change the ratio of the two flows. They are applied wherever any adjustments need to be made. (See also the article Connecting sinks: features.)

Note! If you get a tap for hot water, then you should choose an option with sufficient resistance to high temperatures.

- Special designs are designed to perform certain operations and functions.

Manufacturing material

The most commonly used options are:

- Cast iron products are used less and less, as the material is susceptible to corrosion and very fragile.

- Steel options are stronger, but also damaged by corrosion.

- Stainless steel is a very durable material, but its price is high.

- Brass and bronze are the most optimal variants combining quality and democratic cost.

- Polyethylene and polypropylene - new solutions that are of reasonable price and high durability. (See also the article How to choose a sink faucet: features.)

Conclusion

Butterfly cranes are the perfect solution for a wide range of designs. It is important to choose a quality option, and the video in this article will help with this; in it some important nuances are revealed in more detail.