Flanged crane: types, application, installation features

How are the valves mounted on the flanges? When is it justified to use them in engineering communications? Are there any subtleties in the installation of these elements of valves? Let's try to answer these questions.

Classification

First, we will understand what are the flange valves.

Device

By the way in which water overlaps, four classes of valves can be distinguished.

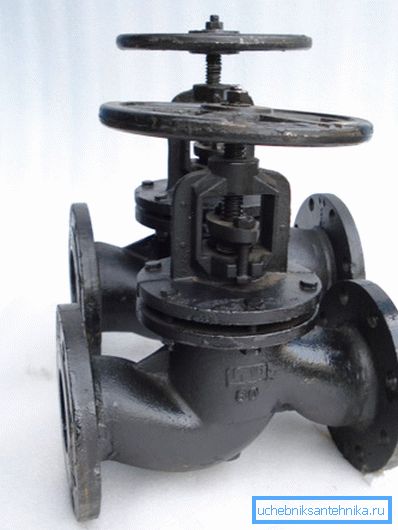

- Screw. The valve is movably fixed on the threaded rod, which is pressed against the seat in the valve body. Tightness is ensured by stuffing box gasket. It is a sealing washer, which is pulled to the body by a cap nut or a pair of bolts. This type of valve has a number of specific disadvantages:

- They can pass water only in one direction. Counter flow is not just undesirable: it is dangerous, since it can cause the valve to break off with its accompanying hydraulic hammer.

- They have high hydraulic resistance due to the complex shape and relatively small size of the hole in the saddle.

- They require periodic packing of the gland, which is produced not only with the active use of the valve, but also when idle.

- Rubber or paronitic gaskets wear during operation and also require periodic replacement.

Note: sand or dross caught under the valve often leads to complete or partial destruction of the gasket. Its resource reduces and high temperature environment.

- Cork. In them the flow is blocked by a conical stopper with a through hole. Without typical problems, it was not done here.

- With a large valve size (for example, DU65), turning the plug requires considerable effort: the resistance grows in proportion to the increase in the contacting surfaces of the plug and the housing.

- Periodic packing of the gland is required in this case.

- Shiberny. Their device is closer to the valve than to the valve: the threaded rod lowers the conical valve between the two mirrors (annular seals in bronze). Durable rubber or polymer seals are often used instead of the gland; the only notable problem is the inoperability of the valve during fouling of solid sediment mirrors.

- Ball. A brass or stainless steel ball with a through hole rotates in the valve body when the handle is turned. It is fixed by a pair of ring saddles made of Teflon or Teflon; a gasket of the same material seals the stem.

Ball valves are the most practical, convenient, durable and failsafe; at the same time, the price of a ball valve differs little from other structures of the same size.

Wednesday

Most of the flange valves for pipes offered by the market are oriented for use in water supply and heating systems.

However, you can also find solutions for other working environments.

- Gas ball flange taps have an improved surface quality of the ball, which prevents the slightest leakage. As a rule, they are marked with a yellow pen.

Curiously: the manufacturer’s instructions usually allow the use of gas valves in pipelines transporting not only gas, but also water, oil products and steam with temperatures up to 150 C.

- Ball steam valve uses heat-resistant Teflon sealing rings, allowing it to operate in an environment with temperatures up to 250 C.

Functionality

Most of the flanged cranes provide only one opportunity - to completely shut off the current of the medium through the pipeline.

However, there are more exotic options.

- Ball flange control valve allows you to throttle the pipeline, smoothly changing its cross. The key difference between the control valves and conventional ball valves is in the form of a hole in the locking ball: it is not made round, but oval or more complex.

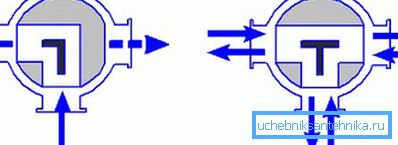

- The three-way ball valve also differs in the shape of the notch: in this case it is made angular, which allows to realize the principle of either-or. The flow of water from pipeline number 1 is directed to pipe number 2 or number 3.

Sizes and application

The sizes of all flange valves produced by the domestic industry are taken according to GOST under number 28343-89.

It is curious: in principle, the sizes of flanges, including those for valves, are regulated by a separate standard - GOST 12815-80. However, this document completely duplicates the range of sizes from GOST 28343-89.

We give these dimensions in millimeters and inches.

| Do | Size in inches |

| ten | 3/8 |

| 15 | 1/2 |

| 20 | 3/4 |

| 25 | one |

| 32 | 1 1/4 |

| 40 | 1 1/2 |

| 50 | 2 |

| 65 | 2 1/2 |

| 80 | 3 |

| 100 | four |

| 150 | 6 |

| 200 | eight |

| 250 | ten |

| 300 | 12 |

| 350 | 14 |

| 400 | sixteen |

| 450 | 18 |

| 500 | 20 |

What dimensions of the pipeline justify the use of flange valves for installation of heating systems or water supply with their own hands?

According to the author - starting with DU40. It is better to replace the flanged ball valve DN25 or DN32 with a coupling valve: the thread of this size can be cut by hand, with a pipe die, but the flange will have to be welded, which is often more problematic and requires complete drainage of the pipeline.

At the same time, with a large thread size, even an attempt to move the lock nut on the sgone requires an immense amount of effort. It is much easier to dismantle or replace a flanged ball valve DU80 than to disassemble a threaded joint of the same diameter.

Nuance: in contrast to the thread, the flange does not require installation of the booster and can be used in conditions of a shortage of the length of the straight section of the pipeline. However, disassembling small flange connections tightened with steel bolts is not for the faint hearted. As a rule, bolts are easier to cut than unscrew.

Installation

The tricks of the assembly flange a bit.

- Paronitic gaskets are commonly used for sealing. However, they can be replaced by self-carved from the old car camera. Do not forget to leave the tongue on the edge of the gasket, which will allow you to get it between the flanges.

- In order to avoid distortions, the flange is crossed crosswise, one or two turns of the key at a time.

- Bolts should be located on one side of the flange. In case its plane is horizontal, bolts are screwed on top. It is easier to bait the nuts; in addition, falling from a height of a light nut is less likely to cause injury to the person below.

Conclusion

We hope that our somewhat superficial acquaintance with a whole class of valves and fittings will help the reader in choosing solutions for his own projects. The video in this article, as usual, contains additional material. Successes!