Filtration well for sewage treatment

There are many ways to dispose of waste, so usually choose the one that afford the financial point of view. Effective and also the most popular option is the use of a filter well. Traditionally used in areas with a small amount of sewage, for example, in the country or in a country house.

Why is it needed

Its main task is to ensure the process of disposal of wastewater, passing it through a porous soil. The design makes it possible to remove excess moisture outside the water-saturated area (also learn how to deepen the well yourself).

Tip: install the filter well only on a site with porous soil.

These include sandy and sandy soils.

Recommended distance that must be observed:

- from a residential building - 10 m;

- from a drinking source - 30 m.

Device

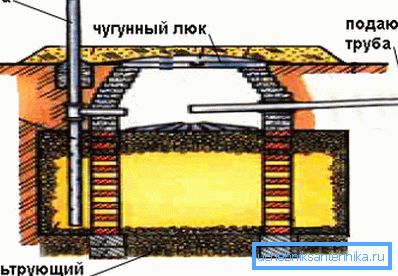

The design of the filtering well is a system that allows the sewer pipe to drain wastewater from the house by gravity to a septic tank or other settling chamber. Where they then also fall into the filter well, and then seep into the ground.

It consists of a mine up to 3 m deep, which is lined with brick or reinforced concrete rings, sometimes other materials are used.

Filtration wells occupy the area depending on the type of soil. According to calculations, 1 m2 sandy soil can filter about 50 liters per day. At the same time, sand is able to cope with 100 liters.

If you approximately know the volume of sewage water per day, you can choose the area of the future structure. The traditional size is 2 mx 2 m and a depth of no more than 2.5 m.

Tip: when making your own hands, try not to exceed these parameters.

If you need to increase the total area, it is better to make several filtering facilities. At the same time the distance between them should not be less than the sum of 2 diameters of the structures.

Do not discount another point - the level of groundwater. From the bottom of the device to the water horizon should be at least 1 m.

Features of the manufacture of the filter

Get crushed stone, brick fragments, pieces of peat, coke, slag. Make sure that the size of the filter material does not exceed 30 mm.

When wastewater enters the filter, sludge begins to form on it, which serves as a breeding ground for the reproduction of microorganisms. In the course of their livelihoods, they process organic matter into minerals, purifying wastewater.

Filtered in this way the water penetrates through the sandy soil in the lower horizons.

You can make the filter in the following way:

- determine the area of the filter well at the rate indicated above;

- prepare the material in the required amount;

- conduct a laying of fine fraction rubble, put a brick battle and slag in the next layer;

- fill the gaps between the shaft and the wall of the well with the same materials;

- final water purification will occur after they pass through the sandy layer of soil.

The shape of the structure can be round or square, and also eats a filtration conical well.

Usually for manufacturing use the following materials:

- solid concrete;

- Red brick;

- reinforced concrete;

- prefabricated rings made of reinforced concrete.

In the manufacture of buildings do not touch the bottom, veneer only the walls around the perimeter. Through it, drains will seep lower into the ground and be further cleaned.

How to make a filter well

Below is a guide that can be the basis for you.

Make adjustments to it, but do not change the essence.

- One of the most reliable structures that have proven their durability is a filtering structure made of reinforced concrete rings, although their price is not the cheapest. They must be lowered onto the filter material, which must be evenly distributed in height. Put on the bottom of the stone, which will not allow to erode the filter falling stream of wastewater.

- You also need to make all their height in compliance with the order of chess holes with a step of 200 mm. Between them, leave a distance of 50 mm. In the wells, where the walls are lined with red brick, they are made using gaps in the masonry.

- Install the pipe, which supplies wastewater to the well, at a height of 100 mm above the bottom filter with a slight slope. Its end should be directed to the center of the mine, under it set the capacity for drains with holes.

- Make a filter at the bottom of the structure. The material for it will serve as pebbles, gravel, sand and peat. At the same time in the center poured large particles at the edges - small.

- Make a well for the well from the top of the wooden panel or reinforced concrete cover. It should be provided with a hole with a diameter of 700 mm. Close it with hatches, between the covers of which put insulation - mineral wool, burlap, etc. Cover the construction with roofing material and fill it with a soil about half a meter thick.

- Fill the outside of the well with sandy loam or sand to the level of the inlet pipe. Its width can not be less than 0.5 m.

- Provide in the central part of the well, by analogy with the design of any type of septic tank, an air cavity with a cover and a ventilation pipe. Its diameter should be from 100 mm, and height - from 1 m.

Recommendations of specialists

To work did not stop, you need to prepare the tools that most often always have on a country site.

These include:

- shovel;

- wheelbarrow;

- scrap;

- ax;

- hacksaws for wood and metal;

- hammer;

- roulette wheel;

- construction knife

Your site should be your “face”, so show your design abilities to design the visible part of the filter structure. For example, disguise it as an element of the landscape.

You should also understand that it is impossible to arrange such a well on clay soils, since they do not have sufficient absorbing capacity. The next obstacle, which will not allow to install a structure on the site, is too high groundwater level.

The simplicity of the construction of the filter well and the safety of its operation are guaranteed by its principle of operation. It is often used as an alternative to underground filtration fields.

Benefits

- Due to the convenience and low cost of installation works, filtration wells are often a good alternative to difficult and more cumbersome filtering fields in the device;

- If during operation the filtration field becomes silted and ceases to function as planned, cleaning of such devices is not performed. It is necessary to carry out a complete replacement of all parts of the structure, which carries with it enormous financial expenses. The filter well is easy to clean with strong water pressure;

- Therefore, it is much easier to manufacture such a structure, when placed, which, unlike filtration fields, it is not necessary to strictly plan the construction of facilities for a suburban area;

- Filtration wells are considered the most simple and inexpensive devices for sewage treatment. Using them as a sewage treatment plant will be the best solution for a private home or garden.

Conclusion

Purification facilities on a country site are necessary. They can be various constructions, including filtration wells, with the help of which wastewater is released from negative impurities before infiltrating into the ground. His device is quite simple, so you can make it yourself from reinforced concrete or brick, in addition, for sale quite a variety of plastic options (find out here how to make a water filter for the well yourself).

In the presented video in this article you will find additional information on this topic.