Downhole submersible pump features selection and operation

Along with surface-acting pumps, there are submersible borehole pumps. What are the features of the choice of this equipment, and what are the features of its operation? Surely, the answer to these questions will interest the owners of country houses and suburban plots who do not have access to a centralized water supply.

Despite the fact that the price of submersible pumps is high, they fully justify the funds invested in their purchase. Such equipment allows for the withdrawal of water from large depths in comparison with pumping installations of other modifications. The depth from which you can pump out water can reach 300 meters.

However, such equipment has a significant drawback - this is the complexity of maintenance and low maintainability.

Construction features

A submersible borehole pump is distinguished by the presence of a strong hermetic casing, which is necessary to protect the mechanism from corrosion.

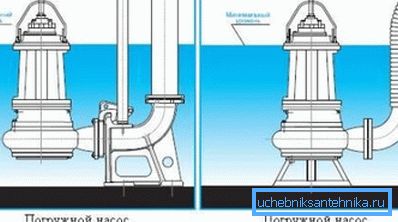

This equipment is divided into two main groups: vibratory and submersible centrifugal downhole pump.

- Vibration plants inject water through vibrations produced with a certain amplitude. For this reason, such equipment should be located at a considerable distance from the sandy bottom.

This is because the impact of vibrations on the internal surfaces of the well will lead to turbidity and water pollution by suspended particles of soil. As a result, it will be necessary to invest additional funds in the multi-stage purification of produced water from the well.

- Submersible centrifugal borehole pump pumps water through the rotation of the wheel, equipped with blades. The wheel is located in the internal volume of the device.

In the process of rotating the blades, a centrifugal force is created, which with a force throws water onto the pump walls. As a result, water under pressure enters the output of the device.

Classification in accordance with the scope of

Submersible pumps, depending on the design features, can be used to perform a variety of tasks.

The following categories of submersible pumps can be distinguished from the equipment on the market: well or water, borehole, drainage and fecal.

- Water pumps or, as they are also called, submersible well pumps are devices adapted for pumping water without significant impurities of suspended solid abrasive particles.

Water should not contain such impurities as sand, silt, algae, etc. Therefore, the working part of the equipment should be located not less than a meter from the bottom of the sump. Such plants are equally suitable for pumping drinking or process water.

The modern well pump is a wide range of modifications adapted for work, both at full, and at partial immersion. Such versatility is achieved due to the lower location of the water inlet.

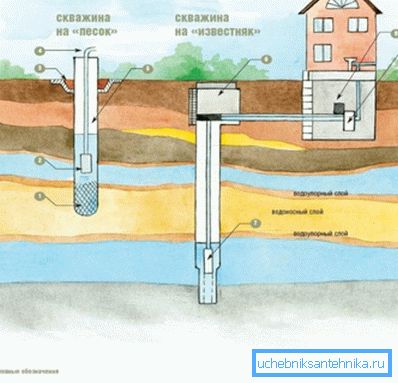

- Downhole submersible pumps are used to supply water from a depth of up to 300 meters. Equipment of this type is adapted for pumping water with a high level of salinity.

For example, thanks to some constructive solutions, plants pumped water with suspended particles of lime and sand without negative consequences for working capacity.

Equipment of this type is immersed in wells of limited diameter. This property explains the specific shape of the pumps, they are all oblong cylindrical in shape.

Despite the shape and compact dimensions, these devices are characterized by high power, which is sufficient to provide water to both a small country house and a complex of several housing estates.

An important advantage of downhole pumps is that water is not only pumped, but also cools the engine at the same time. As a result, the engine resource increases significantly. The float switch, which is equipped with a pump, provides automatic shutdown of the device if a sharp drop in water level occurs.

The only drawback of these devices is the complexity of installation and repair, as well as the high cost.

- A submersible drainage pump can be used for pumping wastewater and melt water with an average value of suspended solids. The pump with equal success overtakes a liquid medium with a high content of sand, algae and small debris that passes through the drainage grids.

Equipment of this type allows you to pump water from the ditch for the subsequent irrigation of the garden. In addition, using this installation, you can pump out the water that has accumulated in the basement or cellar. If necessary, this type of submersible pumps can be used for pumping water from open reservoirs and for replacing water in the pool.

- Fecal submersible pumps are a separate category of equipment adapted to transport sewage. Such plants are able to work with the largest solid contaminants.

In order to pass larger contaminants, the fecal pump, unlike the drainage counterpart, is equipped not with filters, but with a grinder in the form of a cutting nozzle.

This type of equipment is the best solution when there is no possibility to equip an effective system of gravity drainage of sewage water. The advantage of fecal submersible pumps is that they do not need to be regularly removed from the pit, as they operate for a long time without the need for maintenance.

Features of the choice of a submersible pump

The instruction of choosing a domestic submersible pump is not a big deal, you just have to pay attention to a number of factors.

- Performance and pressure head, which can provide equipment - these are parameters that deserve special attention. Regardless of the purpose for which you choose the pump, you need to compare its capacity and performance with the parameters of pumping a liquid medium. In order to calculate the performance, it is necessary to determine the maximum consumption. According to SNiP, water consumption per day is from 150 to 200 liters per person. At the same time, watering a square meter of a summer cottage requires up to 6 liters of water daily. Calculate the pressure, you can considering the height of the water rise and the length of the horizontal path of its passage.

