Crane device: get acquainted with popular designs

The topic of this article is a crane device. We will get acquainted with the principle of operation and the device of several types of cranes and gates. In addition, we have to explore the typical problems of these products and how to solve them.

Mixers

In the most common modern faucets, valve and control devices of three types are used:

- Screw cranes.

- Ceramic Kranbuksy.

- Ceramic cartridges that allow you to adjust the temperature and water pressure with one lever.

To clarify: we deliberately do not affect the exotic kind of mixers with electronic thermostats. It is unlikely that a person who does not have professional skills will come up with the idea of repairing such a complicated technique.

Let us analyze the design and features of all three solutions.

Screw kranbuksa

The water is overlapped with a rubber-fitted valve that presses against the seat in the mixer body.

The valve can have two versions.

- The traditional solution is a movable valve inserted into the groove of a hollow threaded rod.. When the valve is seized in the stem, the gasket will rotate, clinging to the seat, which will lead to its rapid wear.

- Newer design - hex valve, which is squeezed by a rotating rod from the axle box body. The gasket along the entire stroke of the valve moves strictly progressively.

Obviously, in both cases, the stem must be sealed: when the valve is open, an overpressure is created in the body of the crankshaft.

The stem is sealed in one of two ways:

- Gland packing The epiploon is tightened by a washer from below and a nut-epalnitsa from above. This sealing scheme is used only in boxes with a valve that is inserted into the groove of the stem.

- Rubber sealing rings. Actually, most currently on sale Kranbuks refers to this type.

What problems are typical for screw boxes? Is it difficult to eliminate them with your own hands?

| Problem | Cause | Decision |

| When the tap is closed, water continues to drip or flow | Wear pads | Shut off the water; dismantle kranbuksu; replace gasket |

| The crane is cranked when closing | The thread on the rod or body is torn off. | Shut off the water, replace Kranbuksu |

| With the tap open, water flows through the stem. | Development of the gland or rubber seal | In the bush with the gland packing, several threads of a graphite gland are stacked around the stem with the valve and valve nut unscrewed, the socket is closed, and then pressed with this nut. Rubber seals change with dismantling and complete disassembly of axle box |

| Crane buzzes when opening | Valve beats in a turbulent flow of water | Peel off the edge of the strip with scissors or a sharp knife |

Nuance: the price of screw kranbuksy - from 35 to 45 rubles. If in the nearest plumbing shop there are no ring seals or a gland, instead of further searches, it is easier to change the axle box entirely.

Ceramic Cranbooks

The device of the ceramic crane is fundamentally different from the screw, despite their full compatibility.

- Water opens and closes with the mutual displacement of ground ceramic plates with cuts.

- The tightness between the seat of the mixer body and the plates is ensured by an annular rubber or silicone gasket.

Under normal operating conditions, ceramic boxes are much more durable than screw boxes and always hold water perfectly. Their malfunctions are associated only with the garbage that fell into the plate cuts: when they try to apply considerable force, either the edges of the notch or protrusions for which one of the plates is rotated when the lamb (crane handle) is rotated are cleaved.

Alas, the instruction for troubleshooting in this case comes down to replacing the entire axle box. Ceramic plates are not widely available.

Important: the problem of sand and scale in pipes is solved once and for all by installing coarse filters at the entrance to the apartment.

Cartridge

The scheme of his work differs from the principle of action of the ceramic box with two features:

- The movable plate does not rotate around its axis, but freely moves within the plane.

- The groove in it is not combined with one, but with two holes in the lower ceramic plate - for supplying cold and hot water, respectively.

For the displacement of the plate meets the movably mounted plastic lever. Problems with the operation of the cartridge in this case either arise because of debris in the pipes, or because of excessive force applied to the lever. It is better to forget the habit of blocking water with a sharp clap of hand on the handle.

What breaks in the cartridge:

- The plastic lever to which the screw fastens the handle.

- The plastic clamps holding the top ceramic plate.

- Finally, when you try to close a cartridge stuck with debris, you can chop the plate itself.

