Entering the pipe into the well: various mounting options

Modern familiar amenities in a country cottage will make your stay comfortable. It is especially important to have a pipe entry into the house from a well in the usual absence of centralized water supply. This task is quite feasible even for non-professionals, so we will select the most suitable for us method of local delivery of such natural benefits from our source.

The optimal solution is to install the sgon, i.e., threaded pipes from 2 ends, as well as to compress the ring wall with 2 flanges on the gaskets. This is how we make the connection and this is simple, but we will reliably solve the question of how to seal the pipe.

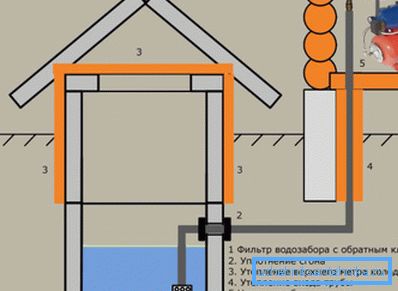

Well routing to the house

Before starting work, let us specify the probable depth of freezing in our area according to SNiP.

Pipes, their characteristics

For distributing water from the well into the house (the initial supply of it to the housing and the input of water into the building) use the HDPE pipe.

- The optimum diameter for laying underground is 32 mm with a wall thickness of more than 2 mm.

- The length of the pipe under the foundation inside the house and into the well should be with a half-meter margin.

Plumbing pipes made of aluminum with double-sided polyethylene coating are now at the peak of their popularity: they are durable, practically eternal and do not affect the taste and smell of natural water. In addition, their smooth surface prevents clogging, protects against condensation and never rust.

Competent choice of pipe diameter also contributes to our comfort:

- too narrow pipe moves with noise (flow turbulization occurs),

- calcareous deposits will soon appear inside it.

The correct diameter will be obtained when calculating the maximum flow velocity (usually 2 m / s) and the length of our pipeline:

- at 30 m, a diameter of 25 mm is needed - this is 1 inch;

- for a longer line - 32 mm - already 1.25 inches;

- on the system up to 10 m - only 20 mm.

- For such a highway from the well we dig a trench in the ground (the depth of the ditch is 1.5-2 m), we bring it directly under the foundation of the house.

Input device

- From the end of the pipe directed to the house we will retreat half a meter and fix an innovative heating matrix cable on it with foil tape.

- Its final electrical termination will be located at a 2-meter depth in the direction of the well.

- The upper end of the cable with the pipe should be 20 cm above the floor level (fair).

- Now we will put on a tubular heater on the whole pipe.

Tip! The wall thickness of the insulation is more than 9 mm, and the inner diameter is 35 mm. Such a heater-compensator will save our highway from soil deformations with the inevitable shrinkage of an already buried trench.

- The joints are sealed with reinforced tape.

- The pipe prepared in this way is laid in a trench dug, and at the point of its entry into the well we drill 2 holes in the rings with a perforator.

- Now for 30 cm we will introduce a pipe into the ring.

- In the trench we stretch the electrical cable of the pump, which is already in the HDPE pipe with a diameter of 20 mm. And we bring it inside the ring, but through a different hole.

Note! Experts advise using a waterproof PVA cable of 4x1.5 mm for borehole pumps - its price is not much higher, but reliability is much higher.

- In the same pipe we conduct an electrical PVA of 3x1.5 mm cable sockets for the pumping station, the second pump or the lighting. To do this, we make the third hole, that is, each pipe has its own hole.

Attention! Metal corrugation is not suitable for the passage of pipes through the ring, as it does not protect against water infiltration from the ground.

- Then we seal the inlet from 2 sides with a quick-hardening solution, possibly with a hydraulic seal.

- Finally, bury the trench with water.

Pipe inlet for winter water supply

Winter version is possible with any foundation - columnar or tape.

- First, we will make a warm entry of the HDPE pipe into the well.

