Hand pump for well main differences and types of equipment

Nowadays, the vast majority of sources are equipped with electrical equipment for pumping water, and hand pumps for wells are quite rare. Meanwhile, this type of device is perfect as a backup option in case of power outages and as the main type of water supply on the plot.

Everyone knows that weather disasters and equipment breakdowns can leave entire areas without electricity, in which case the hand pump serves as a guarantee that you will never have any interruptions.

Types and features of equipment

In fact, the options for manual devices for pumping water is not so much, most of them differ in design features and configuration of the nodes used. The principle of operation is similar for all devices, but they differ depending on the depth from which water will be taken.

Piston pumps

As you know, this type of equipment is best suited to Abyssinian type wells, but it can also be used in water intakes of a different configuration. The main advantage of such devices is simplicity and reliability..

And if you have a small set of equipment, tools, if you wish, you can make a hand water pump for a well with your own hands. You must admit that it is unlikely that you can make any other type of equipment yourself.

Consider in detail all the features of this design:

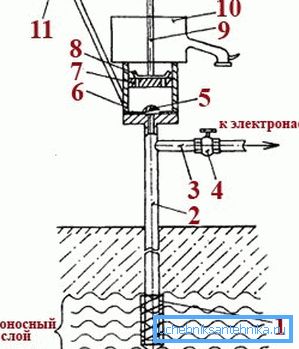

- Water is drawn from the aquifer through the water intake 1. Depending on the type of well, this can be a game with a filter (Abyssinian well), a mesh filter or a plastic filter.

- Pipe 2 leads to the surface of the earth. Its diameter and length can vary, but it should be remembered that it must meet the following requirements: due to the fact that the pump sucks water, the pipe walls must be rigid. The best fit metal or plastic.

- If the hand pump will be used in parallel with the electric one, then before the pumping column it is necessary to branch off the pipe through which water will flow into the house.

- Another important detail when using two types of equipment in parallel is a tap on a branch. When you pump the water manually, it must be closed, otherwise the water will go in two directions, and you will have to pump a lot. But the easiest way to put a check valve, and you do not have to constantly block the line.

- Next comes the body of the hand pump, in which all the main working parts are located.

- The disc valve 5 operates as follows: when the piston rises, a vacuum is created under it, whereby the diaphragm opens and the entire space is filled with water.

- Cylinder 7 is the main pumping unit, which, moving up and down, pumps water through two valves.

- Piston valve 8 is located on the top and operates according to the following principle: the piston, moving down, presses on the water, which closes the valve 5, it also opens the piston valve, and the space is filled with water. And when the mechanism moves upward, the same force of water closes the valve 8, and the liquid is squeezed into the container or immediately pours out.

- Capacity 10 may or may not be present in the design, it all depends on the characteristics of use.

- The piston moves with the help of rod 9, which is connected by a hinge with a balance bar, which also serves as a handle for work.

As you can see, the basic principles of physics underlie the operation of this mechanism. There is nothing complicated in the design, so it is so reliable and unpretentious.

It should be noted that it is possible to use piston pumps with a depth of water of no more than 10 meters, otherwise the vacuum created by the device will not be enough for lifting water. (See also the article Connecting a pumping station to a well with your own hands.)

Sucker rod pumps

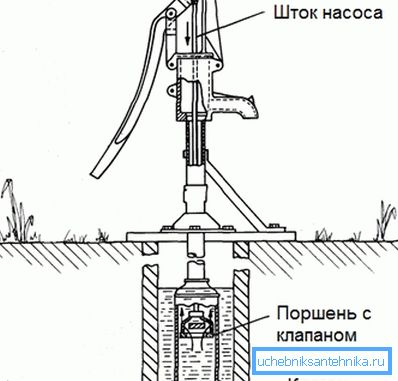

This type of equipment in many ways resembles the previous one, but there are structural differences, by virtue of which such pumps can pump out water from great depths. Their main advantage is the location of the pumping mechanism, it is at the bottom, so the depth does not matter so much.

