D20 ball valve - how not to make a mistake when choosing a

The number of key parameters that need to be taken into account when selecting valves, is the diameter, this size must exactly correspond to the dimensions of the pipe, otherwise you can forget about the tightness of the joint. For an unprepared person, some confusion may be caused by the use of such designations as "conditional diameter" or the size of the lumen, so it is necessary to clarify this question initially.

Small educational program

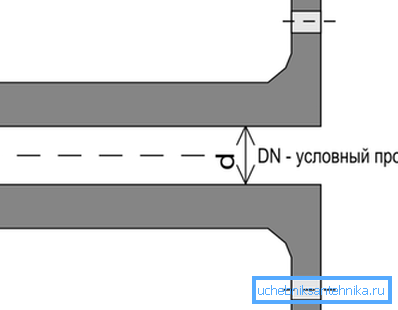

Each is familiar with the concept of diameter, but the concept of nominal diameter (D or DN) is used for pipes, as well as stop and control valves. For example, in plumbing stores the designation of a ball valve of 20 mm implies the amount of clearance.

By this concept is meant the inner diameter, rounded to the nearest standard value. A complete list of standard values of DN can be found in GOST 28338-89, the minimum value is 2.5 mm, and the maximum is 4000 mm.

The main confusion arises from the fact that in 99% of cases the actual internal diameter is not equal to the nominal (conditional) one. If, for example, we take the standard water-gas metal pipe with an outer dimension of 159 mm, then the actual size of the gap will depend on the wall thickness. So, with a metal thickness of 6 mm, it will be equal to 147 mm, and with an 8-mm wall - 143 mm.

But if you look at the values given in the standard, it turns out that the same nominal diameter - DN150 (or DN150) - is suitable for both of these cases. The same principle also works with smaller sizes; this should be taken into account when selecting valves. For example, a ball valve DN 20 has a nominal size of 20 mm, which means it is suitable only for installation on a pipe with a corresponding diameter.

Note! At first glance, such a notation looks ridiculous, but it is not. In fact, the step between the standard values is adopted such that the throughput of each next lumen value increases by about 60-70%. This facilitates the selection of the pipeline at the stage of calculation of water, gas and heat pipelines.

Device, selection and installation of ball valve

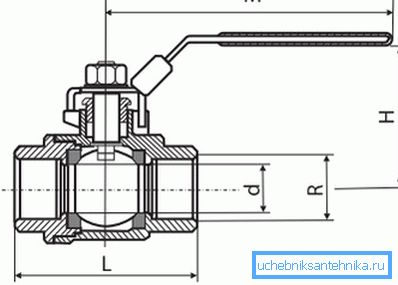

As for the structure of such a device, it does not change depending on the size. Unless sometimes, instead of a knob, an electric drive is installed to turn the ball, it is necessary when a large knob cannot simply be turned due to lack of free space.

What to look for when choosing

Another difficulty in the selection of a specific model of a ball valve can be the conversion of inch sizes to metric and the selection of the appropriate value of DN (DN). For example, a DN20 ball valve is suitable for installation on a VGP pipe with an outer diameter of 26.8 mm, with the thread size being equal? in.

Correspondence of inch sizes of thread, DN and external size of the pipe is given in the table.

The correspondence between the conditional passage and the outer diameter of the pipe

| Measured diameter of AIV pipe, mm | Diameter of steel pipe, mm | PEX - cross-linked polyethylene, metal-plastic pipes, mm | Pipes from the reinforced software (PPR a20), mm | Polypropylene pipe PP20, mm | PP pipe PP16, mm | Nominal diameter, it is conditional passage (DN or DN), mm | Thread diameter |

| 22.0 | 15 | 20 | 20 | 25 | 20 | 15 | 1/2 |

| 28.0 | 20 | 25 | 25 | 32 | 25.32 | 20 | 3/4 |

| 32.0 | 25 | 32 | 32.40 | 40 | 40 | 25 | one |

| 42.0 | 32 | 40 | 40.50 | 50 | 50 | 32 | one ? |

| 50.0 | 40 | 50 | 50.63 | 63 | 63 | 40 | one ? |

| 63.0 | 50 | 63 | 75 | 75 | 75 | 50 | 2 |

Note! The table shows data only for the most common sizes that are used in private construction.

The table shows a significant discrepancy between pipes of different types, even within the same size of valves. This is explained by the different wall thickness of the pipes, as well as by the fact that the internal diameter is indicated in the metal bar, but for plastic products - the external diameter.

And although the price of a simple ball valve is small (simple polypropylene models cost less than 200 rubles), it is still better to immediately pay attention to these subtleties.

Features of polypropylene cranes

Relatively recently, PP ball valves have appeared on the market. In such devices, the design of the locking part remains unchanged - the same metal ball with through holes, but the body is made of polypropylene. In this case, before the number that indicates the amount of clearance, followed by an abbreviation denoting the type of material used.

For example, the entry PPRC 20 ball valve means that the body is made of type 3 polypropylene (random copolymer), and the nominal diameter is 20 mm.

Note! For installation of a conventional model with a metal housing, detachable connections are usually used. In the case of PP analogue it makes sense to use the connection by soldering.

Installation instructions is no different from the connection of conventional PP pipes:

- A special “soldering iron” is used for the connection.. The heating element of such a device is designed in such a way that it is possible to put on tubes of different diameters. The faucet and pipe are put on the heating element and heated up for a short time;

- after that you need to quickly remove both elements from the soldering iron and insert the end of the tube into the faucet. If the polypropylene is warmed up sufficiently, then part of it should simply be squeezed out during installation, this is normal.

The above connection is considered the simplest, but it is not without flaws. The main can be considered the occurrence of significant local resistance. If, for example, a ball valve PP 20 with a pipe, then the pipe Du will be equal to only 15 mm, and in the crane - 20 mm.

Accordingly, when the flow passes through the joint, due to the difference in diameters, turbulence will be created at the inlet, and an increased load on the weld will be generated at the outlet.

This can be avoided in 2 ways:

- using a detachable connection, for example, the same American;

- using the PP coupling, in this case, you can use welding. Using a coupling will allow you to connect the pipe and faucet end-to-end, so that nothing will interfere with the flow. None of these methods complicates the process itself, so the installation can be done by hand.

Summarizing

Selection of a ball valve is not such an easy task as it may seem at first glance. You need to clearly understand the difference between such concepts as nominal and real diameters, to be able to convert metric dimensions to inch and vice versa.

The proposed information will not confuse the designation of valves and control valves and ensures the correct choice. The video in this article is a short overview of different types of ball valves.