Like ceramic kranbuksa, the cartridge changes completely when it breaks.

How to do it?

- We take out the plastic stopper pressed into the handle.

- Unscrew the fastening screw hiding under it. It may have a flat head, a Phillips screwdriver or a hexagon head.

- Screw the decorative nut from the mixer body. Of course, without using a tool: chrome is easy to break.

- Already with the help of an adjustable or open-ended wrench, we unscrew the brass nut holding the cartridge, remove the cartridge itself and head to the store for a replacement.

Pay attention: cartridges are made with a size of 28, 35 and 46 millimeters. In order not to be mistaken when buying, take a sample with you.

Vent

Of the valves used in apartments and private houses, the most common are:

- Screw valve.

- Cork valve.

- Ball valves.

- Three-way valves (cork and ball).

Screw

And the description of the device, and the typical problems of screw Kranbuks fully apply to the screw valves.

Separately, it is worth mentioning only a few points:

- The space under the saddle usually becomes a pocket in which various debris accumulates. If the pressure in the faucets has fallen sharply - it is necessary to cut off the riser, unscrew the valve head and look into its body.

- In the 80s, an obscure domestic enterprise produced a large batch of valves with conical brass valves. When you try to close the water valve often tightly wedges; By twisting the stem, you are likely to vomit it out of the remaining valve seat. At the first opportunity, it is better to replace the valve of this design.

- If the valve drip seal, it is not always necessary to fill. It is often enough to unscrew the lamb until it stops: the thread on the rod will press the stuffing box through the washer located under it.

Cork

Water opens and closes by turning the cork with a slot in it. Water is held in the ground surfaces of the plug and housing.

The absence of leaks on the rod is provided in one of two ways:

- Clamping the cork to the body with a nut on the cork shank.

- Gland packing

The only problem of cork construction, which can be eliminated independently is the gland leak. For its packing, the water must be flushed on either side of the valve - otherwise there will always be the likelihood that the plug, not retained by the oil seal, will squeeze out at the slightest displacement.

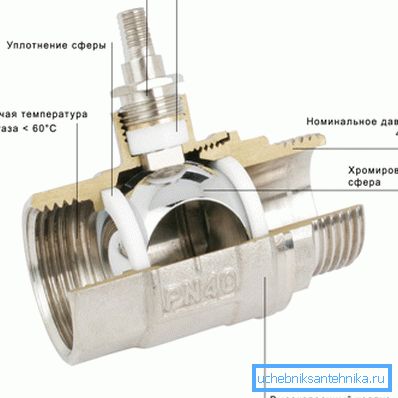

Ball

How does a ball valve - the most reliable and durable representative of valves?

Its device resembles a cork valve, but with several design changes.

- Cork is a ball with a perfectly treated surface.

- Tightness is provided not by lapping to the body, but by a pair of fluoroplastic or teflon ring saddles.

- The rod is sealed with a rubber or polymer ring.

Depending on the purpose, the ball valve device may vary considerably:

- The body can be collapsible (heels or threaded) and all-welded.

- Accession to the pipeline can be a thread (internal or external), flanges for pipes or pipes for welding.

- The saddles of the ball can be spring loaded to compensate for their wear.

Curiously: sometimes a small gap is intentionally left between the ball and the saddle. The ball is pressed against the seat by the pressure of the working medium.

The only typical problem of ball valves is the flow down the stem, which is eliminated by tightening the gland nut or winding the FUM tape under it.

Three way

What is the design and purpose of the three-way crane? The purpose is to redirect the flow of the working medium to one of the attached pipelines. For example, a three-way valve installed at the connection of the supply pipe to the radiator and jumpers is able to direct the heating system heat medium either through the jumper or through the battery, thereby adjusting the degree of heating of the room.

The device of a three-way valve and its typical faults completely duplicate the device and faults of the valves of the corresponding types. The difference between them is only in the number of taps and the shape of the cut in a traffic jam or ball.

Conclusion

We hope that our brief excursion into the valve device will help the reader to eliminate most of its faults. The video in this article, as always, will offer him additional thematic materials. Successes!