How to choose a pump for the well

From the choice of the pump depends on the uninterrupted supply of water to the house with the necessary pressure and flow. There are many different models and types on the market, but before choosing a pump for a well, you should find out what differences exist between them.

The choice of the pump is made after the end of drilling and operational pumping of water. To supply water from domestic wells to water, centrifugal water pumps are used, which can be divided into surface and submersible ones.

Submersible centrifugal and vibration pump

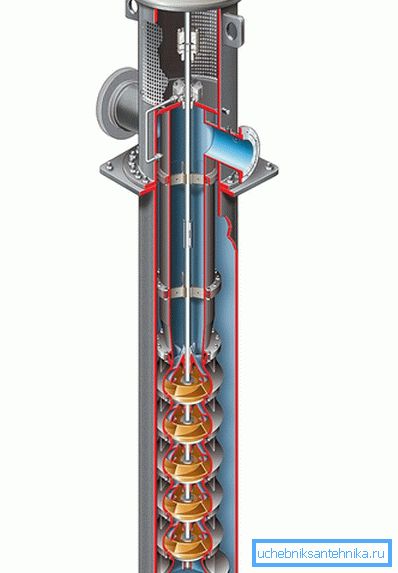

For wells, submersible centrifugal deep-well pumps driven by an electric motor are often used. The working position of such a unit is vertical, the pump itself is located above the electric motor. They are installed directly into the well to supply water from a depth of 10 m or more. Modern submersible pumps have a compact size, have a cylindrical shape and high efficiency.

The principle of operation of a centrifugal pump is based on the force interaction of the blades of the rotating impeller with flowing water around them.

Asynchronous pump motors, depending on the pump power can be single-phase and three-phase.

Submersible pumps are made from high-strength cast iron, stainless steel and have high performance properties; they can pump highly mineralized waters with high sand content up to 180 g / m3.

Vibrating submersible pump is usually used in shallow (up to 50 m) marginal wells in sandy soil.

The principle of the vibratory submersible pump is based on the operation of the membrane, which sucks and pushes water. The membrane is driven by a metal rod.

Surface centrifugal pump

Surface pumps for pumping water from a well are rarely used, since they have limitations on the suction height, which does not exceed 8 meters. They are installed on the surface. By creating a reduced pressure in the pump casing, water is sucked in, that is, it rises to the pump axis. If the suction height is greater than 8 m, the pump simply will not be able to lift water, or cavitation may occur, which dramatically reduces the efficiency of the pump and leads to the destruction of the impeller blades and other parts.

It is possible to install a surface centrifugal pump only when the dynamic water level is not lower than 5 m from the surface or the well is equipped with self-discharging.

But there are cases when the diameter of the production column is very small and does not allow to install a submersible pump, these are wells, as a rule, drilled by hand, and often have a small depth. In this case, you need to equip the pit where the pump will be installed. The bottom of the pit should be 2–3 m higher than the water level in the well.

Baseline data that determines the type of unit

Baseline data determining the type of equipment and its parameters are:

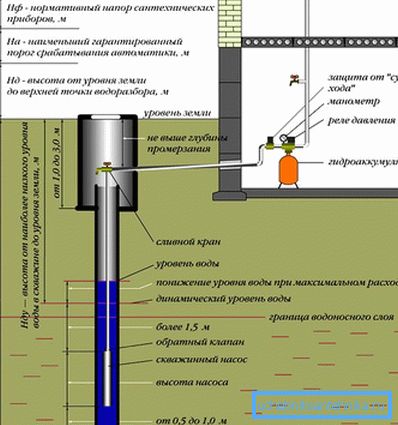

- Dynamic and static water level in the well. These parameters determine the depth to which the pump or suction pipe will be lowered, and accordingly the water pressure. The static level is established immediately after the opening of the aquifer, and the dynamic level is the level that is established in the well at the maximum pumping of water. The submersible pump should be installed at least 2 m below the dynamic level, it is better, of course, to take it with a margin, as it may fall over time due to clogging of the well or filter.

- Inner diameter of the production string. From the inner diameter of the well depends on the pump O. The diameter of the production string is indicated in the passport of the well, which is provided by the drilling organization. The diameter of the pump is chosen so that it is 1–2 cm smaller than the diameter of the production column. With a larger diameter, centralizers must be installed, otherwise the pump may vibrate against the walls of the well when the pump is running, and with a smaller diameter, you simply cannot lower the pump.

- Specific and total well rate. When calculating the performance of the pump operate on the flow rate of the well. The pump capacity must not exceed the design flow rate of the well (it is indicated in its passport). Otherwise, a situation may arise when the pump, having pumped out the water, will work dry, and in the absence of protection against dry running, it will fail.

Performance calculation

The productivity of the pump is selected by the maximum hourly flow. According to SNiP, the rate of water consumption per person is 200 l / day, that is, for a family of 3-4 people, a pump with a capacity of 30–50 l / min will suffice, depending on whether there is a pool, whether plantings. In order to smooth out peak loads and, accordingly, not to install high-flow pumps, you can install a hydroaccumulator.

Calculation of the required pressure

For proper selection of the pump with the projected water supply, it is necessary to calculate the desired pressure N. The required pump pressure is determined by the formula:

H = Hg+Hd+Hfree where -

· Ng - geometric height of water rise, m;

· Nd - head loss along the length, m;

· Nfree - free flow to the spout, taken at least 5 m.

Geometric height is the difference between the highest point of the water supply and the depth or axis of the pump. Head losses along the length are calculated using Shevelev tables, and depend on the water consumption and the diameter of the pipeline, as well as its length and what material it is made of.

With an underestimated value of O of the pipeline, the pressure loss along the length can be 80% of all losses, therefore, a correctly selected O of the pipeline plays a significant role.

Knowing the required pressure and water flow, the final decision on the choice of the pump is made on the basis of the pressure-flow characteristics. This is the curve, the passport characteristic of the pump, which displays the dependence of the head H on the flow rate Q.

There is a dependency, which causes the pressure to decrease with increasing flow, so the selection of the pump should be carried out in the zone of such conditions where the efficiency is maximum.

What is the best pump to choose depends largely on how it will be operated, and whether it will be used automation to control the pump and even the frequency of the pump. Therefore, in order to extend the service life of the equipment, it is necessary to carefully select the pump, based on the operating conditions and characteristics of the well.

Maybe you want to know the answers to such questions:

- How to get the pump out of the well?

- How to make plumbing in the country?

- What is the well pump Aquarius?

Video

You can get more information about choosing a pump for a well by viewing the video: