Do-it-yourself well drainage - talk essentially

The key element of the drainage system is a well, now we will discuss what kind of wells there are and how to make a drainage well with your own hands with an acceptable price-performance ratio.

Types of designs

In general, all such structures are a container, dug into the ground, having a bottom, a cover, inlet and outlet pipes.. This capacity, depending on the destination, is laid at different depths and has a different diameter. There are several main types of designs.

Swivel structures

- This view is the simplest. Such containers are ideally installed at every turn of the system. But placement through one turn is allowed.

- Pipes in them must be disconnected in order to have access to the system for cleaning if necessary. The diameter of such wells varies in the region of 30 - 40 cm.

Viewing structures

A manhole, in fact, is a more functional version of a rotary well. The difference is that several pipes of the system converge into it, such constructions play the role of distribution nodes.

In large drainage systems they are made in such a way that it is possible to climb into them, for inspection and repair work, for an adult. In drains of small volume, their size may not exceed the size of a rotary well.

Accumulation systems

- Storage tanks are installed in places where it is not possible to divert the water collected by the drainage system to the sewage system or simply outside the site. As a rule, these are rather large tanks with a diameter of up to 1.5 m and having different depths. As they are filled, water is pumped out by the pump and removed from the site or used for irrigation.

- Such containers are often equipped with elementary automation. A float is installed, which, when the tank is filled to a certain level, closes the circuit and starts the pump for pumping.

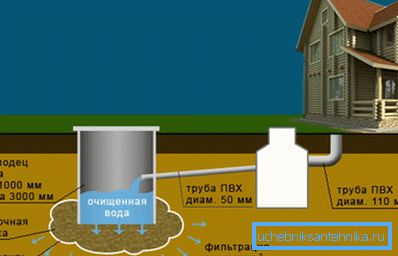

Filtration systems or septic tanks

The name here speaks for itself; these are rather large wells with a depth of at least 2 m. They do not have a sealed bottom; instead, a natural filter made of gravel, sand or any similar material of different fraction is installed at the bottom of the well. Drains are cleaned by passing through such a filter, and then go to the depth. Such designs are very effective on sandy soil.

Important: some adventurous hosts use a serial connection. Water from the drainage enters the reservoir, which at the top point has a conclusion to the filtration septic tank or sewage system. Thus, on the site there is always a tank with water for irrigation, which will never overflow.

Arrangement technology

- For the arrangement of the drainage system are used reinforced concrete or plastic structures. The principle of the system itself is simple, starting from the top of the site, to a certain depth, on a slope of 20 to 50 mm for 2 meters of linear, perforated pipes for collecting groundwater are laid. When turning and in the nodal joints, turning or viewing wells settle.

- The entire system is assembled into a single node, which is crowned with a drainage or storage well. From it the collected water is removed in a forced or natural way. Drainage wells with their own hands do quite real, concrete structures are quite reliable and the price is affordable, but they are bulky and heavy.

- Plastic products are light and comfortable, they are quickly and easily mounted, but the price of plastic wells, especially large diameter, is high. Therefore, many people prefer turning and viewing wells to make plastic, and the drainage well for a septic tank to do with concrete with their own hands.

Important: regardless of what well will be installed, the pipes for the system, we advise, use only plastic. They are more durable, up to 50 years, plus they are light and not expensive.

Use of concrete rings

- The device of a drainage well with its own hands from concrete rings alone is practically unreal. At a minimum, you will need the help of 1 more person. Special equipment is needed to deliver the rings to the site, then you can do it yourself, the rings can be simply rolled to the right place.

- The drainage well for a septic tank is laid with its own hands to a depth of 2 - 3 m. The cumulative structure is also buried at about the same depth. At the tab, you can act in 2 ways, the instruction in both cases is simple.

- For the first option, the top layer of the soil is removed, according to the size of the ring, then a ring is inserted into it, and then, from the inside, you begin to deepen. As you deepen, the ring will drop under its own weight. Having reached the ground level, the next ring is placed on it and sealed with metal brackets. So you go deep and grow to the right depth. Rings, from the outside should be waterproofed.

- The second option, from our point of view, is safer and a bit simpler. Initially, the excavation is dug 30–40 cm larger than the diameter of the rings. If the bottom is soft, then a gravel pad is filled 150 to 200 mm from the base. After that, the rings are alternately discarded and fastened with brackets. The outer side is waterproofed.

- The space between the ring and the wall of the mine is 50 cm up, covered with rubble. Further, all the space, to the top, is filled up and compacted with clay. The result is a clay castle, which will be a reliable protection from groundwater and this mine will serve for a long time.

- At the bottom of the mine layers of sand, fine gravel and crushed stone are poured. The total size of the filter should be at least 350 mm. The joints of the rings are covered with a cement-sand mortar using waterproof cement.

- If a storage tank is planned, then after the rings are installed, a pad of sand with gravel is poured at the bottom, a reinforcing frame is mounted and concrete is poured. The reinforcement cage should fit into the holes specially drilled around the perimeter of the ring.

Plastic option

- The device of a drainage well with the hands from plastic is much easier and simpler. Initially, a hole of the required depth is digging, at the bottom of the mine a cushion of sand and gravel is made and a reinforced concrete sole is poured. The shaft should be slightly larger than the diameter of the well. The remaining space is filled with sand or rubble.

- For small drainage systems, inspection and rotary wells can be made independently of a plastic pipe with a diameter of 340 mm, up to 460 mm.

- For joining pipes used rubber gaskets. If the well is made of plastic pipe, the bottom can be sealed with bitumen or glued and lubricated with sealants.

- At each well there should be a hermetically closed lid; the neck of the structure can rise 100 mm above the ground level. If the system becomes clogged, it is recommended to punch it with the help of a large water pressure. (See also the article Features plastic cover for the well.)

The video in this article shows the arrangement of the system in a private house.

Conclusion

Our instruction does not claim to be the ultimate truth. We just outlined one of the options for arranging the system with minimal cost. If funds allow, then naturally, it is better to purchase a centralized factory plastic system.