Drainage pump for a well: features of the device and

Can drainage pumps be used to clean water intake wells? What types of this equipment are on the market? What modification to choose for use in an individual farm?

These and other issues are of considerable interest to the owners of cottages and country houses with an autonomous water supply system. And this is not surprising, since the most inexpensive way to obtain water from the soil is the maintenance of a well. But in order for the operation of the well to be effective, it is necessary to periodically clean the intake shaft, and in this case one cannot do without a pump.

Types of drainage pumps

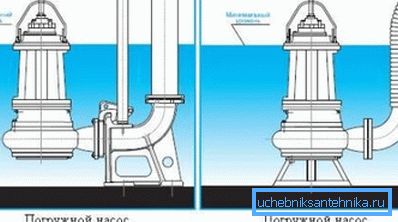

Currently, two types of drainage pumps are distinguished, namely, submersible and surface pumps.

- Submersible drainage pumps for wells work by being lowered to the bottom of the object. By the way of action such devices are divided into vibratory and centrifugal installations. Both equipment is characterized by efficiency, high performance and affordable cost. In addition, if necessary, such devices can be replaced with their own hands.

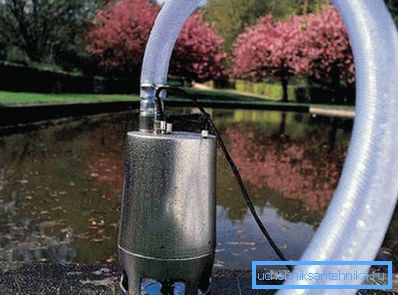

- Surface type pumps are distinguished by the fact that when they are used, only a water pipe or hose is immersed in water.

Among the features of submersible pumps, we note the following advantages:

- small dimensions;

- low weight;

- durability without the need for regular maintenance,

- universality of application, as they can be used for pumping low and medium polluted water,

- high performance (up to 30-40 cubic meters per hour),

- availability of float protection against drainage and, as a result, ease of use;

- possibility of application in the automatic mode in drainage and sewer systems.

Among the shortcomings we note the following:

- the inability to provide strong water pressure when pumping from deep wells;

- impossibility of water purification in the process of pumping, therefore such equipment cannot be used in the system of autonomous water supply.

Surface drainage pump also has its own advantages and disadvantages.

Among the advantages we note:

- powerful pressure, allowing to transport liquid medium over a long distance;

- long operational life due to the device working on the surface, and not in water;

- economical power consumption;

- acceptable price.

However, such equipment has some drawbacks:

- shallow suction depth and, as a result, work in shallow wells (up to 10 meters);

- high noise when operating equipment.

Scope of application

Drainage pumps for a well are devices whose task is to pump out water. The use of such equipment is advisable if the degree of contamination is not the highest.

Also, these devices are widely used in the following situations:

- if necessary, in pumping out water in the course of liquidation of consequences of accidents;

- while eliminating the consequences of excessive groundwater rise;

- when flooding flood waters of the basement and basement premises;

- if necessary, purification of water bodies of artificial origin, such as, for example, pools, tanks of fire hydrants;

- when organizing irrigation according to the method of drip irrigation of areas with small and medium area.

The use of pumps for cleaning wells

Before cleaning the well with a drainage pump, it is necessary to familiarize yourself with the parameters of the equipment, since some modifications of the devices are designed exclusively for pumping clean water. In our case, a modification will be needed that can pump water with various contaminants, namely, fibers and small inclusions..

Important: If the well has not been cleaned for several years, instead of drainage modification of devices, it is advisable to use a fecal pump, which is capable of raising not only water to the surface, but also solid large-sized inclusions.

In order to simplify the cleaning of the water intake shaft, it is advisable to use a pump with a float automatic shutdown mechanism. The float in this case is a switch that is located on the surface of the water. If the float reaches the same level as the pump, the latter is turned off.

This solution will allow you to do without constant monitoring of the process and at the same time avoid overheating of the equipment.

Cleaning the well with a drain pump minimizes the degree of human involvement in the process. After all, a properly configured pump will cope with performing all the work in automatic mode.

Cleaning is carried out as follows:

- The pump is immersed in water so as to be just over a meter to the bottom;

- Turn on the device, and begin pumping clean water. Fresh water will gradually come to the place of pumped water. Due to the movement of the liquid medium, silt deposits at the bottom of the mine collapse and float.

- Further, periodically every few hours, turn off the pump and raise it to the surface. We disassemble the filter and clean the pollution. (See also the article Features of the filter well.)

- Then the device is again lowered into the water, turn on and continue cleaning.

- Cleaning is carried out smoothly until the filter is no longer contaminated.

Important: To maintain cleanliness, the pump can be left at the bottom of the well and periodically every six months to lift it to the surface to clean the filters.

Selection of a drainage pump

The following factors affect the choice of a pump for cleaning a well:

- The location of the suction inlet. It is optimal if the hole is below, since the water is pumped out with almost no residue.

- The case of the device. Industrial equipment is manufactured with cast-iron cases. Undoubtedly, the use of such material ensures reliability, but it is also a lot of weight. Therefore, it is much more appropriate to use pumps with plastic or steel housings.

- Size of the working chamber. This parameter has no special significance when pumping water without impurities. But, if liquids contain large fractions, it is preferable that the size of the working chamber be an order of magnitude larger than their dimensions. Such a characteristic will exclude the possibility of damage to the mechanisms of the unit.

- The complexity of the design. This parameter is desirable to take into account, as a technically complex device is more difficult to maintain and maintain. At the same time, the simpler the pump, the greater the likelihood that it is easy to maintain, maintainable and durable.

Installation and operation of the drainage pump

Drainage pumps are easy to install and use. But in order for the equipment to work efficiently and for a long time, installation must be carried out in accordance with a number of specific rules.

First, unpacking the equipment, you should check its equipment. You also need to familiarize yourself with the instructions of the purchased device, and pay attention to restrictions in the application.

So, the installation instructions are as follows:

- Connect the pressure line (hose or piping) to the pressure connection using connecting clamps.

- If the pumping equipment used is equipped with a float switch and is expected to be used permanently, we install a check valve on the pressure line.

- A device with a three-phase connection must be checked before installation for correctness of the direction of rotation. To do this, install the pump on a flat surface, turn it on and turn it off immediately.

- With the drive stopped, we are looking in which direction the shaft is spinning. Connection is correct if the shaft rotates clockwise. If the rotation is carried out in the opposite direction, reverse the phase.

- Next, the pump is mounted in a vertical position so that the discharge port was directed upwards.

- The finished construction on the cable falls to the bottom of the water intake well.

Conclusion

Now you know how to choose and how to use the intended drain pump. As a rule, there will be no problems with the purchase of the device, since these devices are represented by products of foreign and domestic manufacturers. You just have to decide on the parameters of the well at the dacha and make the right decision.

More interesting and useful information you can find by watching the video in this article.