Ejector for the pumping station itself

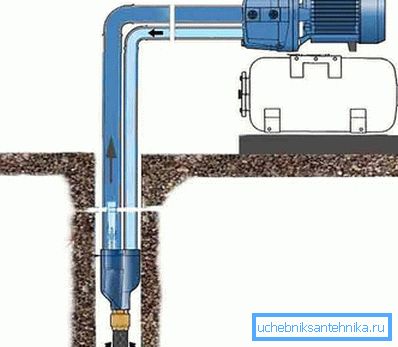

Centrifugal surface pumps are most commonly used to supply water from wells, less often they are used to supply water from a well. The use of this type of pump has a limitation, which is the inability to lift water from a depth of more than 8 m, if the water mirror in the well is below 8 m, then it will not work to lift water with a conventional pump. In order for the pump to raise water from a greater depth, an additional device must be included in the system, which is called an ejector. It is not always possible to find it on sale, and the prices bite, and making an ejector for a pumping station with your own hands from scrap materials is quite realistic. Of course, it will not be as effective as an ejector of industrial production, but it is guaranteed to add about 5 m to the missing depth.

How does an ejector work

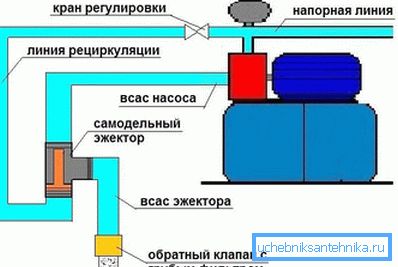

The principle of operation of the ejector is based on the movement of water in the pipe, which, getting into the gently tapering part of the ejector increases its speed, resulting in a zone with reduced pressure, where water is drawn from the outside. The external ejector of the pumping station works by supplying water through a recirculation pipeline; the stream, entering the tapering part, increases the speed, forming a zone with reduced pressure, where water is sucked from the outside to compensate for the low pressure. In other words, the ejector pushes water to a height from which the pump can already suck it.

The efficiency of the ejector is characterized by the coefficient of ejection, which shows the amount of sucked water per unit amount of recirculated water. In our case, the ejection coefficient for water is 0.12, that is, when the flow rate in the ejector is 1000 l / h, the ejector will suck in about 120 l / h.

The design of the ejector (option 1)

The simplest ejector can be assembled on the basis of a tee and choke - these details will serve as the Venturi tube in a very simplified version. Shaped elements for the ejector can be used from various materials (metal, plastic). In this case, the design of the ejector is assembled from a brass tee and collet fittings for metal pipes.

The diameter of the shaped elements for the design of the ejector is taken depending on the performance of the pumping station and the diameter of the suction and recirculation pipe, the diameter of the suction pipe can not be less than 25 mm. In our construction, a tee with a diameter of 20 mm will be used with a 26 mm suction pipe and a 12.5 mm recirculation pipe connected to it.

- Tee? "Mm.

- The union? "Mm and with branch of 12 mm.

- Adapter 20? 25 mm.

- Angle 90? (external / internal) for a metalplastic pipe? "? 16 mm.

- Angle 90? (external / internal) for a metalplastic pipe? "? 26 mm.

- Angle 90? (external / internal)? "??".

The difficulty in this design can make a choke, it will have to be slightly modified, namely, to turn the hexagon to a cone-shaped state.

The lower base of the formed cone should have a diameter a few millimeters smaller than the outer diameter of the thread of the nozzle, it is also necessary to shorten its thread to a maximum of four turns. Using a die, you need to drive the thread and cut a few more turns on the resulting cone.

Now you can assemble the ejector. For this, the fitting (2) is screwed in narrowly inside the tee (1) so that the fitting goes 1–2 mm beyond the upper edge of the side outlet of the tee, and so that at least four turns on the internal thread of the tee remain so that (6). If the remaining free thread of the tee will be missed, it will be necessary to grind off the threads of the union, in case of shortage of the length of the union, you can put a piece of the pipe on it. By the outlet (5) through which water will be sucked, it is necessary to attach a non-return valve so that when the system starts up, the water does not overflow from the suction and recirculation water supply system, otherwise the system will not start. You also need to seal all threaded connections with any sealant.

Such an ejector will not have a high ejection coefficient due to the imperfection of the design of the Venturi tube, so it can be used to lift water from a depth of not more than 10 m.

Option 2

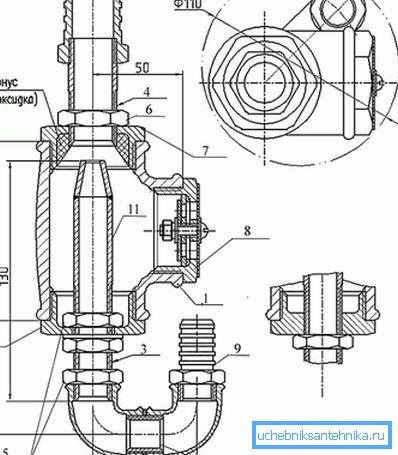

There is another option how to make an ejector, such a design is more efficient in view of a more perfect Venturi tube, it is more difficult to manufacture, but the ejection coefficient will be higher than in the previous model.

- Tee? 40 mm.

- Tap 90? 1/2 "mm.

- Sgon 1/2 "mm.

- Sgon 3/4 "mm.

- Locknut 1/2 "mm.

- Locknut 3/4 "mm.

- Stub.

- Check valve

- Union 1/2 "mm.

- Fitting 3/4 "mm.

- Nozzle 10 mm.

- Threaded sgon 1/2 "mm.

Such an ejector is made of steel shaped parts. As a nozzle (11), you can use a copper tube, make longitudinal cuts in it, compress, and solder the seams. In the plugs (7) it is necessary to make holes of a suitable diameter and cut the threads in order to screw in the slopes (3 and 4) and fix them with lock nuts. The nozzle will need to be fixed in the sweep by soldering.

Features of installation and operation

The work of the ejector will be effective only on powerful pumps, at least 1 kW with high performance, and depth of installation of the ejector no more than 20 m, installation deeper dramatically reduces the efficiency of the ejector. So that when the pump with the remote ejector does not fail, it is necessary to place the inlet pipes to the ejector strictly vertically. Be sure to have a coarse filter in front of the pump, since such pumps are very vulnerable to abrasive particles that can damage the pump. Before the pump, on the recirculation pipe, it is imperative to install a valve so that you can adjust the amount of return water, thereby adjusting the efficiency of the suction of the ejector.

A photo