How to fix the tap on the hose

Of course, a rigid welded or detachable connection with polymer or metal pipes is reliable and durable, but quite often there are situations when the connection can be made only with flexible hoses. On how to connect the hose to the crane with their own hands, as well as the varieties of the hoses themselves and related fittings to them, we will discuss further.

Types of hoses and valves

It is no secret that both the hoses themselves and the taps differ quite greatly depending on the application. Conventionally, there are 3 main directions. First of all, it is the equipment intended for watering at the dacha or in the private house.

The second number is high-pressure plumbing equipment, such as a hose for a tap in the kitchen. And the last, but not less important and serious direction, the specialists allocate hoses for gas, gas valves, watering cans and other gas connecting equipment.

Watering Equipment

This type of equipment differs in two parameters, this section and the material used for the manufacture of the hose. If we talk about the section, then the most popular is the diameter of 13 mm, under it produced most of the irrigation taps.

Although the owners prefer a crane for a 3 4 inch hose for irrigating large areas, it is about 20 mm.

Accordingly, the hoses come from a larger diameter.

- As for the material, the range on the market impresses with its diversity, here it really is for every taste and budget.. The most affordable are plastic products. Here, both price and weight are the lowest. But such equipment will not serve for a long time. At the bends, the walls will also crack when using hard water, from the inside the surface is covered with lime.

- Rubber products deservedly considered the patriarchs of the dacha irrigation. The material is quite durable, elastic and not afraid of wrinkles. In the durability of rubber, of course, exceeds plastic, but inferior to nylon and PVC.

- Products made of nylon have long been considered the highest quality and durable. But they have one serious drawback, this material does not tolerate temperature drops. Hot water is especially dangerous for nylon; at elevated temperatures, the material becomes soft, with the result that strength is significantly reduced.

- The modern hose made of PVC and additionally reinforced with fiberglass is deservedly considered the king of irrigation hoses.. He is not afraid of temperature drops, as well as changes in pressure in the system.

Plumbing equipment

Everything is quite simple here, the connection of the hose to the tap in the kitchen or in the bathroom is carried out by flexible polymer, in some cases, rubber hoses in metal braid. The docking itself is carried out by means of a hermetic threaded pipe connection. Hoses are available for hot and cold water, respectively, they are marked with a red or blue stripe.

Tip: when purchasing both a water and gas connecting hose, its length should be slightly larger than the distance between the connection points. In no case should the sleeve be mounted tightly, the instruction requires that the hose be slightly slack.

Gas equipment

Any gas equipment has always been treated with special responsibility, because the breakdown of the water supply system or irrigation system threatens to flood its neighbors or soak it up. An accident on the gas pipeline could have much more serious consequences, including a real explosion.

Material for gas compounds also comes in 2 types. The rubber sleeve, of course, has a low cost, but it will serve in the kitchen no more than 5 years. The gas hose in the steel sheath is made of special heat-resistant polymers, plus on top it is reinforced with a reinforcing jacket made of stainless steel. Any gas equipment, be it a hose nozzle on a tap, a tap itself or a connecting hose, is marked in yellow.

Tip: before buying a connecting hose, it will not be superfluous to clarify in the gas service what types of equipment are allowed in the area. The fact is that the installation of a rubber compound is not permitted everywhere. And in order not to run into a fine later, it is better to raise local regulatory documents.

General principles of installation

We have already found out that the connections differ significantly among themselves depending on the purpose of the reinforcement, respectively, and the methods of installation of this reinforcement will be different.

If we talk about watering devices, then before you attach the hose to the faucet, you need to fasten the connecting nipple on this hose. The connection node with the crane can be docked with a thread or simply put on the fitting.

Tip: if it is planned to use interchangeable tips of a different type, in addition to a sprinkler tap, then it is better to immediately purchase connectors with a hitchhiking.

To fix the connector to the end of the irrigation sleeve, you need to cut off the edge of the sleeve as much as possible and put a clamping nut on it. After that, you should tightly, until it stops, put the soft hose on the connector nozzle and tighten the nut that was previously attached.

This method is currently the most practical, since, unlike crimping, this mounting unit can, if necessary, be easily disassembled and moved to a new location.

In order to power several watering hoses from a single node, there is an adapter or splitter for hoses with a tap. The supply line, as a rule, is joined to such an adapter through a reliable threaded connection. All the other sleeves extending from the adapter, it is much more convenient to dock in the usual way, putting the hose on the pipe and securing it with the help of a simple metal clamp.

As for the plumbing system with increased pressure, here the installation instructions are also quite simple. Initially, of course, you should dismantle the old mixer and clean the installation site. In this case, we will proceed from the fact that everything is installed and connected with flexible hoses.

First, the flexible hoses are connected to the mixer. Before connecting the hose to the tap, check for rubber gaskets and, on the open part of the thread, wind several turns of the sealing fum tape. The tapes need to be wound so that the thread twists tightly and, when fully screwed in, a part of the tape is squeezed out.

If we are talking about connecting the mixer in the kitchen, then experts advise to install a special splitter for hoses with a tap on the cold water main. It is useful for the subsequent connection of water filters and washing machines. Next, the mixer is attached to the sink, the hoses are connected to the highway.

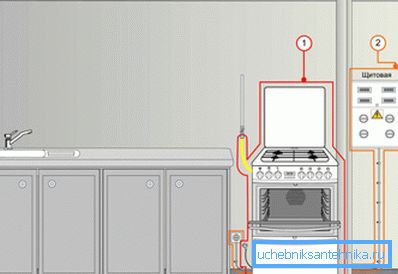

Compared to watering and plumbing, gas hoses are the easiest to connect, but dilettantes still don’t have to do it, because the mistake can be expensive. The diameter of the hose on a standard gas oven should be at least 10 mm, otherwise there will not be enough gas for all 4 burners and an oven.

Between the furnace and the sleeve, there must be a dielectric strip to avoid the accumulation of stray currents. Experienced gas workers advise, in addition to using fum-tapes, before connecting the hose to the faucet or stove, to lubricate the gaskets with ordinary soap, this will significantly increase the tightness. After installation, all connections need to be smeared with liquid soap solution, if there is a leakage, soap bubbles will be shown.

The video in this article shows some useful little things.

Conclusion

As you can see the choice and connection of various kinds of hoses is not so difficult as it may seem. But still it is better to entrust the installation of gas fittings and connections to specialists or, after installation, invite a specialist for inspection.