Flexible hose for water supply: selection, installation and

In this article we will talk about what a flexible pipe for a water supply system is, when it is justified to use it and what are the limitations on operation. The topic of the article is of considerable interest, since in some cases the use of rigid connectors is hampered by the lack of space or the complex configuration of the adjacent surfaces on which installation is carried out.

The so-called flexible eyeliner allows with minimal effort to cope with the installation work at home and in the country in any cramped conditions.

Main varieties and their features

Flexible water pipes are used to connect these or other plumbing fixtures to plumbing.

Among the obvious advantages of this type of compound, we note the following:

- reasonable price of the finished result in comparison with the use of hard communications;

- reliability and durability of the connection, provided proper installation work;

- simplicity and ease of connection;

- the ability to perform installation work using a simple tool.

One of the important conditions guaranteeing high quality of connection is the right choice of flexible liner.

There are two types of hoses on the market today, including:

- Rubber modifications in the metal reinforcing sheath - the most affordable and easy to manufacture type of connectors. Due to ease of manufacture, the price of such products is the most affordable. Structurally, the connector is a flexible tube, at the ends of which the sleeves are pressed in - on the one hand with a union nut, and on the other with a union or also with a union nut.

Important: Despite the presence of a reinforcing braid, the rubber core is usually used to cover with microcracks after several years of operation, which negatively affects the degree of tightness.

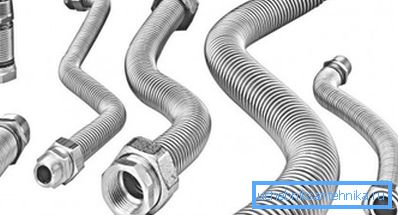

- Bellows modifications in functionality are similar to the previous product category.. But there is one significant difference, here, instead of braid, a corrugated sleeve resistant to wear is applied. Another distinctive feature is that the sleeves are not crimped, but directly welded to the sleeve. Due to such structural features, the connectors are more durable and reliable. In addition, bellows connectors are designed for a wide range of operating temperatures.

Characteristics of rubber hoses in metal braid

Modern plumbing flexible hose 1 2, as well as similar products with other sizes, is a worthy replacement for plastic metal pipes. As already mentioned, flexible eyeliner allows you to work in cramped conditions, and if necessary, move the connected mixer or sink from place to place without the need for dismantling.

The ease of self-assembly is ensured not only by the flexibility of the hose, but also by the presence of rubber gaskets inserted into the internal cavity of the union nut and the presence of sealing rings on the fittings. That is, acquiring this type of connectors, you get not only the hose itself, but also fittings for its connection.

When choosing a flexible liner with metal braid, you need to pay attention to such moments as:

- Temperature limitations. Hoses can be designed for cold or hot water. Modifications for cold water are braided with woven blue stripes, while hot water products are marked with red stripes.

- Maximum working pressure - indicated in the marking on the sticker, less often the marking is applied directly to the sheath.

- The material used for the manufacture of the tube. Depending on the content of rubber, the strength and durability of rubber may be more or less. In addition, there are products from technical rubber, which smells throughout the entire service life. At the same time, there are products made of food rubber, which does not smell and, accordingly, does not adversely affect the quality of water consumed.

- The material used in the manufacture of braid. As a rule, stainless steel or galvanized steel is used to manufacture the protective braid. It is easy to distinguish one from the other, since galvanized steel shines less and has a characteristic gray tint. In this case, it is preferable to choose products with stainless steel braid, since they do not last longer.

- Length of the product. As a rule, modifications of hoses ranging in length from 40 cm to 1.5 meters are on the market. It is important from the very beginning to choose the right length so that later you do not extend the short hose.

- The operational life of the product can last from 1 to 10 years. As a rule, the more expensive the eyeliner, the better it is.

Common operational disadvantages

What operational flaws most often are characteristic of flexible liner on the basis of a rubber hose?

- Insufficient crimping of the liner and, as a result, the possibility of leakage. According to statistics, more than half of the braided plumbing hoses are made by handicraft using non-automated equipment and sleeves of obviously low-quality metal.

- Deformation of cap nuts and fittings when performing installation work. This disadvantage is rare, but characteristic of connecting elements made of low-quality metal. For example, to reduce the cost of production, manufacturers of no name connectors make cap nuts and fittings of silumin. The use of low-quality alloys leads to the fact that the nuts are not only deformed, but also crumble.

- Reducing the tightness of the connection due to the appearance of microcracks on technical rubber of low quality. This rule is relevant both for the tube inside the sheath, and for gaskets that crack or crumble after a year of operation.

- The braiding is unwound due to corrosion of galvanized steel after a year of operation.

To prevent breakage of the water supply system, you can use a high-quality flexible hose with non-toxic rubber tubing - EPDM. Braid should be made of stainless steel (AISI-304) with a high density of weaving. Compression sleeves should be made of stainless steel and nuts and fittings made of brass.

Important: Truly high-quality brand connectors are delivered to the market with a certificate of quality and a passport.

Characteristics of the bellows

The high-quality bellows liner in the domestic market is supplied by two companies: PARIGI (TAM model range) and WITZENMANN (Hydraflex products).

This type of flexible liner is a stainless steel sleeve with brass end fittings. Due to the design features and the type of materials used, the eyeliner has a number of characteristic advantages in comparison with rubber hoses in a metal braid.

Among the advantages of the bellows are the following:

- Long service life, on average, up to 25 years, since the design does not have the most vulnerable part - the rubber tube.

- High resistance of the connector to the negative effects of chemical aggressive substances, which is more than relevant, given the composition of water in modern central water supply systems.

- The minimum probability of rupture due to excessive pressure in the network. It is more likely that the main pipe will suffer than this happens with a flexible hose, which consists of many peculiar stiffeners that provide high strength and resistance to high pressure and to hydraulic impacts.

- The minimum probability of the connector breaking at the point of fixing the sleeve and sleeve. If modifications with a usual braid are equipped with a blooming sleeve, then here the sleeve is welded.

- The hygiene of the bellows liner is due to the lack of technical rubber in the structure, which is able to release toxins into the medium being transported, and simply adversely affect the taste of water.

Installation Rules

- Before connecting the liner, we inspect the sleeve for damage to the thread, the reinforcing coating, etc. If such damage is found, the sleeve can not be used as intended.

- Half an hour after the installation is complete, we wipe the sleeve and the joints with a dry cloth and thus determine the presence of leaks.

- Try to make the nuts and fittings are made of the same material. For example, a steel nut is screwed onto a steel pipe thread. In this case, it is possible to prevent the development of corrosive processes.

- The installation instructions for the flexible hose allow installation with a bend radius 5 times the outer diameter of the cross-section of the sleeve used.

- The sleeve should be free and not stretched or twisted.

- When tightening the flare nut, do not apply excessive force (maximum permitted tightening torque is 0.4 Nm), as it is possible to break the thread, damage the nipple or push the sealing gaskets.

- Every six months you need to inspect the connection in order to promptly detect leaks or damage.

Conclusion

Now you know what a flexible leash is, what it can be made of and what are the features of its installation. More useful information can be found by watching the video in this article.