- Here we lay a self-regulating electrical cable, insulate with foil and heat insulation with a 50-mm Energoflex, wrap it with reinforced tape.

- This end of the pipe also protrudes 20 cm above the floor. As a result, we will receive in the ground the factory final of the heating cable and a 100 percent guarantee of its tightness without a dangerous short circuit.

- Sections of the heating pipe must be sealed. We attach a heating cable to all samples of HDPE with foil, it is insulated with a porous filler, protected from damage by a reliable sheath. However, the complexity of sealing upsets.

- Warm entry into the house is done under the floor: we will dock the heating pipe with the HDPE pipe from the well with a durable compression coupling right at the depth of its usual foundation: 1.5-2m (but only in the non-freezing part of the soil).

Note! To fill the input with expanded clay, sawdust should not be so that in them, as in a sponge, do not accumulate water.

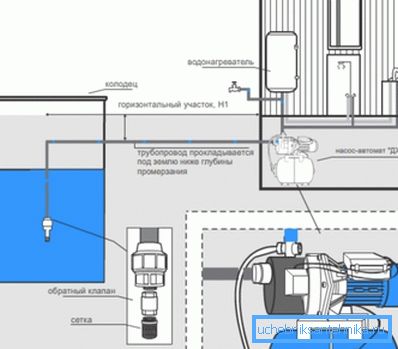

Connection of water supply station to the pipe

The installation depth is the average between the maximum level of groundwater in spring and the depth of possible freezing. So we determined the exit of pipes into the well directly from the ground.

To equip such a station in the house is simple: we connect a pipe to it with a check valve at the other end and plug it into the socket. But how to make it in the well with your own hands?

Here will help the knowledge of individual subtleties.

- On the ring inside fasten the bracket. The horizontal parts of the bracket fix the bolts on the edges of the cross member.

- Next, lower the pumping station down on the bracket.

- At the exit directly from the pump we screw the boom 1, onto it - the tee 1, and to the tee outlet - the drain valve with a swivel rod on top.

- Then we put the crane 1 on the passage section of the tee, then the compression junction - to the 32 mm pipe (to supply water to the main).

- On the suction section of the pump we wind a tap 1 (90 degrees down), on it - a compression coupling to dock with the pipe, on the coupling - the pipe down until the beginning of the second ring from the bottom.

- Now we put a check valve on its end, as well as a filter for the well - the currently popular factory-made tip with a coarse filter will do.

Entering the pipe into the sewer well

Independent introduction of a sewer pipe into the well is quite real if we carry it out in the sequence indicated by the specialists.

It will save us money and work time.

- We will begin to lay from the most remote place under the slope to the pipe that leads to the sewer well.

- Knee-shaped dips - accumulations of littering waste are unacceptable.

- The drain pipe is laid above groundwater, but not within the boundaries of the soil freezing - otherwise it must be insulated with foam plastic.

- Silicone sanitary sealant guarantees the strength of the joints, and we cut the trimmed edges of the pipes for a better and easier assembly.

- At the connection inside the house we equip the exhaust riser, and in order to improve the draft, we will arrange it above the roof.

- When connecting plumbing, we install a pipe hydraulic lock - a knee, always filled with water so that sewage gases do not get inside the house.

Conclusion

It is clear that the water supply system is the most demanded engineering system for creating healthy comfort. The instruction will help us independently, correctly and accurately build this most important local system. Such a decentralized method means connecting to an already drilled artesian well or directly bringing well water to a house.

Let's summarize the procedure.

- We wrap pipes with insulation or simple glass wool, securing it with wire and wrapping it with a waterproof film.

- We lay pre-warmed pipes in a trench. It is advisable to insulate pipes absolutely along the entire length, as well as in the places of the very entrance to the well, the house.

- Then we fall asleep a trench, periodically ramming the ground.

The entry of the system into the ring is the most critical place due to the infiltration of polluted water. It is obligatory to check the operability of the new water supply system; the absence of a leak is the expected result of our work.