How is the drilling of wells

Most people imagine earthworks with the use of technology as an indescribable mess on the site, but nowadays hydrodrilling of wells with their own hands looks quite different. There is no need for huge cars on a wheeled or tracked drive, which trample the entire adjacent area and, moreover, sometimes can not enter the yard because of the air pipeline or the nearby power lines.

Below we will talk about the benefits and possibilities of hydro drilling, and we can also watch the thematic video in this article as additional material.

Benefits and technology

New opportunities

- Currently, several dozens of methods are used for drilling wells on a variety of soils, and their price is sometimes quite high, and the process itself is very laborious. And for the implementation of such work using high temperatures, active chemical compounds and mechanical action.

- In the method under consideration, we use the energy of water that is supplied at a sufficiently high pressure. To increase the efficiency of destruction of rocks from exposure to liquid, also use cutting and rolling cone bits, in addition to adding various abrasive particles in the form of quartz sand or steel shot to the liquid.

- Exploration or petal auger has a conical shape and is designed for the passage of dense soil, as well as centering equipment. Management is carried out using a frequency converter. The installation of the MBU and its use are regulated by the instructions from the manufacturer.

- The advantages of this method (hydro drilling) over the others are more than obvious, it is a relatively low cost, time and labor saving, as well as the ability to do all the work without attracting highly paid specialists. The most simple, common and cost-effective can be called MBU (small-sized drilling rig).

What is the MBU

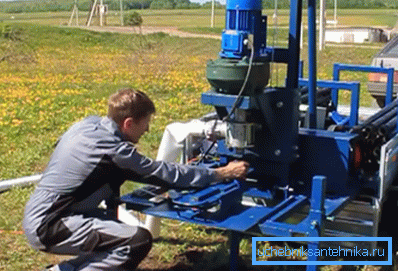

MBU is a fairly compact device that can be carried from one place to another in the hands, and for its assembly (installation at the initial place) it takes about 15-20 minutes. (See also the article How to equip a well with your own hands.)

The base of the drilling unit is a collapsible frame, on which all units, including a reverse engine with a gearbox, whose power is 2.2 kW, are supported. The engine is used to create torque, which is transmitted through the gearbox to the drill.

With the help of a winch, it is possible to raise or lower a snap in cases where there is a need to build up a working column with drill rods. Also, a water pump, a swivel on sliding fasteners and hoses, through which the working fluid is fed into the well, is mounted on the support frame, and the column is built up.

Note. In order to make a well drilling your own hands with the help of MBU, you will have to separately purchase a motor-pump, as it is not supplied as a set. Drilling with such a setup occurs by washing the soil from the well with circulating water to the surface, but such an installation is effective only on sandy, clay and loamy soils and is unsuitable for rock and some man-made formations.

Drilling stages

This method allows you to get (drilled) to the aquifer quickly enough and it may take from several hours to three days - everything will depend on the structure and density of the soil.

The drilling of a well can be divided into several stages and the very first of them will be the installation installation, which is assembled in the immediate vicinity of the well development site. To protect against vibration during the passage of dense layers of soil on the sides of the installation, additional bars must be fastened, which will serve as struts for the frame. The generator and motor pump are located in the working area. (See also the article Which Pump is Better for a Well to Choose.)

A pit is dug near the drilling site and at least one cube of water is poured in there, which can be borrowed from neighbors or in a reservoir, if there is one nearby.

Now we connect two sleeves:

- bottom - suction

- and on the top - the water supply to the swivel (see photo above).

And also we connect a hoist and an electric motor to the generator.

With the help of a hoist we lift the carriage up and onto the swivel shaft and wind the drilling tool. When the carriage is lowered to the lower position, that is, the blades of the drill are rested in the ground, it is unscrewed and the carriage is raised to the upper position. After that, a rod is wound onto the swivel shaft, and then a drill is wound onto it.

Note. If you are going to continue to produce water intake with a submersible pump, then the diameter of the well, which depends on the blades and the casing section, is extremely important. Therefore, in advance determine the diameter of the pump.

Drilling takes place with the help of blades, but the dump of soil is carried out by washing the soil out of the well with liquid, which through a small, pre-excavated groove goes back into the pit.

The filter on the suction hose does not allow the mud pump to become clogged and circulation occurs without any malfunction. The depth of the well is controlled by adding rods to the swivel shaft. (See also the article How to do well cementing.)

Conclusion

High-quality hydro-drilling of water wells depends largely on the choice of a motor-pump and in order to ensure the greatest performance effect, use a mud motor-pump with a capacity of at least 1000 liters per minute. Follow the instructions and you will succeed!