Flushing the well after silting and drilling

Whatever your water well in a country plot, after a certain time it starts to silt for various reasons, including its improper operation. It becomes noticeable bad pressure, sometimes it disappears altogether, and flushing the well with their own hands does not bring results.

But this does not mean that there is no water left in it, it just needs professional cleaning with the help of specialists.

General information

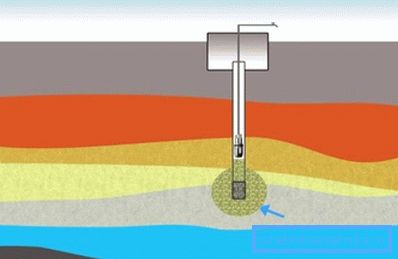

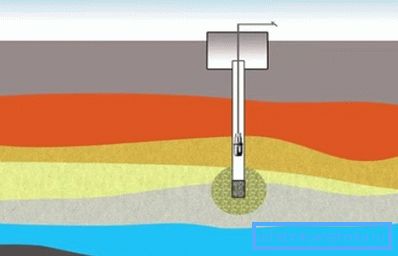

Schematically, such a well can be represented as follows:

- drilling occurs to a sandy or limestone aquifer (artesian);

- it is cased by a pipe, at the bottom of which a filter for the well is installed, and at the top for ease of use, a concrete ring or a caisson;

- after lowering the pump and turning it on, it begins to suck water from aquifers and lift it to the surface under pressure;

- in addition to the water below, silt begins to accumulate and a sand plug forms, which prevents water from entering the pipe;

- at the same time, the debit of the well begins to decrease sharply until it stops at all.

But, do not rush to look for a place under another well.

It is possible to reanimate the old one when the first signs of silting appeared:

- reduction of pressure;

- water begins to flow with an admixture of air.

From the crane begins with a loud snort to fly out the liquid, splashing everything around with particles of rust and sand. Over time, even this pressure may cease altogether.

The quicker the flushing of wells to water is organized, the better. You should start when the flow of water is still there. Otherwise, you will have to pull out the pipes and do a major overhaul, replacing the filter.

A standard household well in a country or summer cottage has an average depth of up to 25 m, and water is supplied to the surface with low-power vibrating-type pumps, for example, “Baby”. The use of more expensive centrifugal pumps such as "Aquarius" is not so widespread.

When to rinse

Most often, washing is used in the case when it is necessary to destroy the peri-pipe sedimentary rocks by pressure, which create a kind of shell at the bottom of the filter.

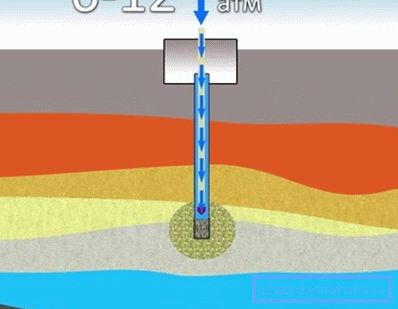

Below will be offered instructions that allow you to achieve the desired effect with minimal cost:

- Pick up a fire hose of suitable diameter.

- Attach a special narrowing tip to its end, which will increase the pressure at the bottom of the well, which should be 6-12 atm.

- Lower the end of the sleeve to the bottom.

- Use a fire engine or a motor pump for boosting the required pressure.

Tip: fit the diameter of the fire hose as close as possible to the diameter of the well.

How to wash

- Feed water into the hose under slight pressure.

- Fill the well to the top.

- Increase the pressure sharply to create a water trap in the well. At the same time, water begins to penetrate into the annular space, which makes it possible to destroy sediment.

- Increase the pressure again, and then dirt will come out of the filter and the pipe to the surface.

- Pump out water from a concrete ring or concrete when they are completely filled with water.

- Lower the sleeve even lower and continue flushing, since the place is free from sludge.

- Fill a well under low pressure, and then with an increased pressure create a water hammer at the bottom.

You will again see how various contaminants will start to fly out of the pipe. After filling the caisson or concrete ring, deflate all the water. Below are only sand and large stones.

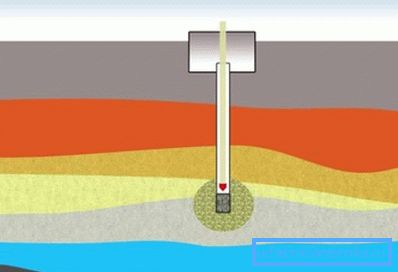

After flushing, it is necessary to immediately begin pumping water from the well. At first, the water from the well will be turbid. But it needs to be pumped out constantly, only stopping for short breaks.

If the decrease in water pressure and well debit was caused by silting, after flushing you will again have clean water at the right pressure.

Rinsing after drilling

Do not think that after you make a well, that’s all. It is necessary to spend a lot of time to wash the well from sludge and other contaminants that inevitably appear after drilling.

Tip: buy a special cable for the pump, and do not use a regular rope, as it often cannot help to pull the equipment out of the sludge.

Pump

Do not rush to install in the well "finishing" equipment. Initially, you need a special slurry pump for flushing the well for pumping, but its price is high or low-cost submersible, which will be clogged with dirt over and over again. But you keep intact the basic equipment for clean water.

Tip: Replace the vibrating pump with a centrifugal pump that can handle the load better.

Suspend it at the level of 700 mm from the bottom of the well, so it will be able to capture the silt better. Stop him periodically and clean the dirt so that he can work longer, since no one knows how long it will take to do this. The main thing is that the flushing of the water after drilling can not be interrupted for a long time, it should be almost non-stop.

Tip: when flushing it is important that the dirty water is drained as far as possible from the well. Otherwise, she will return there again, turning the process into an endless one.

Typical mistakes

- The pump is too high suspended, which cannot drain the bottom mud to the surface.

- Pump lowered too low. It quickly becomes clogged and cannot work.

- Improper discharge of water.

Conclusion

The article described two ways in which flushing of water wells was performed. It is easy to operate them, you just need to drill and equip the well correctly. In the case of silting, it is necessary to begin the process of pumping it as soon as possible, then the cost of work will be minimal. In the presented video in this article you will find additional information on this topic.