Do-it-yourself well-built log house - rules and technology

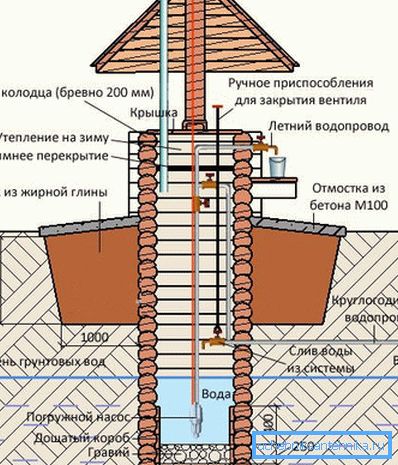

Practically at any country site it is possible to make a well, which with its water can fully satisfy the needs of the owners. In order for it to stand for a long time, it is necessary to strengthen its walls, as well as to protect the tip from possible entry of debris, dust and dirt.

You can do this with the help of concrete rings, but often the owners of the source want a well-wooden blockhouse, which can be made by hand.

Prepare materials and tools

- Sand and granite rubble for the drainage layer;

- Logs or timber in the right quantity;

- Clay, if needed;

- Fasteners;

- Shovels, buckets.

The tree is a natural material and quite popular in the construction of country houses, baths and other buildings. After some time of living in a gassed urban atmosphere, you want to break out into the fresh air and be surrounded by natural things. Therefore, the article will talk about how to make a log cabin for the well with your own hands without high costs..

A log house for the well will complement the landscape of the site where there are already other wooden buildings. Water is the main element outside the city, without which existence here is simply impossible.

Tip: before you buy a site, carefully check its ability to connect not only to the central conduit, but also the level of groundwater on it.

If you take the technical side, a log house on the well with your own hands looks a little different than, for example, a bathhouse log house, since its main part is located underground, which imposes its difficulties. Work will occur at a depth that is directly dependent on the aquifer.

It should be understood that if the mine is too shallow, it means that there will be no water from the aquifers in the well, but a water pipe that does not differ in purity, therefore it is unsuitable for drinking. Prepare in advance for what will have to fall to a depth of 15 m and more.

When choosing a place for the source of drinking water, make sure that there are no compost heaps, garbage dumps and waste water. It is also advisable to determine in advance the possible depth of the aquifer in order to prepare the necessary amount of material.

Tip: ask your neighbors or invite a specialist familiar with the geology of the region.

Security

- Digging a well is a laborious and dangerous job, so it’s better not to do it alone, so that there is always an insurer at the top. The width of the mine should be about 1.5 m, so it will be easier to dig.

- From the bottom, lift the ground with a bucket tied to a winch cable or something similar, while working below should have a construction helmet on your head. From time to time it is necessary to climb up from the shaft to breathe air, and the volume of oxygen in the pit can be checked by lighted candles.

- Be especially careful when reaching a depth of 5-6 meters, since now you have to work only with safety net. The helper should observe working at depth and when signs of weakness, suffocation, nausea, or dizziness appear, immediately evacuate him.

- The most difficult stage is the opening of the aquifer. From this point on, water begins to flow into the well, and the earth turns into slime. From this point on, it is necessary to use a submersible pump that can quickly remove water from under your feet so that the shaft does not collapse. Before starting work in water, it is necessary to disinfect boots and tools with a chlorine solution so as not to introduce pathogens. Punching the aquifer should be at least one meter.

Well Log House

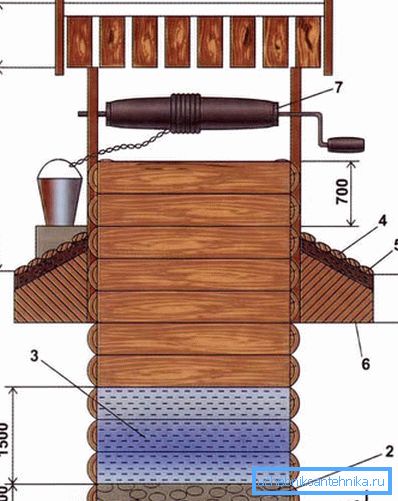

At the first stage, determine its height and horizontal section. Add to the first parameter another half a meter to the top of the well. (See also the article Tophole Features.)

The lower part of the building, the sunbeds and planks must be made of oak. The middle and top are made of birch, linden or alder.

Be careful about the choice of wood, it should be dry, do not have signs of rot (blue), as well as bark beetles. Such requirements are necessary because the tree from which the log cabins are made with their own hands will constantly be in contact with water, therefore such conditions are akin to extreme.

A well-dried material will swell from moisture and cover any possible gaps. Therefore, for such purposes, and selected oak, wood which is considered the most durable.

However, there is a nuance here as well, due to the fact that within a year or two it will release tannins into well water, which will make it unsuitable for drinking. The problem is solved by pre-soaking for about 2-3 years in water, and then drying it in spring and summer under a canopy. After this treatment, the material serves more than half a century. If you do everything yourself, its price will not be big for you.

This procedure is called “staring” and is carried out in a natural source of running water, for example, in a river. The process can be done independently, only having learned some details.

Here the principle is applied - the longer the logs are in the water, the higher the quality. During this treatment, the wood will lose its tannins, dyeing the water brown and adding a bitter taste to it. In addition, after staining the material becomes even stronger.

The instruction looks like this:

- Choose logs, peel them from bark and knots. Do not scrape the top layer of logs, destroying their protective layer.

- Cut the material after processing to the desired size.

- Collect the log house on the surface and number each log. It happens that the depth of the well is large, so the process will be quite difficult or even impossible. Then make the assembly in parts, for example, 2 m in height.