- Price is an equally important parameter when choosing household equipment. The acquisition cost should be motivated by build quality, performance, efficiency and availability of warranty service.

- The level of automation is the characteristic that will provide operational comfort for everyday use of the pump.

- Brand manufacturer is, of course, not the most important factor when choosing submersible pumps, but it is this criterion that forms the cost of equipment.

Overview of the largest manufacturers of submersible pumps

- Under the Awelco trademark, high-tech and at the same time reliable Italian submersible pumps of the water and well type are presented. Despite overseas production and high build quality, the installations differ from this manufacturer at affordable prices. In the world market, the company's products have been successfully sold for more than 20 years.

- The German company Al-co has been manufacturing pumping equipment for more than 70 years and today these devices are available in the post-Soviet space. Among the wide range of pumps of this brand, you can choose the option that is most suitable for the needs of your country house or suburban area.

- Perhaps the most famous and popular manufacturer of submersible pumps is the Danish company Grundfos. This brand produces high-quality and reliable devices. The company manufactures the entire range of submersible pumping equipment and provides users with the highest quality technical support.

- The German company Wilo is another manufacturer of borehole pumps, whose products are becoming increasingly popular in the CIS countries. The equipment of the brand is distinguished by reliability in combination with economical energy consumption.

- The company "Dzhileks" - is a major Russian manufacturer of submersible pumps. Brand products are sold in the domestic market for over 20 years. It should be noted that the latest developments, despite the reasonable price, are in no way inferior to foreign analogues.

Installation of the borehole pump

After the equipment that matches the parameters of the well and your capabilities is selected, it's time to start the installation.

Important: Submersible pumps, certified for sale and operation in the territory of the Russian Federation, are completed with a user manual, where the requirements for installation are described in detail.

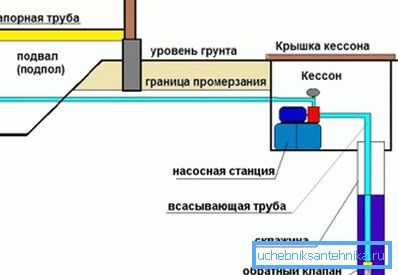

Before the installation, it is necessary to lay the water supply from the house to the caisson. Laying of water supply for all-season operation should be carried out taking into account the depth of soil freezing. Thus, the pipe should lie no higher than at a half meter depth.

Before proceeding with the installation of a well pump, we thoroughly clean the well and pump it using airlift. Then we pump out the water until the well is completely free from contamination.

As already mentioned, the device is immersed in the well below the surface of the water, but at a distance of at least a meter from the bottom. The distance to the bottom is necessary so that when pumping with water, do not lift sedimentary soil, sand and silt to the surface.

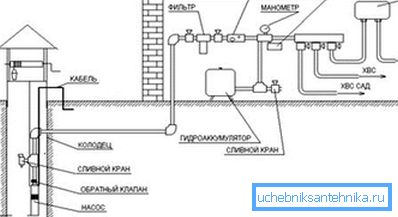

With a pump, a production plastic pipe necessary for lifting water, a power cable and a safety wire are lowered into the well. Power is supplied to the pump motor via a protected power cable.

Important: When a submersible pump fails, first of all, the cable sheath is checked for damage.

The safety cable is mounted on the top of the well and keeps the entire structure in limbo. The pipe through which water is pumped is supplied directly to the house or to a storage tank.

An important structural element is the cap used to seal the upper part of the well. Eyebolts and through holes for hummock, cable and pipe are provided in the tip.

During installation, it is necessary to provide a check valve device to protect the operating system from the damaging effects of water hammer. If the manufacturer does not provide for the presence of a check valve in the equipment, you can avoid backflow of water by installing a valve after installing the pump.

Having finished the preparatory work it is necessary to adjust the pressure in the pressure tank with your own hands. The calculated pressure value must be at least 0.9 units of the pressure at start-up.

After installing the check valve, the pump can be lowered into the well and proceed to the installation of the start-up device. The connection scheme of a submersible borehole pump for each individual device may have its own distinctive features. Therefore, installation work must be coordinated in accordance with the instructions.

Regardless of what the parameters of the selected pump, installing this equipment, it is necessary to align the point of work in different modes. In addition, you will need to measure the estimated flow rate of the water supply. This parameter is determined according to the speed of filling the volume. The created pressure is measured by a pressure gauge, and the current consumption can be measured with special current tongs.

In that case, if the parameters of the well pump are exceeded in comparison with the nominal characteristics specified by the manufacturer, at the outlet of the well it is necessary to close the pump valve. As a result, a resistance will be created that is sufficient in order to properly set the operating point.

Important: When installing a downhole pump, it is necessary to equip it with a starter with protection and adjust it in accordance with the calculated current value.

Conclusion

Installing a submersible pump in the well is not as difficult as it may seem. The main thing is to strictly observe the recommendations of the manufacturer and to choose the right pumping equipment. To make installation work less complicated, watch the video in this article.