Filters for wells for water - the subtleties of choice

Currently, the availability of permanent water supply in the summer cottage or in a private house is no longer a luxury, but an urgent need. Personal well, this is the best solution. But to drill it is not enough, the well should be properly equipped.

Next, we will talk about what filters on the water from the well exist and how to make them with your own hands.

Why do you need a filter

- To begin with, there is a multitude of filtration systems and a filter for a water well, only the initial part of the purification. As mentioned earlier, to reach the water at a depth is important, but not all. Without a decent filter, the system will last no more than 1 year.

- The main purpose of this type of structure is the mechanical purification of water from impurities, protection of the well walls against collapse and ensuring uninterrupted operation of deep pumps. (See also the article Which Pump is Best for the Well to Choose.)

- When choosing a filtration column, several factors should be considered:

- The first is the duty cycle, which is characterized by the ratio of the total area of the holes to the quadrature of the column itself.

- The size and configuration of the holes provide reliable retention of particles of different fractions.

- Mechanical resistance of the structure to lateral loads and axial tension.

- The stability of the columns to be in an aggressive environment.

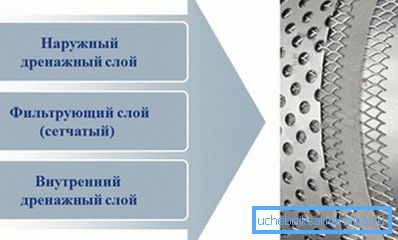

- Structurally, the system is simple, it consists of a perforated column, a filtering layer and a sump for sludge. The whole problem is the correct selection of these components.

- If we talk about artesian wells, deep, up to 200 m, then it is better to entrust the selection of columns to specialists. They will have a higher price, but makeshift filters at such a depth can ruin the whole structure.

- Fortunately, most of the wells are settled down to a maximum at the depth of the sand layer, up to 50 m. And since you have already been able to independently drill a source of water, it will be quite possible for you to equip it with a decent filter on the water from the well, and with your own hands. Next, we'll talk about it.

Types and principles of arrangement of structures

Perforated hole designs

- This system is one of the most common, but, as you know, all ingenious is just. The operational characteristics here are quite high, the column is arranged elementarily, the holes of different diameters are drilled over the entire area of the pipe.

- Columns of this type can be used absolutely for all depths, from the artesian level, to shallow wells. One of the most important advantages here is the price and ease of manufacture.

- To make a perforated filter for a well on water, a metal pipe of the appropriate diameter is taken and the holes for water entry are drilled in it..

Important: not every pipe is suitable for these purposes, the usual soft rust metal will eat in a few years, because of this, the water quality will also decrease. The best option is to use the product range for exploration or oil production, in extreme cases, just stainless steel with a thickness of 3 mm and above.

- A good solution would be to use plastic.. But here you also need to be careful, check the plastic characteristics for being in a corrosive environment and deformation. Plastic must be neutral.

Important: to ensure the quality of the column should follow certain standards. So when calculating the number and diameter of the holes, keep in mind that the total perforation area should be between 25% and more.

- The instructions for making are simple, the pipe rests on the ground, about 1m from the lower edge of the column is measured and a notch is made to arrange the perforated level. Bottom indent and will serve as a settling tank.

- After notching, we begin to drill holes, in a staggered manner.. There is a small nuance here, it is better to drill holes at an angle of 30–60 ?, in the direction from below. At the end of the process, sawdust is removed, and the cork closes from below.

- Next, to improve filtration and increase service life, you need to wrap the column with plastic mesh..

The video in this article shows one of the options for arranging the column with your own hands.

Slotted construction

- In fractured or collapsing rocks, along with perforated columns, filters are often used for water wells with a slotted principle of operation.. Their device is no more difficult than the perforated ones, but the area of the holes is incomparably higher than that of the perforated system.

- A significant disadvantage of such systems is their low bending strength.. Therefore, in their manufacture used so-called belt for rigidity. If it is simpler to say, this alternation of non-perforated pipe sections.

- Making such a system with your own hands is also not difficult. For this, a mill, gas or gasoline cutter is used, but the simplest thing is to use a hacksaw or a grinder.

- The width of the cut is determined individually, depending on the fraction of the aquifer. It can vary from 3 mm to 5 mm. The slits can cut through on the principle of the belt system, and in a checkerboard pattern. The length of the gap ranges from 25 mm to 75 mm.

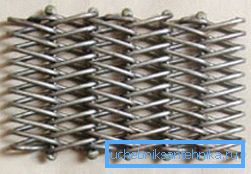

- In addition to the stiffness belts, metal mesh is used to strengthen the column. Weaving can be both square and galloon. Best of all, the brass wire mesh with braided weaving has proven itself.

- Before fastening the mesh, wrap a gasket on the pipe, which can serve as a stainless wire with a section of 3 mm.. The spiral is wound in steps of 15 - 25 mm. To fix the mesh, you can use the same wire, but with a pitch of 50 - 100 mm or solder.

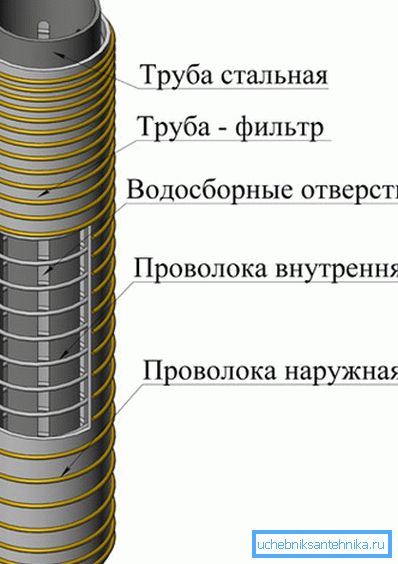

Wire Filter Columns

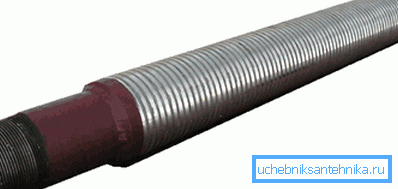

- This type of construction is much more productive than the previous two.. Such a column consists of a rigid metal frame on which a wire is wound or braided with a certain step.

- Wire cross section and configuration is determined individually for each type of rock.. Plus the wire, without fail, is soldered to the metal frame. For individual production, this option is too time consuming. Therefore, in the overwhelming majority of cases, wire filters are used for boreholes for factory-made water.

Gravel filtration principle

- Many experts consider this type of filtering to be an addition to the main column.. It is used in sandy or fine sands. It is also recommended to use it in unstable rocks and quicksands.

- The principle of arrangement is simple, it is built on the organization of a gravel layer around a seepage well..

- Gravel for these purposes is selected separately, carefully sorted, washed and calibrated.. The stones used for backfilling should be greater than the average fraction of particles of the surrounding rock, the aquifer, a maximum of 10 times.

- For the arrangement of this system, a hole of a larger diameter is drilled, with a margin for the thickness of the dumping. At the end of drilling, a pillow of gravel is poured to the bottom and a column is inserted after that. At the mouth of the column along the perimeter, gravel is poured to the height of the column. The thickness of the layer is from 50 mm.

Conclusion

As you can see, dear reader, there is nothing particularly difficult in arranging a filter for water wells with your own hands. The most important thing is to correctly determine the fraction of particles in the aquifer, and then it is no longer difficult to choose a combination of a filtration system.