Drain valve: description and technical features

The bleeder valve is designed to control the movement of liquids and gases in pipeline structures. With it, you can adjust the work and your own heating system. In this article we will analyze the main features associated with this element.

General provisions

In order to carry out the adjustment of the movement of liquids and gases in the circuit itself or their release to the outside, two types of structures are used:

| Design | Description and Purpose |

| Passing | They are mounted directly into the pipeline itself, for which they have two special connecting pipes. Designed for isolation of individual sections of the system. |

| Trial running | They are equipped with only one connecting pipe and are often installed in tanks or tanks to allow the liquid filling them. |

Household use

So, what is a ball valve with a drain valve used in everyday life?

- Straight construction will allow to block the pipeline section at the time of repair or installation work without necessarily shutting down the entire heating system.

- Trial running - will help eliminate the formation of air traffic jams in the pipeline, which prevent the uniform distribution of heat.

Advice: brass taps for the descent of air STD 7073B do an excellent job with their perfect combination of price and quality. They are also called Mayevsky cranes.

It is also very convenient to use continuous ball valves with an additional trigger mechanism. We will consider them further more closely.

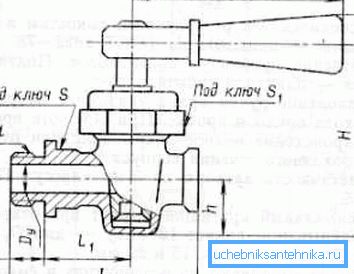

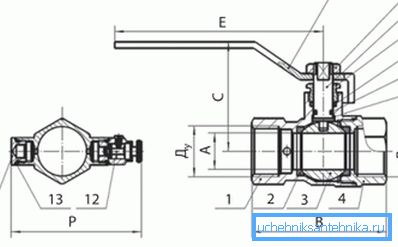

The design of the ball valve with drain valve

| Designation in the figure | Component name | Material |

| one | Body part | Nickel plated brass |

| 2 | Sealing ring | PTFE |

| 3 | Locking ball | Chrome Plated Brass |

| four | Connecting piece | Nickel plated brass |

| five | Packed top end | PTFE |

| 6 | O-ring seal | Rubber |

| 7 | Packed lower stem | PTFE |

| eight | Nut Sealing | Uncoated brass |

| 9 | Stock | Uncoated brass |

| ten | Handle Nut | Steel |

| eleven | Handle | Steel |

| 12 | Drain valve | Brass |

| 13 | Sealing element | Fiber |

Advice: it is recommended to invite professional plumbers to install drain valves, since the instructions for executing this process are quite complicated, and the slightest mistake can lead to depressurization of the entire heating system.

There are samples with a hose nozzle. This greatly simplifies the process of draining the liquid, since using a hose it is easy to direct the flow into a bucket or even a bottle.

Another addition may be the ability to install a pressure gauge that will measure the pressure in the circuit.

Principle of operation

The ball valve with lowering valve functions as follows:

- Turn the handle by hand.

- This movement is transmitted through the rod to the gate.

- The steel ball has a through hole in the middle and is rotated under the action of the rod until it coincides with the outlet of the outlet nozzle.

- The valve also allows you to deflate the air, without setting in motion the entire structure.

Tip: It is recommended to use only the fully open and fully closed position of the handle. If you open the ball only half, then this will lead to rapid wear and breakage of the product.

Although the price of such a device is a little higher than usual, in this case, discharging is much easier. Let's look at the situations in which it needs to be implemented:

When to use a bleed valve

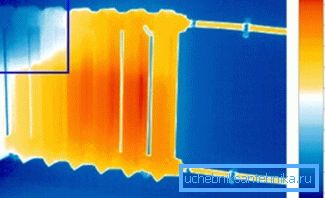

- Primarily after the installation of the heating system. Air will necessarily remain in the pipes of the heating system, and in a closed circuit it cannot go anywhere even under the influence of very high pressure.

- After each summer period, during which the heating was turned off. The fact is that a certain amount of air is necessarily present in the coolants, and for such a long period of lack of circulation, it manages to accumulate in the upper layers of the pipeline.

- Also, the appearance of a plug can be triggered by corrosive processes in which a sufficiently large amount of hydrogen is formed. This is especially true of aluminum radiators, in which, with prolonged contact with the coolant, the described chemical reaction begins.

Conclusion

If you want to be able to control the operation of your heating system, then you need to provide it with a bleeder valve. Besides the fact that it will allow overlapping various compartments of the circuit, it will also enable the removal of air plugs that impede the normal circulation of the coolant.

The video in this article will provide you with additional material that is directly relevant to the topic described. Take care to remove the air plugs in advance.