Hdpe crane: design features and scope of application

Today, more and more often, pipes made of HDPE - low-pressure polyethylene are used in the construction of domestic and industrial pipelines. This material facilitates the installation of networks, increases their reliability and extends the service life.

Another advantage of plastic systems is the simplicity and quickness of locking devices on them. As a rule, these are special PND taps and valves.

Features of ball valve

In most cases, these valves are ball type.

Scope of application

Fittings and taps for HDPE pipes are placed at the junction points of different parts of the network, in addition to this - at the flow control points.

Note! They guarantee airtight mates. In addition, they provide an opportunity to open / close pipes, as well as regulate the flow of substances passing through. Among them are cold, hot, aggressive chemical gases and liquids.

Ball valves with a diameter of 20/150 mm or more are used in the PND systems:

- drinking and technical water supply;

- sewage;

- gas supply;

- glaze;

- transportation of technical and chemical liquids.

Device configuration and materials

Ball devices differ in material production. The most commonly used plastic taps for HDPE pipes, brass and steel.

By design, such devices are known:

- corner;

- checkpoints;

- multi-pass (three or more inlets).

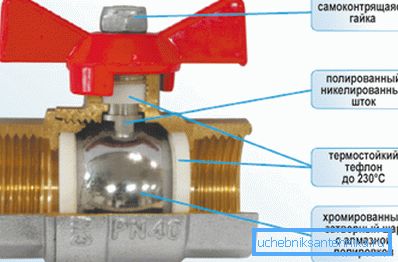

Regulating or locking element in the ball valve has the shape of a circle with two holes. It is connected with the handle of the device and moves around its axis. When positioned relative to the flow of the medium by the holes, it lets it flow, when placed by the blind side it locks it.

Types of drive mechanism

Among other things, stop valves for plastic pipes is different in the principle of the drive mechanism.

- In household networks with a small cross-section of pipes, the flows overlap the taps for pipes PND 25, 32, 50, etc., with a manual control method. Those. their handles are rotated only with their hands. This method is typical for pipelines mounted on accessible sites. On this basis, the access points to the crane should be equipped with additional protection - a fence or a locking mechanism.

- Widespread and devices with gear. Such an actuator increases the manual force, thus facilitating the change of position of the crane.

- Pipelines with a cross section of 150 millimeters and more do not overlap with their own hands. In this case, apply automatic or mechanical types of drives.

The method of their management can be:

- hydraulic;

- electric;

- pneumatic.

Note! Such devices can provide remote control or full automation of the closing / opening of the pipeline, based on certain conditions. For example - the set air temperature.

Installation Methods

To mount the crane 63 PND or other section, apply several methods.

- Butt or thermistor welding gives the highest tightness to the joint. The crane at the same time cannot be dismantled and reused.

- The flange connection allows you to use the valve several times and change the device without using special equipment. Valves on the flanges for pipes have only two provisions: “open” and “closed”. This eliminates the possibility of adjusting the flow. Such cranes are made of stainless steel or cast iron. They are used on large-diameter systems: gas, oil pipelines, etc. The devices have high strength. Their body is prefabricated of two elements or cast.

- Coupling coupling is used in gas, heating and water supply networks having a diameter of not more than 45 mm. Such valves for HDPE pipes 32 and other sections, are easy to install and easy to use.

- The fitting, or compression (crimp) ball valve is mounted using nipples and nuts. The points of the connections are sealed with gaskets. Nipple coupling allows multiple use of devices.

- Possible and the combined installation of the crane. In this case, welding of elements having the same cross section is used, for example, 32-32 and flanges.

Pros and cons of ball valves

The advantages of ball valves for plastic pipes are listed below.

- Long service life.

- Reliability of HDPE cranes is expressed in guaranteed flow shut off and their complete sealing.

- Devices can be used as a flow controller.

- The device has a minimum of parts. Due to this, its price is not too high, and the probability of failure is reduced.

- The flow can be blocked very quickly. This ensures maximum network management efficiency.

- As a rule, for installation of the crane (an exception - welded interface) the special equipment, rather usual keys is not necessary.

Disadvantages of devices.

- The limited size ruler. The larger the pipe section, the more difficult it is to find the ball valve for it.

- When the device is used to adjust the flow and may not completely overlap, it is capable of depressurization during operation. This is due to the deformation of the locking ball, which is experiencing the action of a gas or liquid in the network.

- The instruction warns that such devices can be used in gas pipelines with a pressure not exceeding 10 bar and water supply networks with a pressure not exceeding 16 bar.

Conclusion

Cranes designed for pipes made of HDPE provide an opportunity to create optimal conditions for the use of systems transporting liquids and gases. Due to the variety of models, they can be chosen for all types of pipelines.

The video in this article will help you understand the topic more clearly.