How to equip a well: materials, methods, devices

Many private sector residents and dacha owners dig wells by themselves. This significantly reduces the cost of construction, but the process remains very laborious and lengthy. We want to tell what equipment for wells can simplify the development of rock and the construction of structures of buildings.

Earthmoving equipment

Traditional instruments

The history of the construction of wells dates back centuries, therefore traditional tools are quite simple and straightforward:

- Short-handd spade (often called an engineer or shantsevoy) and a sharp blade. Used for cutting layers of soil and the passage of rock in depth, refers to the main tools;

- Shovel with shortened cutting for loading excavated soil into buckets. It is also the main working tool for digging mines;

- Scrap. Also a mandatory attribute of earthworks, without which it is often impossible to do. As an option - scrap with a welded ax, which is very convenient for cutting and crumbling of stone, dense clay and other difficult-to-passable rocks;

- Kirk. Like scrap, it is used to overcome difficult-to-reach areas, to extract stones and boulders, etc .;

- Bucket Set. One 10-liter and one 30-liter bucket are usually enough. When using a winch or gate, it is convenient to work with a bucket with handles welded to the back side of the bottom, since for them it is easier to turn over the container without removing it from the cable;

- Tripod. It is necessary for fastening of the lifting mechanism: winches, hoists, gates, etc. It can be made independently of logs or steel pipes, and can be purchased in finished form;

- Lifting gear. It is used to lift heavy objects from the bottom of the mine, such as buckets of soil, buckets of water, stones, and others. But the main application in modern conditions is the installation of concrete rings for the casing of the mine;

- Set of ropes and cables. The necessary equipment, without which it will not work. All cables and ropes should be tested for strength, but should not have break points and ligaments;

- Chalki for mounting rings. They represent three or four bundled pieces of cable or chain with hooks at the ends, which are put on the hook of the main cable to fix the ring in a horizontal position.

Note! With the help of this simple set, you can develop a well shaft along with its casing, however, if complications arise with the composition of the rock or its structure, work can be complicated until the process of excavation is stopped.

It is also quite difficult to cope with scooping up water in the absence of an electric pump for a well, especially when building wells of a perfect design or wells with a pit. But with all the flaws, the price of all the tools listed is very low compared to electrical or mechanical devices.

Modern devices

With the digging of mines you can cope with traditional methods and tools, but do not forget which century we live in: the use of modern devices and mechanisms can not only simplify and speed up the process, but also improve the quality of the result.

First of all, it should be said about the use of power tools for earthworks. If stony ground, deposits of construction debris, boulders or just hard rocks are encountered along the path of the sinker, the use of a bump stop can significantly reduce the time and labor costs for overcoming such obstacles.

Since the dimensions of the well shaft make it difficult to use a standard pneumatic breaker (this can be seen in the arsenal of pavers and road repairmen), in our case it will be more convenient to work with an electric drill of a suitable size.

Also, small perforators can be useful for work in the mine, especially for extracting medium and small boulders from the walls. These are practically in every home set of tools, so we will not describe them in detail.

The next device I would like to dwell on is an electric pump. When excavating a mine, there comes a moment when the soil begins to saturate with water, but the digging process is not finished. Water begins to seriously hinder the work.

For pumping water from the bottom of the bottom most convenient to use electric pump. In order not to waste much, it is enough to purchase a surface unit of the vortex structure, since it is the cheapest and creates a sufficiently high pressure. Centrifugal pumps are also effective, but they are somewhat more expensive, but at the same time more productive and reliable.

At the end of the digging process, it is convenient to pump the well with such a pump, and it can also be used to clean the shaft in the future.

Seriously simplify the work of various lifting mechanisms. Most often, you can find electric winches of various modifications: removable, stationary or made on the basis of a tripod or other design. The most convenient models are made in the form of a design with a frame and a manipulator, which allows you to move loads not only in the vertical, but also in the horizontal direction.

There are also various devices for excavation from the bottom of the mine: buckets, grabs, zhelonki, bottom dredgers and other similar devices. Most often, in the factory version, they are too heavy and cumbersome for manual labor or a self-made tripod, but there are craftsmen who have managed to adapt a large one or assemble a smaller version of the grapple.

Note! What is characteristic is that with the help of bottom grabers it is possible to dig out the soil from under the water, which is especially convenient in the case of digging wells.

Equipment for the arrangement of the well

Traditionally, water well equipment includes the following elements:

- Casing construction;

- The cap with the appropriate finish;

- Canopy over the top;

- The lifting and trigger mechanism for buckets;

- Cover for the mouth of the well, better with a lock;

- Benches and table for ease of use of the source;

- Decorative elements and cladding.

The casing of the well is made by various means, but reinforced concrete rings and polymer tanks or pipes have become the most popular in our time. The use of rings allows the mine to be cased during the excavation process, which makes working at depth much safer, since there is no danger of collapse of the walls of the mine.

It is better to use rings with folds on the ends, which allow you to create a stronger, more even and airtight column. In addition, the folds do not allow the rings to shift in the horizontal direction, which is one of the most frequent and destructive breakdowns of the mine structure.

In this case, the top ring serves as a cap, which has a not very attractive appearance and therefore needs finishing. Different materials are used for these purposes: wooden bars, logs, boards, clapboard, facing brick, natural and artificial stone, polymer siding, etc.

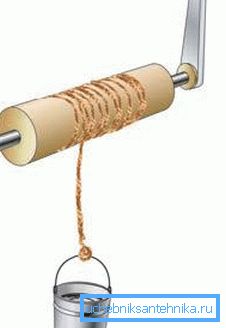

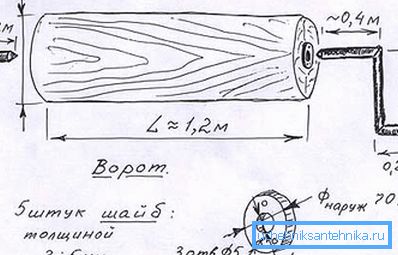

It is equally important to build lifting equipment for the well. Usually it is made from improvised means with your own hands, it can be a gate with a rope or a “crane”. The gate can be made from the usual length of a log, one axial pin of steel and a handle for rotating the mechanism. Here is the instruction for its manufacture:

For this, a length of one and a half meters is cut from a log with a thickness of 200–250 mm, which is carefully cylindrical with a plane.

Then from two sides in the center of the end face, drill holes with a diameter of 18 mm to a depth of about 30 cm.

A piece of steel bar of circular cross section with a diameter of 20 mm is inserted into one hole so that it protrudes by 10–15 cm. On the other hand, a handle is inserted which is a continuation of the axis of rotation.

Next, the device is fixed above the mouth and wound on it a cable with a hook for lifting and lowering the buckets.

In addition to the gate, the mouth must be equipped with a shed to protect it from precipitation and falling into the mine of various debris. For these purposes, a gable or hipped roof is constructed on poles on poles. Here you can show imagination and creativity, as the shape of the canopy can be very different.

Note! Try to maintain the wellhead design in the same style with the main buildings on the site, this will give your yard the integrity and completeness of the forms.

Conclusion

For the construction and design of wells using a variety of equipment, both traditional and modern. From the selection and proper use of this equipment depends on the process of excavation and construction of structures of the mine, and ease of operation of the source. The video in this article will complement and illustrate what has been said.