How to choose a well pump

When constructing a well for drinking water at a country site, the choice of a pump is a priority, as it can be represented as the heart of the entire plumbing system. Properly selected model, taking into account all factors, will allow uninterrupted supply of water to the specified points of water intake. The article describes in detail the rules for choosing pumping equipment, tells you what to pay attention to, and gives advice on how to disassemble a well pump when it becomes clogged with sand or clay.

Any model has its own technical features, which should certainly be taken into account if you want to get high-quality water and not repair it often enough. In addition, the choice is influenced by a lot of additional factors, since for a simple three-meter well one type of pump is suitable, for a 15-meter one it is completely different.

Criteria for selection of equipment

Well depth and water level

When you do not have clear data on these values, the well should be measured. Tie a load to a dry jute or cotton rope for this and lower it into a tubular well.

The distance to the water mirror and the total depth of the well by the wet marks are determined. These numbers are key when choosing. Usually they are listed in the passport of the pump.

Tip: keep in mind that different models can only work for a long time in a given range.

Well flow rate

This parameter indicates the amount of water that the well is able to release to the surface in a certain time.

It is not possible to measure it precisely for various reasons, but this is not necessary, it is enough to know about it.

- Lower the pump into the well.

- Turn it on and record the time it takes to empty it.

- Monitor the period when the magnitude of the water column is restored.

- Divide the second parameter into the first one, which will give an approximate flow rate.

Diameter of the well

One of the main parameters. When the well is drilled by a hired brigade, they indicate it in its passport, but you can define it yourself. The most common pump size for wells is O 3 and 4 (1 = 2.54 cm). For the latter option, models are enough, but the well pumps with a diameter of 3 inches will have to search.

There is a high probability that it will be difficult to purchase them in your city, then it is better to order it from the catalog. When there is a choice, drill a well O 4.

Water consumption

Before you choose pumping equipment of a certain brand, decide for yourself how much water you need per hour, per day and per month. Then you will immediately find out if you need a powerful motor or just take a less powerful one.

Modern pumps can deliver water to the surface in a volume from 20 to 200 l / min. Usually for a family of 4 people it is enough to purchase equipment with a capacity of 40-60 l / min.

Sometimes, however, it makes sense to buy a much more powerful pump, but its cost will be significantly higher. For example, if in addition to household water consumption, you will use it for irrigation, then immediately pay attention to models that are 2-3 times stronger than average ones.

Pump head

The value is calculated quite simply.

- Add to the depth of the well in meters the number 30. You get the height of the water column (3 bar / m), the control is carried out through the pressure switch for the well pump.

- Add to the resulting figure 10%. Example: well depth is 25 m, 25 + 30 = 55 m, 55 + 10% = 61 m.

Tip: choose from different types of pumps the one with a head equal to 90 m.

Cost of

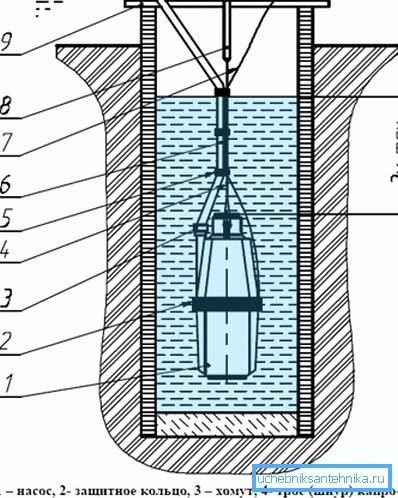

The price consists of several quantities. Before operating, each submersible pump is hung on a stainless cable and connected through a control unit of a well pump, as well as through a ROM.

Low-cost models are not always worse than elite options, although any marriage in a node can cause a breakdown of the entire system. You should pay special attention to connections located under water.

Usually, only expensive equipment has high-quality soldering. In any case, it is not worth saving on the pump, each unscheduled repair can cost a lot of money. This will negate the economic effect of the purchase, and the site will remain without water for a while.

Silting the well

Many wells are not always perfectly made, and most of them are already quite old. Pumps in such conditions can constantly be clogged or zapazkovyvatsya.

Periodic lifting, disassembling and cleaning of equipment will not be the best option. Therefore, it should be at the first stage to choose a model that is suitable for the parameters for this particular well. Let it be necessary to give more money, but after installation you will forget about its existence for a long time.

Types of well pumps

Surface

The name suggests that the equipment does not come into direct contact with the liquid. Very often the hull is installed on land, although there are models equipped with floats, which allows you to place the pump directly on the water mirror, but such options are not suitable for wells.

The surface pump is an alternative to the submersible one, with its positive and negative sides. The main criterion in the selection will play the depth with which you have to deliver water to the surface.

Such models have limitations for pumping water - no more than 7-8 m. Use for large depths is possible, but it is not economically feasible. This type of well pump can be controlled remotely.

