Crane du-80 on the 80-mm pipe: versions and their comparison

What stop valves can be used on an 80 mm pipeline? We will acquaint the reader with the designs of existing cranes and try to compare their functionality. We will immediately stipulate that the scope of our attention will be limited to plumbing: for example, a bitumen three-way valve with a heating control unit 80 will remain out of consideration.

Areas of use

To begin, let's find out exactly where in the communications of an apartment building pipes and shut-off valves DU80 can be used.

- Heating main input. Shut-off valves that cut off the outlet to the house from the highways can be located not only in the thermal well, but also in the basement - provided that the route passes directly through it.

Note: in this case, the taps remain in the area of responsibility of the heat transporting organization, despite their location within the perimeter of the house. The zone of responsibility passes through the first pipe flange of the inlet valves of the elevator assembly.

- Elevator hub. In it, the 80-millimeter fittings can be used at the inlet, between the elevator and the heating circuit, and in the hot-water connections.

- Water meter in the cold-water system.

- Finally, with the help of taps, certain sections of the water supply or heating circuits can be cut off.

Execution options

What kind of valves are used in engineering communications of the building?

Gate valves

The most common cast iron wedge gate is a retractable stem design, the expansion at the end of which holds a pair of cast iron cheeks with brass mirrors. A pair of response mirrors inserted into the grooves of the housing. The stem is supplied by rotating the handwheel with a threaded bushing.

The main advantage of the valve is a relatively low hydraulic resistance: the cheeks in the open position are completely removed outside the flow.

Disadvantages:

- The need for periodic packing the gland. It is produced even when idle.

- The formation of deposits on the mirrors and, as a consequence, the need for their periodic grinding.

- Quick wedge wear.

Screw valve

The handle or butterfly is attached directly to the movable rod, which is screwed into the thread in the valve body cover. A valve fitted with a gasket is movably attached to the inside of the stem, which closes the opening in the seat.

The only advantage of this design against the background of the previous one is that it is much easier to revise the screw valve DN80 with your own hands than the valves of the same size. Neither the welding of the wedge nor the laborious grinding of the cheeks are needed: it is enough just to stuff the gland and change the gasket.

All other design features look pretty dull.

- Hydraulic resistance is maximum among all types of stop valves due to the small size of the hole in the seat and the complex shape of the body.

- Installation is possible only in one position relative to the flow of water: it must press on the valve from the bottom. The counterflow guarantees the separation of the valve and the accompanying water hammer.

- Paronitic gasket with the inevitable erosion of the saddle requires great effort when closing, and the softer rubber is very short-lived.

Plug valve

Ground stopper with a through channel rotates in a brass or cast-iron housing. Tightness on the rod with a large crane is provided, as a rule, all the same stuffing stuffing.

Curiously, despite the simplicity of the design, the price of the cork valve is 1.5 - 2 times higher than that of the valve of the same standard size.

The advantage of the design is a fairly high resiliency and simple maintenance, which is reduced only to the periodic packing of the gland. The main drawback is a very significant effort required to turn the cork.

Ball valve

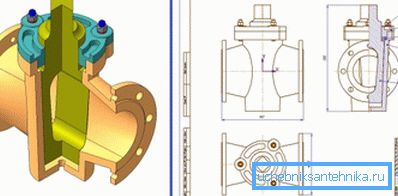

The ball valve of the DU80 device somewhat resembles a cork: in this case, the water is blocked by turning the shutter 90 degrees.

Differences, however, more than similarities:

- The cork has the shape of a ball with a through channel, with a diameter equal to the connected pipeline.

- Seal the ball with a pair of annular seats made of Teflon or Teflon, polymers with a low friction coefficient. Hence, a very moderate effort of turning the bolt.

- Instead of the gland, the 80 mm ball valve is equipped with a fluoroplastic or teflon sealing ring with an adjusting nut. She allows to press a sealant, compensating its wear.

By the way: it is necessary to tighten the stem seal, as a rule, after 1000 or more shutter cycles.

The valve body can be made of brass and steel, can be collapsible or all-welded, be supplied with flanges, pipes for welding or coupling pipe threads. The bolt is made of chrome-plated or nickel-plated brass, less often of stainless steel.

As an example, we present the main characteristics of one of the domestic products of this type. The model for us will be a ball valve KSHTF DU80 RU25.

| Parameter | Value |

| Body material | Carbon steel |

| Housing design | All-welded |

| Pipeline connection | Flanges |

| Shutter material | Stainless steel |

| Compaction | PTFE |

| Operating pressure | 25 kgf / cm2 |

| Working temperature | 150С |

| Retail value | 4129 rubles |

Evaluation

The author risks to appear biased, but still allows himself to give an extremely flattering characteristic of this type of valves. Judge for yourself:

- Hydraulic resistance, which creates a ball valve DN 80 - 80 mm steel pipe is superior. Precisely this: sediment and rust in the straight section of the pipe create greater resistance to the flow of water than a full bore hole in the stainless ball valve.

- Service crane is practically not required. About repairs and audits, you can forget.

- Installation - in any position and with any direction of water flow.

It seems that the instruction on the choice of elements of valves and fittings is quite obvious. All competing solutions on the background of a ball valve look like an outsider.

Conclusion

We hope that our recommendations will help the reader in choosing the optimal solution for their own purposes. As usual, additional materials can be studied by viewing the video in this article. Successes!