Decorative cover on the well: purpose, types and self-design

Modern wells in the summer cottage allow a person not only to receive the purest drinking water, which can now be delivered to the house with the help of pumping equipment by running water, but also, when designed in a certain style, can also serve as a decoration for the landscape, giving it a special personality.

An indispensable part of such tanks is the well cover, which has more than one important purpose.

Well cover functions

In order for the dacha reservoir to look aesthetically and beautifully, decorative covers for wells are made either from a similar or from the same material as the well itself. (See also the article Features plastic cover for the well.)

But such products are not only decoration design, but also perform the following functions:

- protect the well from insects, birds, small animals, debris, chemicals and so on;

- protect water from freezing in winter;

- allow the water to stay cool in hot weather.

For all these reasons, decorative covers for the well must have good strength properties and tightly fixed on the well. In addition, in order to make such a protective device easier to use, it should not be made of heavy materials.

In this regard, many people may have more than one question: what are such products made of? Can it be done with your own hands? All this, as well as other, no less important things, will be discussed further.

Types of well covers for design features

Decorative covers for wells are not any complicated products in their device, so any adult can do them with their own hands. However, before choosing a material for them and starting to manufacture them, you should be aware that they are not completely removable or fixed to the work with the help of hinges..

In addition, they are divided into one-piece and two-fold structures. Which model to give preference will depend on the tastes of the owner of the site, and often on the characteristics of the well itself.

Popular types of caps for the manufacture of materials and the process of self-creation of some of them

Wood products

Decorative cover for the well, made of wood is considered the most popular product, because with the help of this material you can create various patterns or ornaments, thereby achieving very beautiful results. But even if the tree is simply varnished, then such a product will also look no less attractive.

In addition, the tree - an environmentally friendly material, and this is very important, because the hatch from it will be used for the well, in which there is drinking water. An important advantage is also the fact that such a product will not have much weight, therefore, it will be quite easy to open or close the well.

Note! Since wood absorbs moisture well, any instructions for working with this material state that products made of wood that are planned to be used in the external environment must be covered with water-repellent solutions. This will prevent the cover from rotting and prolong its service life as a whole.

It is possible to make a wooden well protective object from aspen, oak, elm, birch. To do this, you first need to decide on the size and shape of this product. These parameters will directly depend on the type and well mouth.

The simplest product is the type of hatch.

For the manufacture of such devices will need the following materials and tools:

- hinges (if you plan to make the cover flip, not removable);

- nails or screws;

- dried hewn boards (preferably with grooves);

- pens;

- wooden bars;

- hammer;

- roulette;

- hacksaw for wood;

- screwdriver;

- rubber belt.

At the first stage, on the upper and lower parts of the work, you should install a crate from a wide beam. This is necessary so that the protector has something to hold on to.

Further, with the help of nails and screws, hewn boards are fixed between themselves, pre-cut to the required size. It should be ensured that the docking of the grooves occurs without gaps.

In the very center of the product you can fix the reinforcing wooden beam. Then handles are screwed on it, without which it will be much more difficult to use this device.

At the last stage, it is attached to the crate with the help of loops. They can be replaced with a rubber belt. In this case, one end of it is attached to the creation, and the other - to the cover.

Note! If in the region where the site with the well is located, in winter the temperature drops to -10 degrees and below, you will definitely need to make not one, but two identical covers. The second product will be needed in order to have the opportunity to put a layer of straw between them, which will serve as insulation. Such a dual device will help prevent freezing of water in the tank.

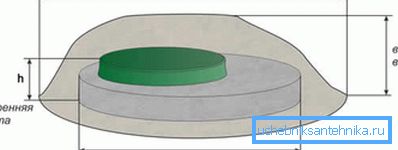

Well products in the form of a natural stone

If the well on the site does not rise high above the ground level, is decorated with natural stone or it is made of concrete rings, then the cover under the stone will be the best protective option for such a reservoir. Such products are manufactured ready-made in various size variations from modern materials, thanks to which they have a very light weight.

Moreover, the price of such covers is affordable for almost every person. Their cost starts from 3,000 rubles, and if for any reason it is not possible to make a hatch for a well with your own hands, then, having bought such a product, the site owner can get rid of unnecessary trouble.

Products from metal corners

For lovers of tinkering with their own hands, there is another good idea to make a well cover - it can be made from metal corners and PCB.

To do this, you will need to stock up on the following items:

- metal corners;

- textolite;

- pens;

- hinges;

- sealant;

- cement;

- Bulgarian;

- self-tapping screws;

- screwdriver;

- hammer;

- boards for crates;

- welding machine;

- roulette.

The process of making a cover from metal corners consists of the following steps:

- At first, measurements were made and, focusing on them, 4 blanks were cut from a metal corner of a slightly larger size than the sides of the well. Moreover, their angles should have 45 degrees.

- Further, all segments need to be welded into a quadrangle. In order for the frame to be strong, the corners should be welded both from the inside and from the outside. After work is finished, traces of welding can be removed with the help of a grinder.

- After that, plates are cut from PCB. They are attached to each other with screws. In this case, you should not forget to lay a layer of insulation between the plates, and you will definitely need to treat all seams with a sealant.

- Next, formwork is installed around the perimeter of the tank, the frame is laid and a concrete solution is poured into the voids.

- Next, the finished cover should be attached to the frame with loops.

- At the last stage, the handles for the cover are installed; if necessary, the surface is painted or decorated in any other way. (See also the article Cover for a well - how to install it yourself.)

Conclusion

Of course, there are still many options for the manufacture of well covers, because of human imagination there is no limit. Watch the video in this article, and perhaps you will find more than one original solution for constructing and decorating this indispensable and very useful protective device.