How to choose a submersible pump for a well: factors, types,

Lack of central water supply is the main problem of country houses. To provide the house with water, they dig a well or drill a well. But in order to supply water to consumers it is necessary to install a pump.

After all, if you can still draw water from a well with a bucket, then such a solution is completely inappropriate for a well. Therefore, in this case, pumps intended for operation in such conditions are selected.

Types of submersible pumps

To organize a constant supply of water to a country house, it is necessary to pay attention to the choice of a pump. In this case, it is necessary to take into account not only the cost of the equipment, but also the technical characteristics, the manufacturer and quality.

Before you make a choice, you should understand the proposed models.

Industrial submersible pumps for wells are divided into:

- vibrating,

- centrifugal.

Let's talk about it in more detail.

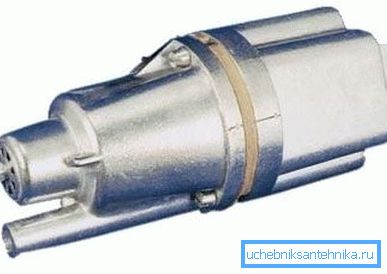

- Vibrating pumps.

The vibration mechanism creates a pressure difference with the help of a membrane that vibrates with a high frequency, and this sets in motion water. Due to low productivity, these devices are recommended for shallow wells.

They are ideal for water supply in the country.

The advantages of this unit include:

- low price;

- ease of use;

- economical power consumption;

- no rotating parts;

- low wear.

Minus - a small capacity, due to which the pump can be used only in small areas. Also negative effects include the effects of vibrations that have a damaging effect on the walls. Therefore, it is necessary to wear rubber rings on such water deep well pumps.

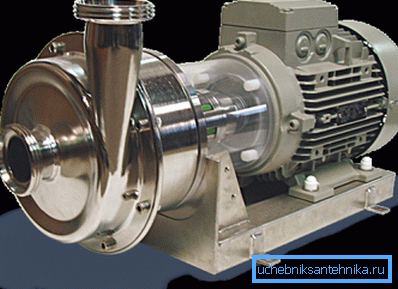

- Centrifugal pumps.

These devices for wells are able to maintain their performance over a long period. The rise of water is due to the rotation of the wheels. When it enters the outlet, pressure arises, which then pushes the liquid.

Pluses of this pump:

- good head;

- high performance;

- the presence of a large selection of models differing in their characteristics.

The basis of the centrifugal pump is a wheel with blades of a special shape. The wheel is driven by an electric motor and gives centripetal acceleration to the water washing it. The resulting centrifugal force and generates the movement of water in the right direction.

For the manufacture of wheels using cast iron, plastic or stainless steel. The use of the latter material for the production of all elements contributes to the extension of the equipment’s service life and increase the resistance to abrasive particles.

Selection factors

Well parameters

Before choosing deep well pumps for wells, it is necessary to deal with certain parameters of the water supply system. All required parameters of the unit can be found in the passport of the device.

You will only need to compare them with the parameters of the well.

- Diameter. You can find it yourself by measuring the well, or you can learn from the organization that carried out the drilling work. Measurement is carried out in inches. One inch equals 2.54 cm. Standard is a four-inch well. It is precisely on such parameters that many water submersible pumps for wells are designed.

Tip! If you decide to drill a well yourself, then make it a four-inch. This will facilitate the process of finding equipment.

- Well flow rate. This parameter shows how much water a well produces over a certain period of time. This indicator can be roughly determined by borrowing a unit from its neighbors. Lowering it into the well, note the time during which all the water will be pumped out. After this, it is necessary to observe how much the well is refilled. The flow rate will be equal to the ratio of the volume of the well to the time of filling.

Tip! In order to quickly find the volume in cubic meters of a standard four-inch well, it is necessary to divide its depth in meters by 2.

- Well Flush. It is typical for loose, sandy soils. Making the choice of a submersible pump for a well in such a soil, it is better to abandon the vibroaggregate.

Pump Parameters

Having decided on the main indicators of the well, you should consider the technical characteristics of deep pumps for wells.

- Performance. It shows how much water the unit can pump over a certain period of time. This parameter is only indirectly related to power, as it depends on throughput.

- Power. Industrial models reach 100 kW, while domestic deep well pumps come in from 250 to 5000 watts. In determining the required power take into account that the electrical system is able to withstand a voltage of 3000 watts. Therefore, when installing a more powerful device, the wiring may burn out.

- Head pressure is one of the important indicators.. So called pressure developed by the pump, expressed in meters. A pump head of 30 meters means that the pump is capable of raising water to a height of 30 meters. It should be noted that the height of water rise is considered not from the level of water intake, but from the level of the surface of the water in the well or “water mirror”. If the capacity of the unit is correctly chosen relative to the flow rate, the “water mirror” will not drop significantly during the pumping process. Of course, the final level of water rise is not the level of the ground at the well drilling site, but the level of the consumer device to which water is pumped. If the consumer is, for example, on the second floor of a house, or on a hill, this must be taken into account.

Note! You should also be aware that moving the water horizontally is considered when calculating the pressure as 10 to 1. That is, moving the water horizontally by 10 meters “steals” 1 m of the pump head.

- Body material. As can be seen in the photo, the body is made of metal, often stainless steel is used for this. Plastic can be used as an additional skin. The choice of material is influenced by the conditions in which the unit will operate. The water contains a lot of salts, because you need to choose equipment designed specifically for such water.

- Thermal protection. This is a prerequisite for normal operation. When overheating, sensors are activated that stop the pumping of water, thus avoiding emergency situations.

- Weight. This parameter affects the way the pump is installed. Models whose weight exceeds 30 kg require the use of additional structures.

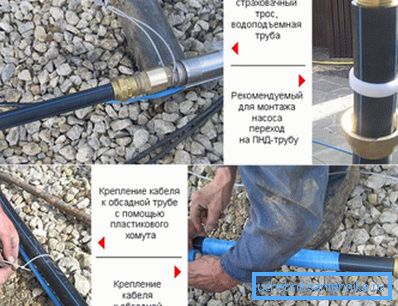

Installation of the pump in the well

To ensure proper operation of the system, you must follow the rules when installing it yourself. This procedure is not laborious, the main thing is to understand some nuances.

The following instructions will help avoid problems during installation.

- When choosing hoses, it is recommended to give preference to plastic models with a diameter of up to 2 cm.

- The pump is suspended on a metal cable or wire. However, such fastenings are considered dangerous, since due to vibrations the aluminum case at the joints can be deformed. Therefore, it is better to resort to the help of a nylon cord.

- To dampen vibrations when installing the pump at shallow depths, put a spring suspension. For this you can use a rubber band. One end of it is tied to the pump, and for the second it is suspended from the crossbar.

- It is necessary to immerse the pump to the depth specified in the passport, while ensuring that the bottom remains at least 30 cm and the pump does not touch the well. If the borehole is too narrow, put a rubber ring on the pump.

Conclusion

When choosing a submersible pump, it is necessary to pay attention not only to the technical characteristics, but also to the well parameters. The calculation will allow you to choose the pump correctly and prolong its service life.

Find out the answers to some questions will help you video in this article.