How to choose a pump for the well: advice to the buyer

What are the signs that you can choose a pump for a well? In this article we will examine several different market offers and try to weigh their advantages and disadvantages. In addition, we will affect the proper installation and connection of pumping equipment.

Selection

What begins the selection of a pump for a well? We need to determine the mode of its work. For constant water supply and for periodic irrigation, the choice will be noticeably different.

Watering

In this case, the requirements for water quality and suspended matter content are minimal. Water can be sampled almost to the bottom level along with silt accumulating there.

Pay attention: the full pumping of water and sludge will have a beneficial effect on the service life and well flow rate. Clearing sediment from the bottom will improve water filtration; in addition, the increased flow will wash nearby areas of the aquifer.

Our obvious choice is a drainage pump. Its price does not exceed 3-4 thousand rubles; at the same time, a high content of suspensions, including coarse fractions, is admissible. Drainage and faecal pumps are capable of pumping particles up to 30 millimeters in size.

Do drainage pumps have any restrictions? Yes. They are associated with a limited pressure, which directly flows from the impeller device: a rare drainage pump is able to raise the water column by more than 20 meters.

Permanent water supply

Here the picture is different. We need a sufficiently large head for a long time; at the same time, the water should be filtered already at the inlet: the ingress of sand and large fractional suspensions into the water supply system from the well is extremely undesirable.

The modern market can offer us several schemes of water pumping.

Surface

This group of devices consists of an air-cooled electric motor and a cochlea, the body of which, in fact, strongly resembles a clam shell. The centrifugal impeller creates a zone of high pressure on the periphery of the cochlea; along its axis, on the contrary, a vacuum is created, which sucks water through a pipe or a rigid hose lowered into a well.

What are the pros and cons of surface pumps?

- Great performance and significant pressure. The size of the pumping station is not limited. Increasing the diameter is the simplest way to increase motor torque.

- Ease of maintenance. The pumping station does not need to be lifted to replace the gland or tighten the hose clamp.

- The absence of stringent requirements for tightness of the case. As a rule, only the terminal box on the motor housing is sealed.

- And - alas - a small maximum distance to the water mirror. It is limited to seven to eight meters. In a deeper well, the vacuum created by the pump will not raise the water column: the maximum height of the column is tied to atmospheric pressure.

Hint: overpressure in one atmosphere corresponds to a water column of 10 meters. It is precisely at this height in theory that a surface pump can lift water, creating an absolute vacuum inside the cochlea.

Thus, the choice of a well-type surface pump will be reasonable only with a shallow depth of the well.

Submersible

Submersible pumps are more common because of the fact that the depth of the well is limited only by the pressure generated by the pump. What are they like?

Scheme of work

Diaphragm (or vibration) pumps are the cheapest solution. The solenoid causes a pair of membranes to reciprocate at a frequency of about 100 hertz. In each cycle, they consistently suck water into the working chamber and push it out. The movement of fluid in the desired direction provide check valves.

Despite the cheapness, membrane pumps are only popular among summer residents; for permanent water supply they are not suitable.

Why?

- Getting a small stone in a ball check valve with a high probability means the failure of the solenoid. Its winding will quickly overheat in the absence of a constant current of water through the pump casing.

- The membranes in the process of work are continuously deformed. After a year or two, their replacement is necessary.

- Vibration dramatically accelerates the silting of the well and aquifers in close proximity to it.

- Finally, vibratory pumps have a fairly moderate performance.

The vortex pump is the classic centrifugal impeller and the cochlea in which it is located. Due to the minimum clearance between them, good performance and significant discharge pressure are ensured. However, a small lumen has a downside: vortex pumps are designed to lift only pure water, the amount of suspended matter in which does not exceed 30g / m3.

This problem is successfully and very ingeniously solved in the so-called centrifugal pump. The gap between the impeller and the casing is a few millimeters; thus, working capacity in moderately dirty (up to 150 grams of suspended solids per cubic meter) water is ensured. The inevitable drop in pressure is compensated by the presence of several stages, each of which consists of an impeller and a diffuser.

The number of stages is limited only by the total power for all impellers of the motor and the dimensions of the body. Usually their number varies from 2 to 15. Each step increases the head by 5-10 meters.

So how to choose a submersible pump for a well?

- In a deep artesian well, you can use a vortex pump.

- For shallow wells that take water from the upper aquifer, the centrifugal scheme is the best choice.

Head pressure

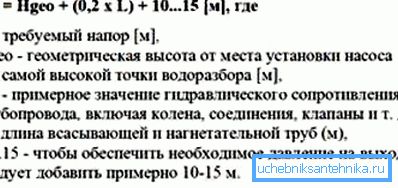

The choice of a submersible pump for a well should not be based only on its type. It is necessary to pick up the device, the pressure at the output of which will be optimal for our purposes. How to do it?

The instruction is quite simple:

- The depth of immersion of the pump is taken as the basis. It is usually suspended from a cable at least a meter from the bottom of the well.

- To this value is added 30 meters. Excessive pressure is needed for lifting water to the upper floors and for normal operation of sanitary equipment: overpressure is necessary for mixers and valves in tanks.

- The result is multiplied by 1.1. Thus, we compensate for unaccounted losses, including the hydraulic resistance of pipes and valves.

So, for a pump immersed in 14 meters, the optimum pressure is (14 + 30) x1.1 = 48.4 meters.

Please note: the head is rounded up. So, in our case, you should pay attention to the device with a pressure of 50 meters.

Performance

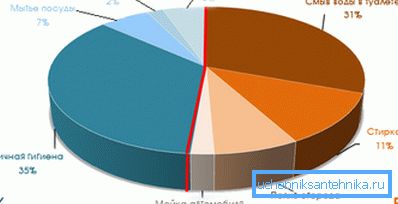

Ideally, it should be greater than the peak water demand, but less than the flow rate of the well.

How to calculate both?

- The debit of the well is easy to determine by pumping it out and noticing the time it takes for the water mirror to return to the previous level.

- For a family of 4, the rate of peak water consumption is 50 liters per minute. For more consumers, productivity is calculated proportionally.

Installation

What you should pay attention to, installing and connecting the well pump with your own hands?

- It is suspended only on a cable.. Cable and standpipe are selected to the cable clamps.

- Top Cables - Stainless Steel. Black steel in plastic sheath, if damaged, will be destroyed by corrosion within a few months.

- Between the outlet pipe of the pump and the pressure pipe or hose put a check valve. It will not allow water from the water supply system to merge into the well after the motor stops.

- The accumulator will act as a buffer, allowing the motor to stand idle and smoothing the peaks of water consumption. It can be connected at any point of the water supply system.

Conclusion

We hope that the proposed material will help you in choosing. The video in this article, as usual, will offer you more information. Successes!