- In the next step, dismantle the log house and drown the logs in running water for 1-2 years.

- After the expiration of the wet, pull the logs to the surface, stack them in piles under the canopy. The place should be well protected from sunlight and drafts.

- Having thoroughly dried the logs, begin to proceed to the preparation of the assembly of the well according to the previously made marking.

Pine, cedar and larch do not affect the water and are well tolerated by moisture, their service life is about 30 years. Ash, beech and elm do not spoil the taste of water and they can persist in it for a long time, and the upper part of these materials quickly becomes unusable, rotting.

Tip: it is advisable to collect from the bottom of the logs of such species, and the upper part of coniferous wood or oak.

Logs for well logs

- Without bark, with intact diameter;

- No rot and dust, no insects;

- Logs should have a diameter of 180-200 mm, with a deviation of no more than 10 mm per meter length;

- They should not stain the water in the well and give it a foreign taste;

- It is forbidden to treat logs with antiseptics and other chemical compounds.

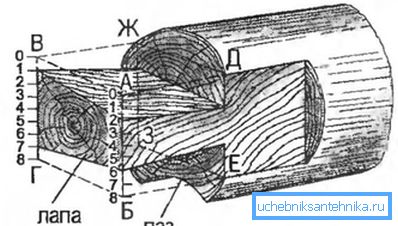

Felling should be collected from pre-prepared logs. They should be chopped for fastening the rims, and longitudinal grooves - for a better fit.

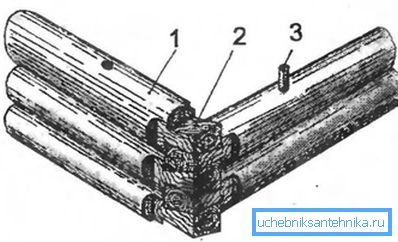

It is necessary that the crown of the logs tightly adjoined to each other, and the side that faces the inside of the well should be cut to the plane. For the strength of the crowns connect the rectangular or round spikes. Mark the logs, make grooves on both sides, to which the other bars are fitted.

The cutting is traditionally done “in the paw” or “in the half-tree”. You should not take up the first option if you do not have the skills of a carpenter. To join the timber in the "half-wood" use shkanty.

Installing a log house

Above, we learned everything that we need to install a well-built log house, so it is time to start creating it.

It is more convenient to assemble it on the ground, and then install it in a mine with a lifting device or with an assistant.

- Remove all the water from the well, remove about 150 mm from the bottom of the well, level it and compact it. You can do the following: lay the walls of the hole with a brick, put a layer of rubble or sand on the bottom to clean the water. First large river sand, then fine gravel, and finish with a layer of large rubble 150-200 mm high. Pre-gravel and rubble should be washed in bleach, and then in clean water. At the bottom, the drainage layer performs two functions - it filters the water in the well and prevents scum from entering the dregs in the bucket.

- Install a log house in the mine so that its lower part is below the water horizon. At the same time, in order to avoid deformation of the structure when lowering, nail temporarily the boards to the crowns. Carry out the process carefully to avoid strong sprinkling of the walls inside the mine. In the place of installation of the lower crown of the log house, cover the niches and install wooden supports from the remnants of the logs in them, and then lower the frame on them. For a better fit, lay down a log cabin with a heavy sledge hammer on the upper rims.

- Now clean the soil under the other parts of the lower crown. Make a hole in the middle in order to clean it there during the upsetting. Remove the support from under the rims so that the log house is firmly seated on the bottom, and if anything, help him with a sledgehammer. Repeat the process further, building up the structure of the parts assembled on the surface. Continue until the log house is fully lowered. It happens that he is very tightly stuck in the mine, so there is no way to lower it further, then you have to build up the crowns from top to bottom. Do this by undermining the ground and installing new logs from below.

- When there is a large accumulation of water in the pit and its depth reaches the aquifer, the assembly should be stopped. It is necessary to drain the shaft with a submersible pump or buckets. Only then can the next crown be made. (See also the article How to choose a pump for a well: selection criteria)

If this does not give a result, but it is necessary to reach the desired depth of the well, make the lowest crown of slightly elongated logs, 500-600 mm, which are called pledges. They are needed as supporting elements that hold the frame and do not allow it to go down.

Dip a box of thick planks into it, which you face up to until it reaches the bottom border, taking into account the filling of sand and gravel on the bottom. For the plant pledges for the log house, you must select the appropriate niche in the mine. The space remaining between the frame and the pit, covered with earth.

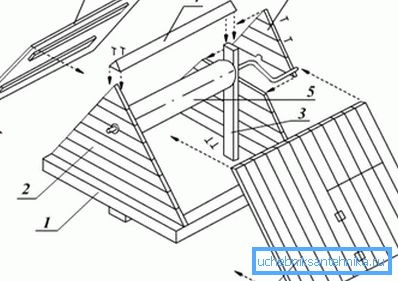

- Make a blind area for the ground part of clay and concrete. Cover it with a gable tent of planks covering a 400 mm shaft to protect it from rainwater. Install above the barrel of the gate to understand the bucket when there is no electricity.

Tip: Install the locking device on the well cover so that children or animals do not fall into it.

After completion of the work with the log house, all the water from the well must be pumped out. Moreover, it should be done preferably for 1-2 weeks, using it as a technical one. After that, collect water for the sample in a clean dish and take it to the laboratory for a comprehensive quality analysis.

Conclusion

Making a wooden house is a long and laborious work that can last more than one year, if you consider the staining of wood. As for the rest, it does not differ from the assembly of an ordinary log house, although there are, of course, nuances for its installation in the mine. In the presented video in this article you will find additional information on this topic.