The most reasonable option is to use this type of equipment for pumping water from shallow depths. When it is small and the water is used for drinking, experts strongly recommend using just such a model of the mechanism, since otherwise the water will be heavily contaminated with silt and sand.

Submersible

Such models can be vibration and centrifugal. However, regardless of the type, the immersion mechanism must be partially or fully located in the pumped liquid.

To say that submersible pumps are better or worse than surface pumps, but the greater the depth, the more expedient it is to use such equipment.

The instruction determines their maximum installation depth - no more than 10 m, therefore they do not apply in deep wells.

- Vibrating. The main structural element - the membrane. It is located between the fluid and the vibrator, which causes it to periodically deform. Due to the pressure difference, water begins to be pumped. These types of pumps are Aquarius 3, Streamlet, Kid, etc.

When choosing, give preference to equipment with a thermal switch, as well as to such that the suction nozzle is located on the bottom side. If the well is drilled in clayey soil, install the pump as close to the bottom as possible so that it can immediately pump out turbid water and prevent the source from clogging up. This technique is inexpensive, but it is often difficult to use.

Tip: when the vibrating pump is stuck in the sludge, pull it out when it is on.

- Centrifugal. The working mechanism of this equipment consists of one or several impellers, which are mounted on the central shaft. During operation, the fluid enters the space between the blades, and they, rotating, create centrifugal force.

Due to this, a pressure difference is created, which allows pumping water. At the moment, these types of pumps are the most popular.

If we take into account the price / quality ratio, these mechanisms are recommended from the best side. In addition, such equipment is considered universal.

Well pump

When the depth of the well exceeds 20 m, the choice of pump must be approached very carefully. In this case, it should be selected exclusively from borehole models, since the submersible and surface models are not intended to supply water from such depth. Installation and disassembly of such equipment is quite complicated, so it will be extremely difficult to do it yourself.

For example, to simply raise the pump to the surface you will have to pay for its work its full cost or even more. Therefore, in the selection of technology should stop only on the elite European manufacturers. Then, as practice shows, equipment is able to work smoothly for several decades, without stopping for maintenance or repair.

Pipe selection

Sometimes the pipe for the well pump becomes the weakest point of the system, so high-quality pipelines are also needed for good equipment. Today, polypropylene materials that meet all requirements are most often used for drinking wells.

It is very important that the weight of the pipe is substantially less than the metal counterpart, so transportation and installation of it will be much easier. Experts also insist that plastic pipe joints are more reliable than metal ones.

There is only one limitation - the pressure, which must necessarily be within the nominal specified by the manufacturer. The problem can also occur during installation in the winter, when at low temperatures the material becomes brittle.

Additional rules

Choosing pumping equipment, do not hesitate to ask the experts for advice and follow their recommendations.

Then you can significantly increase the service life of the units, while the probability of breakdowns and other problems will be significantly reduced:

- when the choice is between Italian and German manufacturers, it should be noted that pumps from Germany are considered by many to be of better quality;

- for hanging the pump, get a better thin cable for a stainless steel well pump than a thick one, but one that will rust;

- Use polypropylene pipes in clay soils, not metal or any other.

- for deep wells, use only high-quality expensive pumping equipment.

Well pump protection

Before choosing, and especially buying equipment, determine how much electricity he needs to work. This parameter is especially important when buying imported pumps, since their technical characteristics meet the standards of the exporting country.

For example, German water pumps can operate when the rated voltage in the network is changed by 6-10%. Therefore, so that you do not do and what fuses did not put, they will not work at voltages below 200V.

Keep in mind that any permissible jumps and drawdowns of electrical voltage will have a bad effect on the operation of the electric motor of the borehole pump. Therefore, it is imperative to provide protection against such voltage fluctuations, and for pumps operating on three-phase current - against operation in the case of non-phase modes.

Tip: do not put powerful single-phase pumps, since the starting current of the 2.2 kW electric motor can exceed the normal one by more than 4 times.

Use a stabilizer with a fivefold power reserve to stabilize the voltage in the operating range during such surges. It is often cheaper to make a supply to the suburban area of the line at 380 V, than to organize the protection of a powerful single-phase pump.

Statistics say that approximately 85% of pump failures for wells are their electrical part. The main reason is a short circuit of the stator windings, which occurs due to overheating or operation with abruptly changing or reduced voltage. The problem can be corrected with proper current protection, for example, using a conventional starter with current protection.

Consider that some installers do not adjust the borehole pump to the desired current. As a result, you will have to pay for equipment lifting, its adjustment, secondary descent and commissioning. Perhaps the cost of the work will exceed the price of the new equipment and its protection system.

Conclusion

Delivering water from a well to the surface can often be a complicated process. Therefore, if you doubt your abilities and cannot correctly select a well pump, seek the help of specialists to save time and money. In the presented video in this article you will find additional information on this topic.