Drilling a small-sized drilling rig - how to do all the work

As you know, far from all settlements and country associations have a centralized water supply. And in many places where it is, the quality of the water leaves much to be desired, which is why drilling is very common in small-sized drilling rigs. These fairly simple mechanisms will help to make the source independently, without the huge costs of attracting specialists and special equipment. Despite the apparent complexity for the construction of the equipment does not need special tools. A standard set of power tools and some components of the future installation, which are commercially available, are sufficient.

Main types of equipment

It should be understood that mobile drilling rigs for drilling wells are of different types, so you should familiarize yourself with the features of each of them in order to choose the most appropriate type for your conditions.. Consider the most common options.

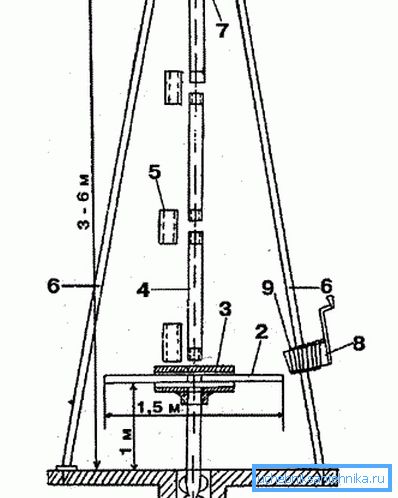

Shock Drilling Equipment

This species has the following features:

- The device is a fairly large and massive frame with a height of about 3 meters.

- The principle of operation is extremely simple: the ground is penetrated by a heavy load, which is made of a sharpened thick-walled pipe. It must be periodically taken to clean the soil.

- Due to the large weight of the load (for effective work it must weigh about 100 kg), it is quite difficult to get it, so you can use an electric winch, not a handheld unit.

Screw type equipment

We can say that this is the most popular installation option due to the fact that the work is much easier and easier. But, at the same time, the design is much more complicated and massive:

- A large and sturdy frame with a wide base is required.

- The main working tool is the auger, which is wrapped in the ground, and then goes to clean the accumulated soil.

- An electric windlass is used to facilitate the lifting of the structure.

How to assemble the equipment yourself

Consider the two most simple varieties, based on which you can make and more high-tech modifications. But, as a rule, an artisanal drilling rig is used 1-2 times with its own hands for drilling wells, so you should not waste money and fully automate the process.

Tip! You should not hurry and buy new units and parts, it is very often possible to purchase parts with wear from organizations engaged in similar work. What is considered worn and is not suitable for professional use, is perfect for the device of a pair of wells.

Percussion drilling equipment

If your choice fell on this system, then the sequence of works will be as follows:

- At first, the construction of the bed is assembled, it should be collapsible, for the convenience of transportation and carrying. The main thing for this part is to provide the necessary strength and resistance to deformation. The most common material for the manufacture of steel pipes.

- Next, you need to make a shock glass, for this fit a thick-walled tube, from one to one and a half meters long and weighing from 80 to 100 kilograms. The lower edge must be sharpened or cut into its teeth, and in the upper part to make several holes for secure attachment of the cartridge to the structure.

- You will also need a scraper, with which the well is cleaned from the ground, it is better to purchase this device in finished form, after all the knot is quite complicated, and it will be very difficult to make it yourself without certain skills.

- To lift the system, use either a block in the upper part of the frame, or (more preferably) an electric winch, securely attached to the frame. The second method greatly simplifies the process, so it is better not to save money and purchase electrical equipment.

The workflow is quite simple: a hole is made in the drill, in which the well will be arranged, at first the ground is broken by a shock glass, and then it is pulled with the help of a scythe. Everything is simple enough, but the process itself is heavy and tedious.

Equipment for auger drilling

Auger drilling rig for wells is a rather popular adaptation option among craftsmen. Therefore, information on the features of manufacturing is sufficiently detailed:

- The first step is to take care of the manufacture of the drill, since it is the main working part. Most often, it is made of a pipe with a diameter of about 10 cm, an external thread is cut in its upper part, and in the lower part a screw with a diameter of about 20 cm is welded, and 3-4 screws are usually enough. To improve entry into the ground, it is better to add a couple of knives on the lower turn of the auger.

- Next, you need to weld a handle to rotate the drill: two handles from 70 centimeters to 1 meter are welded to the metal sleeve, the thread of which corresponds to the thread on the extension sections.

- Also, a sufficient number of extension rods are made, let them be more than necessary, otherwise you risk stopping the work, and not breaking the well to the end.

- The following system is made for lifting the auger: a hole is made in the upper crossbar so that the auger extenders freely pass through. The lifting mechanism can be either manual, with a block in the upper part, or an electric winch - with it the process is greatly simplified.

Drilling a small-sized auger-type drilling rig is a fairly simple process. Using the handles, the drill is wrapped to a depth of 40-50 cm, after which it is reached using a lifting mechanism and cleaned of the soil. If necessary, extension rods are added, and the process continues until the aquifer is reached.

Tip! Before you start drilling, specify the level at which the water stands in the wells of the neighboring areas - this way you will know the approximate depth of the well that you need to reach.

Conclusion

We hope our instruction will help you to make a simple installation for drilling and independently make a well on the site. The video in this article will explain some of the technical points.