Consider the principle of operation of this device:

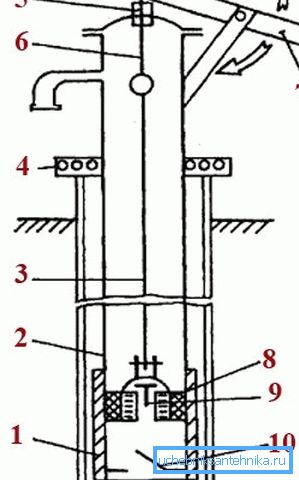

- Pump cylinder 1 is located at the very bottom of the design, the main thing in this node is strength and geometric correctness.

- The cylinder is connected to a water pipe that goes to the surface itself, where it is rigidly fixed on the casing of the well or on the concrete wall of the well with a special clamp.

- The pipe to the surface is a set of rods 3, with which the force will be transmitted to the mechanism.

- The rods are connected to the main pumping unit, the piston 8, with the help of a special system. This part should be well fitted to the cylinder, since the performance of the system directly depends on this.

- At the bottom of the cylinder is a suction valve 10, which can be of various configurations - both disk and ball. It opens when the piston moves up and closes when it moves down.

- The valve 9 is located in the middle of the piston, it should be a special groove for better performance.

- In the upper part of the rod is connected with the rod 6, which is pivotally connected with the balance weight 7, which performs the functions of the drive handle.

- In the place of the stem outlet from the body, an oil seal is placed 5, it serves to prevent dirt and precipitation from entering the structure.

Tip! As practice shows, the best seal of the piston in the cylinder can be ensured in a rather simple way: by attaching a piece of rubber or leather to its upper part, cut out according to the hole pattern.

The main features of the operation of sucker rod pumps, which must be taken into account:

- Remember that the bottom valve must always be in the water, so it is necessary to immerse the pipe in water so that when pumping the structure is not above the level of the water horizon.

- When installing and fixing the design, the piston should be set so that in the lower position it does not reach the valve by 5-6 centimeters.

The principle of operation of the device is quite simple: when the piston moves down, the lower valve closes and the pressure of water opens the upper valve, as a result of which the fluid passes into the space above the cylinder. When moving upward, the process is reversed: water closes the upper valve, and a vacuum under the piston opens the bottom valve.

The main features of self-manufacturing pump

As you know, the equipment can be purchased in the finished form, but often its price is quite high, and such costs are not justified when used at the dacha or as a backup option.

In this case, you can make the device yourself, and our instructions will help with this:

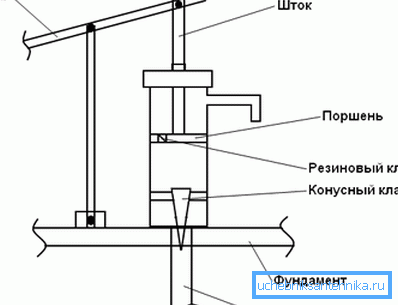

- Pump casing, ideal option - a piece of a pipe from usual or stainless steel. The length of the part should be approximately 80-100 cm. Before use, the internal surface should be checked for smoothness for best performance.

- The top cover is made either of metal or of durable plastic. A hole for the stem is made in the middle, and a sealing gland is fitted to ensure the highest reliability.

- Next is to take care of the manufacture of the piston - suitable plastic or metal. Ideal - a piece of pipe of smaller diameter, passing inwards with small gaps. Do not forget about the rubber or leather seal, the tighter the piston will move, the higher the performance will be, however, too tight fit makes it difficult to work well pump.

- Pipes on which water will flow must be sufficiently strong and dense, the use of hoses is not allowed.

- Pay special attention to the valves, they should be quite reliable so as not to let the water through when the pump is not working. This work is best done with the help of a qualified professional.

Important note! Many make the mistake of installing the pump without a base, the design is subsequently loose, which can lead to breakage of individual components. It is best to firmly fix the body, and if it is an Abyssinian well, you can pour a small tie.

Conclusion

Despite the total automation of our livelihoods, it is better to always have a backup option in case of power outages. (See also the article How to choose a pump for a well: selection criteria.) That is why hand pumps will never lose their relevance. The video in this article will help to better understand this type of equipment.