How to break a hole with your own hands: a guide

Many suburban areas that are located in suburban areas may not have a centralized water supply system from the city, and even if they have, then, as a rule, such systems are not properly maintained and interruptions in water supply are a frequent occurrence due to regular breakdowns.

Country plots far outside the city may not even have local watering from the nearest reservoir. However, if various vegetables, fruits or flower beds are grown on your summer cottage, then you should not count on the mercy of nature without having your own source of water for watering.

The most reliable source of clean water in unlimited quantities is its own well..

Having your own mine, you get such advantages as:

- independence from natural precipitation;

- independence from central or local water supply systems;

- unlimited freshwater supply around the clock;

Before you punch the well itself, you need to figure out what types of wells are and what technologies are used for them.

The main types of wells

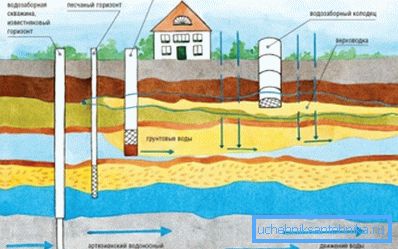

All water mines can be divided into three main types, depending on the depth.

The most commonly used types are:

- Abyssinian (tubular);

- gerbil;

- artesian (deep).

The Abyssinian spring is built in places with high groundwater storage, and its depth is usually no more than 12 meters. A pipe is inserted into the well to prevent the upper water, dirt, and dust from entering the lower aquifer.

The sand mine is installed at a depth of 15 to 30 meters. As in the Abyssinian source, a pipe is installed in the gerbil, which at the lower end has perforations for the flow of fluid from the aquifer into the internal cavity of the pipe. The service life of such a mine with intensive use is about 14-16 years.

Artesian mines are drilled to great depths from 50 to 250 meters, depending on the occurrence of aquifer limestone. This type of freshwater source is usually intended for the extraction of large volumes of water and their service life with intensive use reaches 50-60 years.

Drilling methods

Currently, several major types of drilling are actively used, depending on the soil and the depth of the aquifer.

According to drilling technology, these methods are divided into:

- screw;

- kolonkovy;

- shock cable.

In each method, fundamentally different methods of drilling are used, different equipment is used, and the final price depends on the method chosen. Before you punch a well for water, you need to find out the level of occurrence of the aquifer and the composition of the rock. Based on the data obtained, a drilling method is selected.

Drilling in the screw way

The most common and inexpensive method of drilling a well is a screw; therefore, it is according to this method that the detailed instruction is presented to you. In most cases, the site owner does not have the necessary amount of finance to order professional workers with a drilling rig, or placing the installation in the right place is not possible for various reasons.

Also, the screw method allows you to drill a well with your own hands to a depth of 5 to 30 meters without the involvement of equipment, specialists and expensive equipment.

Tools and materials

Before you start self-drilling with a screw, you need to collect certain materials and tools.

You will need:

- tripod with a height of not less than 4 meters;

- cable block with fastening in the upper base of the tripod;

- manual or electric winch, mounted on a tripod (photo);

- steel cable with a diameter of 8-10 mm, the length of which should be 10-15 meters more than the depth of the well;

- a screw with a diameter slightly smaller than the internal diameter of the pipe for the mine or more, depending on the type of soil;

- bars for lengthening the screw in an amount equal to the depth of the mine;

- working rod with a handle for rotating the screw;

Tip! If you can not use the winch, you can do without it, but in this case, you will need much more time to drill. Without a winch, you will need to bury the auger in the ground to a depth of no more than 30-40 centimeters, otherwise it will be difficult to get it together with the extracted soil.

With a winch, you can get more weight and the screw can be buried to a depth of 1 meter, which significantly speeds up the work.

Note! Before you punch a well for water, it will be determined with the type of soil, since the choice of the diameter of the auger and the shaft tube depends on it. For example, when drilling in loose sandy soil, the edges of the well are constantly crumbling.

To prevent shedding, a pipe is inserted into the drilled hole, and drilling continues inside the pipe. In this case, the screw diameter must be less than the internal diameter of the pipe. In the case of dense soil, drilling to the aquifer is done without a pipe and the screw diameter must be larger than the outer diameter of the pipe itself. The guide tube is inserted after the end of drilling to the full depth of the mine.

Drilling process on hard ground

Before you punch the well itself, set the tripod in such a way that its upper part is clearly above the place of the proposed well.

Next, fasten a block with a roller on the top of the tripod and start a metal cable.

- One end of the cable is attached to the working rod with a special rotating carabiner, the second is wound on a winch. The screw usually has 5-6 turns and is attached to the working or extension rod by means of a thread or keyway.

- Next, the screw is connected to the working rod, set vertically and begin its rotation using the handles on the working rod. After the auger has entered the ground at 40-50 centimeters, it is pulled upward with the help of a winch and freed from the excavated soil. Next, the screw is again lowered into the mine, scrolled another 40-50 centimeters and again reach, releasing the waste soil.

- After the screw has entered the ground for the length of the working rod, it is taken out, an extension rod is attached to the screw and lowered into the well. At the end of the extension rod attach the working rod with a handle and continue drilling, periodically pulling out the auger every 40-50 centimeters. When pulling out the auger, the process of disconnecting the extension rods is in the reverse order. The deeper the shaft becomes, the harder it is to rotate the auger and a lot of time is spent on connecting and disconnecting the rods when extracting the next portion of the spent soil.

- At the end of drilling and the achievement of the desired aquifer, a pipe is installed in the shaft along its entire length.

Conclusion

After installing the pipe, a dirty slurry is formed at the bottom of the mine from the waste parts of the rock mixed with water, which interferes with the normal operation of the source, therefore the final stage is flushing the mine.

Before you punch a well with water, you need to prepare in advance the deep well and rotary pumps, as well as a small tank of water.

After flushing the well, it begins to fill with water and is fully operational. To prevent rapid silting of the mine, it is recommended to use a submersible pump with a lower water intake.

In more detail, many related issues are discussed in the video in this article.