Downhole - what is it and how to fight it

The process of drilling a well for water is theoretically simple, but in practice it is quite hard work. Well, if you go through the upper soft layers, you rest on dense stable layers, it is easy to drill into them. Even if you hit a rock, you can go through it with a crown.

But if a well is caught in the floating zone, this is a serious problem.

Quicksand and its types

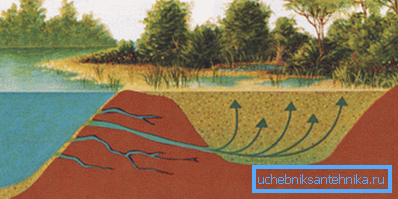

- What is quicksand? Fluke called unstable, water-saturated soil. As a rule, it consists of fine, dusty sandy soils or sandy loams. Also often found wet clay compositions and loams. During mechanical opening of the reservoir, the thickness of which can vary from 2 to 10 m, as a result of a pressure drop, the composition starts to move.

- The problem is that such a layer is extremely unstable, plus there may be patches of small, river pebbles or larger boulders. Its consistency can be pasty or almost liquid, smetannogo type.

- Once in such a layer, it can be scooped for a very long time, there is also a high risk of losing a drill.. But you can fight this trouble. We will talk about how to go through the well in the well later, and now we will deal with what are the quicksands.

Real or real swims

- The composition of such layers are dusty, sandy soils that have a different fraction of particles, as a result of which microscopic particles play the role of lubricant, envelop and bind the whole mass.

- Also in these layers there is a large amount of clay mist, because of which they have a high hydrophobicity. In other words, they bind and reliably hold water. At the opening of the reservoir, a hydraulic shock occurs that drives the fluid mass. Reservoir filtration properties are extremely low, on average 0.5m? per day.

- In the case of freezing such a soil is subject to swelling, if the soil dries, it becomes almost monolithic. There is no consensus about the origin of such layers, but many scientists are prone to the fact that they are formed as a result of the vital activity of some microorganisms.

False flow reservoir

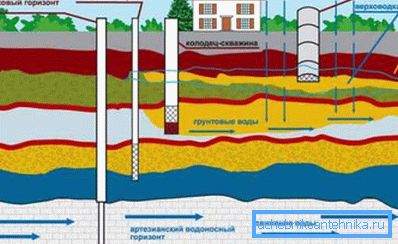

- Sandy, porous formations with a fine fraction of particles strongly saturated with water are called false. They can have a depth of up to 50 m, which is why an overpressure occurs within the formation itself.

- During mechanical opening of the roof, pressure begins to intensively flush fine sand dust into the well. This phenomenon is temporary and with the right approach is quickly eliminated.

Tip: correctly determine what kind of flooded they got, only a specialist can. For amateurs, before starting to do it yourself, you can consult with your neighbors in the area who already have a well, or it is better to contact local geological exploration.

Options for dealing with this nuisance

- Initially, it should be noted that if you know for sure that you have a layer of real, real quicksand present at the site, then we strongly advise you not to start digging a well. Because as reliable, long-term methods of dealing with this nuisance, in conditions of the well, does not exist yet, only a well is suitable for you.

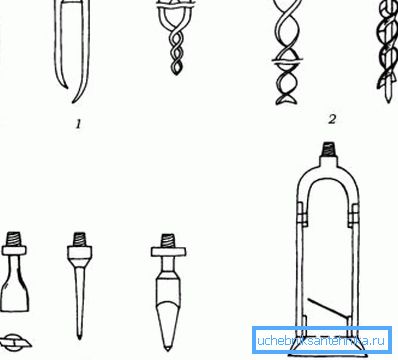

Tip: if you started digging a well and, going deeper to a certain depth, you found a real float, as an option, the well in the well at the float could save you. It can be made according to the principle of the “Abyssinian well” or in any other way suitable for you.

- Instructions for the construction of the well "Abyssinian well" is extremely simple. In a nutshell: a metal pipe with a cone and a filter column at the end is taken, strictly vertically directed into the ground and heavy metal “grandma” is driven to the level of the aquifer. But so you can go a maximum of 20 m, provided a stable soft ground.

- There are two main ways of how to get rid of flooding in the well. Immediately we warn you that both of them are quite laborious and if you are not confident in your abilities, we do not advise you to do the work yourself, turn to specialists. The price of work will rise, but you are guaranteed to equip your well.

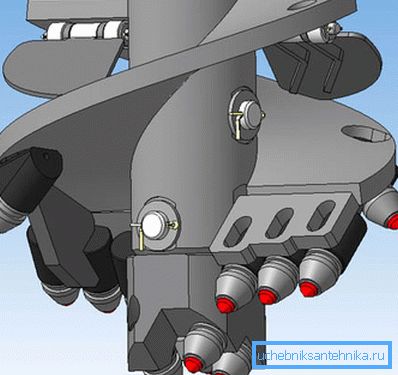

Casing method

- In order that the liquid rock does not flood the well, a parallel casing method is used. The essence of the method is that immediately behind the drill a casing tube is lowered into the well. This work is quite time-consuming, since it will be necessary to carefully monitor that the pipe descends smoothly, without touching the drill and at the same time, not lagging behind it.

- The best option here would be to use a folding professional drill, its price is slightly higher, but it will be much less hassle. The diameter of the casing is selected according to the diameter of the drill. Alternatively, the drill can be rented in local geological exploration.

- If the use of a folding professional drill is not your option, then you can use a conventional chisel or auger, but only until the roof is opened with a liquid rock. Next, the casing pipe is lowered into the well, and penetration is carried out by a scaffold with a check valve or a drill-spoon, simultaneously lowering the casing string.

- A very important point in this method is the need to equip a reliable plug from the bottom of the well filtration column. To do this, take a cloth bag, the diameter of the column, it is filled with a mixture of sand with cement brand 300 - 500, in a ratio of 1: 1 kg. The bag is lowered to the bottom of the column and left for 2 to 3 days. During this time, the cement will grab, and you will get a reliable plug.

Use of bentonite

- Bentonite is a free-flowing powder; it gets its name from a field in Benton, which is located in the United States. The powder has a porous structure and, upon contact with water, increases 14 to 16 times, forming a gel-like substance that does not allow water to pass through. Being in a limited space of the well, the substance hardens and concretes the walls of the well.

- The hardness of the bentonite walls is enough for drilling, but later the well must be strengthened with a metal casing. Also, this material, during drilling, works as a lubricant for drilling equipment. They can still strengthen the walls of the pit. (See also article Cementing Well Features.)

Important: having discovered a floating hole in a well, you should immediately abandon the use of currently popular plastic casing lines. Because of the movement of the breed, they simply sommet. Use only metal, as an option, you can insert plastic into the metal casing.

Conclusion

In conclusion, I would like to advise, if you nevertheless decided to drill with your own hands, pay attention to the fact that the floating hole in the well passes slowly and carefully. If you hurry, the walls of the well may collapse and your drilling equipment may be irretrievably lost.

The video in this article shows the drilling process.