Electric water valve with leakage sensor

An electric faucet with a leakage sensor helps prevent such trouble as flooding the housing. Therefore, such devices have recently become quite popular among residents of apartments and houses. Below we take a closer look at what a similar system is and how it is mounted.

Principle of operation

Today there are two types of sensors:

- Wired devices that connect to the controller using wires;

- Wireless - send a radio signal to the controller.

In any case, the scheme of the system is as follows:

- When the sensor is immersed in water, its poles become closed, as a result of which the device sends a signal to the controller.

- Next, the controller transmits an electrical impulse to a water valve with an electric drive that cuts off the water supply.

It takes no more than fifteen seconds to close the valve after the sensor triggers. To resume the supply of water, you need to press a special button located on the housing of the electric drive. A competently installed system guarantees protection against sudden leakage of the water supply system or the heating system.

What the system consists of

So, with the principle of the system we have read. Now let's take a closer look at the features of the elements of which it consists.

Electric crane

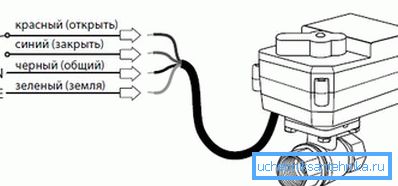

This device is a valve in the form of a ball valve with electric drive. The difference from the mechanical ball valve is only that the position of the locking element is not regulated by a lever, but by an electric motor.

Tip! It is quite difficult to install a ball valve with an electric drive with your own hands, since it is connected through a terminal box with a PVS3x0.5 power cable. Therefore, this work is better to entrust a specialist.

For sealing the connection of the locking mechanism with an electric drive, sealing rings are included in the device kit. As a rule, they are made of alloys that are resistant to wear and pollution. The locking ball element itself is usually made of stainless steel and is characterized by good durability.

The following materials can be used to manufacture the device body:

- Cast iron;

- Bronze;

- Stainless steel or other metal alloys.

It should be noted that electric drives can be designed for different voltages, most often for the considered purposes, ball valves with electric 24v DC and 12V DC are used.

As a rule, install the electric actuator on the ball valve 1 - 2 inches, 1 inch and? inch diameter. Often, devices can not only block the flow of water, but also give a sound or light signal.

Tip! Before ball valves, it is advisable to use water purification filters. In this case, their life will be increased.

Below are other characteristics that have ball valves with electric drive for the house:

| Power consumption | 7 W at closing |

| Time to full close | 5-7 seconds |

| Operating temperature range | -10 + 50 degrees Celsius |

| Maximum fluid temperature | +90 degrees Celsius |

Tip! These valves can be used not only in water supply systems, but also heating. Moreover, the three-way valve with electric drive for heating allows not only to block the flow of coolant, but also to redirect it, for example, from the radiator to the bypass.

Water leakage sensor

Mounted in places where there is the most chance of leakage:

- Near washing machines;

- Vann;

- Near the sinks;

- Shower cabins, etc.

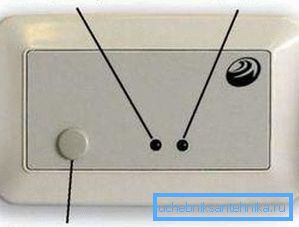

As mentioned above, when water enters the sensor, it sends a signal to the controller. These devices must be connected to a safe power source so that if you accidentally touch the plates, you will not get an electric shock.

Note! Manufacturers recommend every three months to wipe the plates of the device with a wet sponge. This operation is performed as a prophylaxis and to check the performance of the system.

On sale you can find sensors of both foreign and domestic manufacturers. The price of the latter is lower, while the quality is not inferior to foreign analogues.

Controller

This device performs several functions:

- It processes the signal from the sensors;

- Gives voltage to the electric ball valve;

- Provides power to the sensors;

- Provides sound and light alert.

The controller can be located in any accessible place where water cannot get on it. The number of elements in the system may be different, depending on the features of its installation.

Installation Features

Before installation of the system, it is necessary to draw up the layout of all its elements. Then, in accordance with the scheme you need to make sure that the length of the connecting wires is sufficient.

The installation itself is carried out in the following sequence:

- Marked areas of location, cranes, sensors and controller.

- According to the scheme laid wires.

- Crash ball valves.

- Installed sensors.

- Connect controllers.

Below we take a closer look at some of these operations.

Insert ball valve

This device is installed on the pipeline inlet after manual valves. It is strictly forbidden to use a ball valve for an electric drive instead of valves on the input.

As mentioned above, the installation of the device itself is best left to experts. At the same time you should immediately provide uninterrupted power for it.

Sensor installation

The sensor can be installed in two ways:

- Floor mounting - involves inserting the sensor into the floor covering in areas where water is likely to accumulate in the event of a leak. Contact plates in this case are brought to the surface so that they are raised to a height of a few millimeters. The wire to the device is carried out in a corrugated pipe.

- Floor mounting - the device is laid on the floor surface with contact plates down.

Controller installation

Power to the controller is supplied from the power cabinet. Zero and phase is connected to the device according to the scheme.

The installation manual for this device is as follows:

- The first step is to make a hole in the wall for the junction box.

- Then you need to pierce the grooves for the power wires from the location of the device to the power cabinet, as well as to each ball valve and sensor.

- Next, a mounting box is installed on the place prepared in the wall and the controller is fixed in it.

- After that, you need to remove the front cover of the device and connect all the wires according to the diagram.

- At the end of the work you need to replace the front cover of the controller.

If the system is correctly assembled, after it is turned on, the indicator on the controller starts to glow. In the event of a leak, the color of the indicator changes from green to red, and the buzzer sounds. At the same time the crane blocks water supply.

Here, perhaps, are all the main points of installing a flood protection system.

Conclusion

Motorized ball valves with leakage sensors are a useful invention, since they avoid a number of serious problems associated with flooding. The only thing you need to properly install the system and test its performance.

From the video in this article, you can get more information on this topic.