Electric faucet for water: technical description

Installation of the heating and water supply system at home is not complete without installing shut-off valves. They are necessary to control the movement of fluid in the pipeline. This article will focus on automated models.

General provisions

Why do we need faucets on the contour of the pipeline? With their help, you can isolate individual sections with your own hands in order to carry out repairs or completely replace damaged elements.

Additional difficulties associated with the use of electric cranes

What is the purpose of their automation, because it provides additional inconvenience:

- Increase the cost of the product.

- The need to connect to the electrical network.

- The increase in space occupied.

- The appearance of additional nodes that may break.

Opportunities

But you can with their help:

- Increase the safety of using water circuits. Any plumbing equipment does not last forever, as regards both the instruments connected to the pipeline and the pipes themselves. And if a leak that does not appear is not eliminated in a timely manner, it can cause flooding not only of your apartment, but also of the neighbors living below. And even if you live in a private house or on the first floor, you should not forget about the basement, and the expensive flooring. (See also the article How to install a faucet on the sink: features.)

- Make autonomous watering the garden in the country, setting the frequency of switching on and off the shutter mechanism.

- Facilitate the filling of the pool, aquarium and other operated tanks, making a convenient remote control system for supplying fluid to them.

Kinds

To date, two variants of electric cranes can be used:

Electromagnetic

Principle of operation: voltage is applied to the electric coil, as a result of which the core blocking the movement of water is pulled in. The main work in maintaining the valve in the open state is performed by the flow itself.

Tip: do not use this device in gravity-free systems, as it simply will not work due to the lack of necessary pressure.

Benefits:

- The relatively low price of the device itself and its operation.

- The possibility of repairing the crane in the place of its installation without prior dismantling.

Specifications:

| Parameter | Value |

| Voltage | 12V |

| Nutrition | Permanent |

| Weight | 250 g |

| Power | 5 W |

| Operating pressure | 0.8 MPa |

| Liner section | 1/2 |

| Permissible fluid temperature | 130 degrees Celsius |

| Body material | Bronze |

| Electromagnet Material | Polyester resin |

Tip: it is recommended to install a coarse filter in front of the crane. This will significantly extend its operational life.

As we can see from the table above, such an electric tap for hot water is also great. (See also the article Connecting a washing machine to the sewer and water supply: features.)

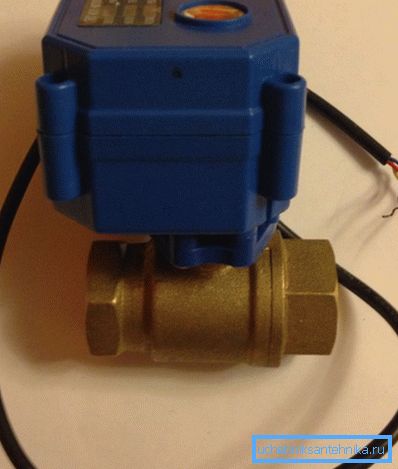

Sharovy with servo

This version of electrical valves is more practical and versatile, but at the same time more expensive and has large dimensions.

It consists of two main parts:

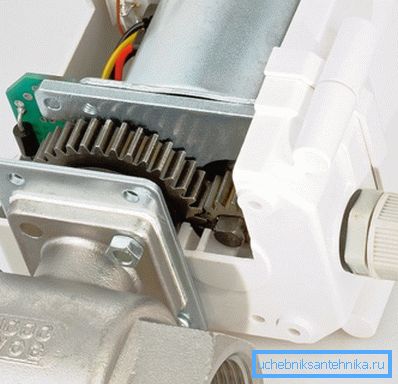

- Ball valve. The working part of such a product is a steel ball with a through hole, the diameter of which is usually equal to the cross sections of the connecting pipes. Thus, this part, turning 90 degrees in one direction or the other, opens or closes the passage for liquid. It is connected to the servo by a special rod.

- Electric drive When switching on, the motor and gear-wheel drive rotate the rod in one direction or another, respectively, closing or opening the shut-off valve.

The instruction manual of such a device is quite simple. It is noteworthy that, unlike an electromagnetic device, this sample changes its state regardless of the presence of pressure in the pipe. It is also worth noting that electric ball valves are usually equipped with manual shift knobs in case of a power outage.

Specifications:

| Parameter | Value |

| Voltage | 220 V |

| Angle of rotation | 90 degrees |

| Turn time | Half a minute |

| Servo mass | 1.5 kg |

| Power | 22 W |

Implementation of leakage protection

An electronic water faucet is most often installed to protect housing from flooding.

This is done as follows:

- We mount the automation unit.

- We cut the valves into the pipeline. Usually a single device at the entrance of the water supply

- We install and connect liquid control sensors to the automation unit. They should be placed in places most likely to leak: washing machines and dishwashers, old connecting nodes.

- We connect the electric drive of the crane to the controller.

- We test the whole system.

In the case of water in the locations of the sensors will work automatic, which will block the water supply and interrupt the process of flooding.

Conclusion

The ball valve can be electrically driven to automate its operation. This opens up additional possibilities for the use of stop valves, which include the creation of a leakproof pipeline system. It is also possible to use electromagnetic models, which have some differences described above.

The video in this article will introduce additional materials. Take care of the comfort and safety of using water supply systems.